Flexible needle puncture mechanism for tail end of mechanical arm

A flexible needle and robotic arm technology, applied in the field of medical devices, can solve the problems of needle puncture accuracy, easy bending of the needle body, etc., and achieve the effect of avoiding puncture errors and preventing warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

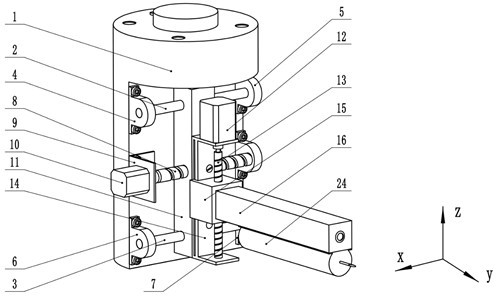

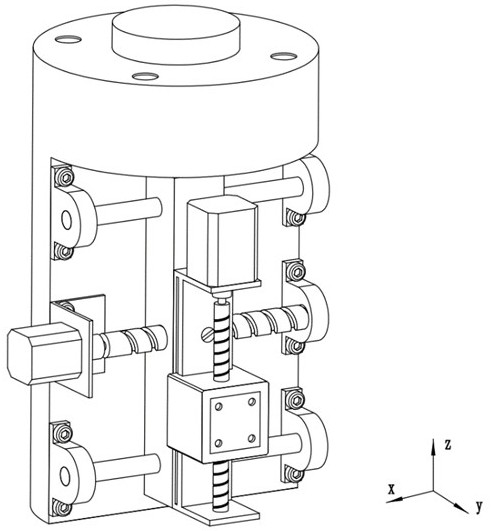

[0017] see figure 1 , a flexible needle puncture mechanism for the end of the mechanical arm, which consists of two parts: a fine-adjustment mechanism for the entry point and a flexible needle feeding mechanism; the fine-adjustment mechanism for the entry point is used to precisely adjust the position of the entry point of the flexible needle, and the flexible needle The puncturing mechanism realizes the function of driving the flexible needle to puncture the human body.

[0018] Further, a needle entry point fine-tuning mechanism used in the puncture mechanism at the end of the mechanical arm consists of a base (1), a light bar one (2), a light bar two (3), a light bar support one (4), a light bar Bracket two (5), light rod support three (6), light rod support four (7), motor support (9), x-direction feed motor (10), x-direction screw (8), x-direction slider ( 11), z-direction sliding table (14); the whole mechanism is installed at the end of the mechanical arm through the b...

specific Embodiment approach 2

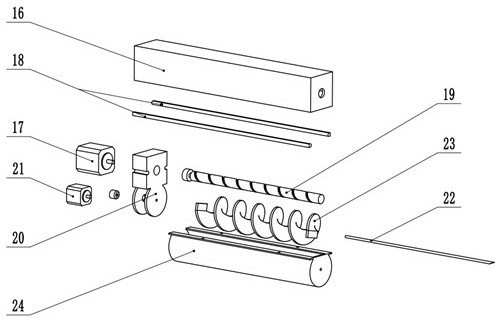

[0021] Through the reverse rotation of the puncture feeding motor (17), the needle seat (20) is fed in the opposite direction along the slideway, and this motion is continued until the flexible needle (22) completely withdraws from the human body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com