Rapid verification device and method for split type guided wave radar liquid level meter

A guided wave radar and calibration device technology, applied in the field of instrument control, can solve the problems of low efficiency and low accuracy, and achieve the effects of easy portability, avoiding waste, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

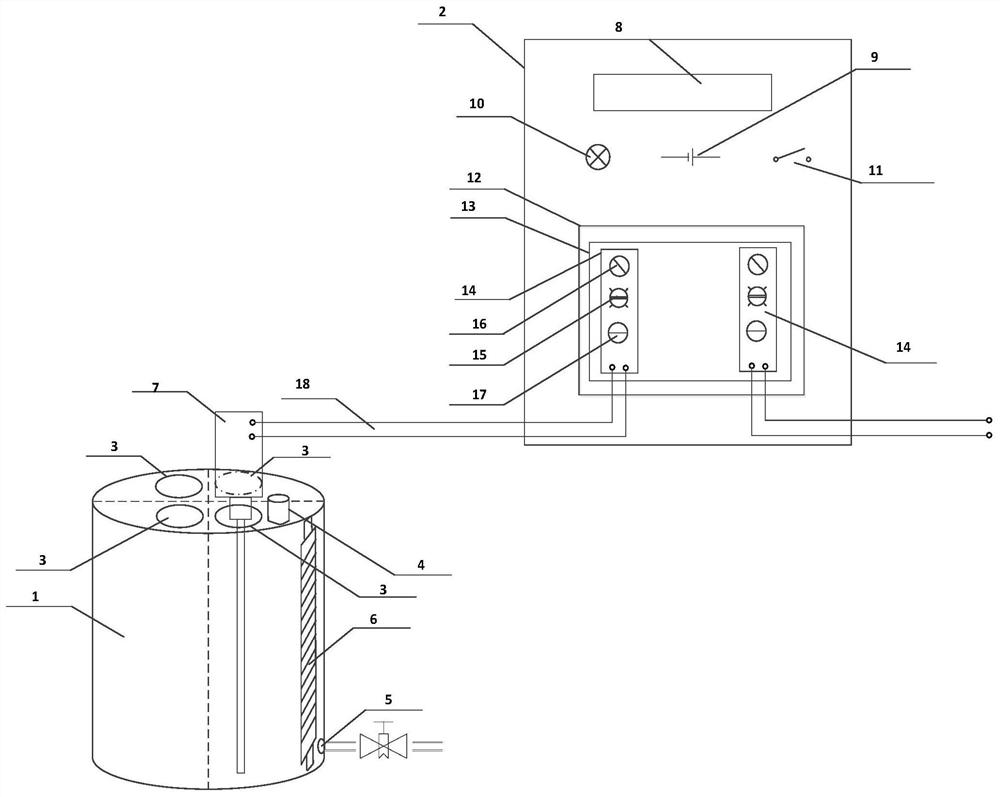

[0047] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0048] Such as figure 1 As shown, a rapid calibration device for a split-type guided wave radar level gauge provided by the present invention includes: a tank body 1, a base 2, a radar probe sensor interface 3, a medium injection port 4, a medium discharge port 5, a scale Board 6, radar probe sensor 7, display screen 8, battery 9, battery power indicator light 10, battery switch 11, secondary instrument rack installation interface 12, secondary instrument rack 13, secondary instrument 14, secondary instrument failure Alarm light 15, secondary instrument full point adjustment key 16, secondary instrument zero point adjustment key 17 and connecting cable 18.

[0049] The tank body 1 is made of transparent material, and the top surface of the tank body 1 is provided with a radar probe sensor interface 3 and a medium injection port 4 respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com