Metering instrument upper shell assembly automatic assembling technology and implementation method thereof

A measuring instrument and automatic assembly technology, which is applied to the automatic assembly process of the upper shell components of the measuring instrument and its realization, can solve the problems of finger injury, poor consistency, and many people, and achieve the effects of smooth production, improved product quality, and reasonable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

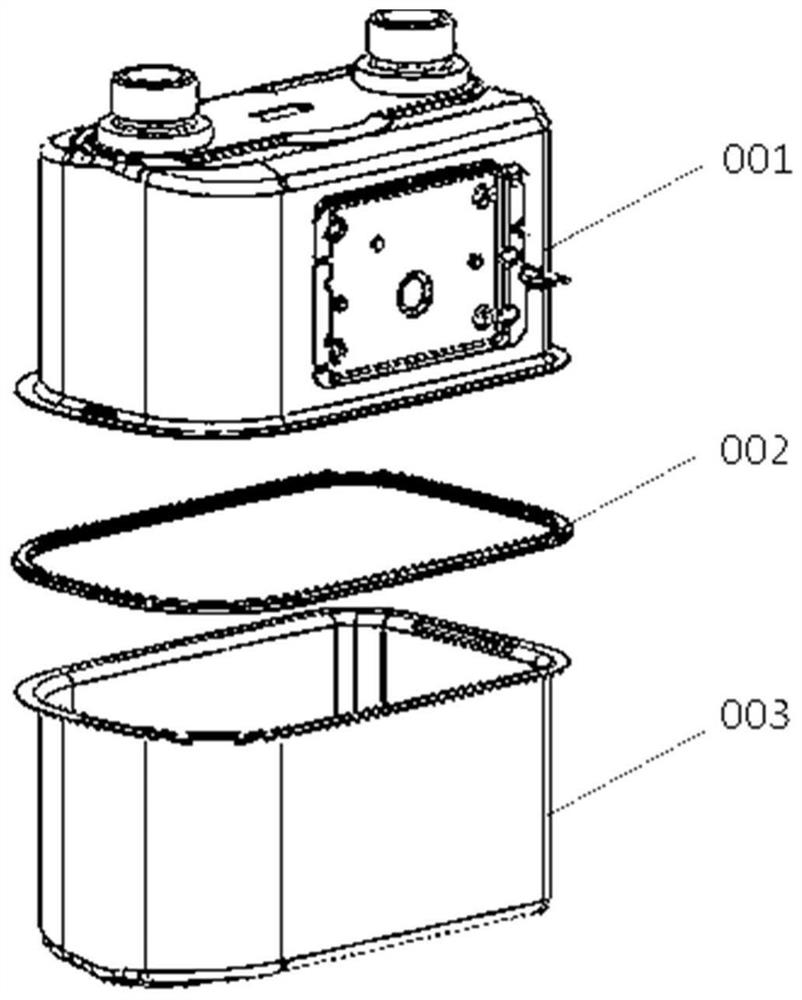

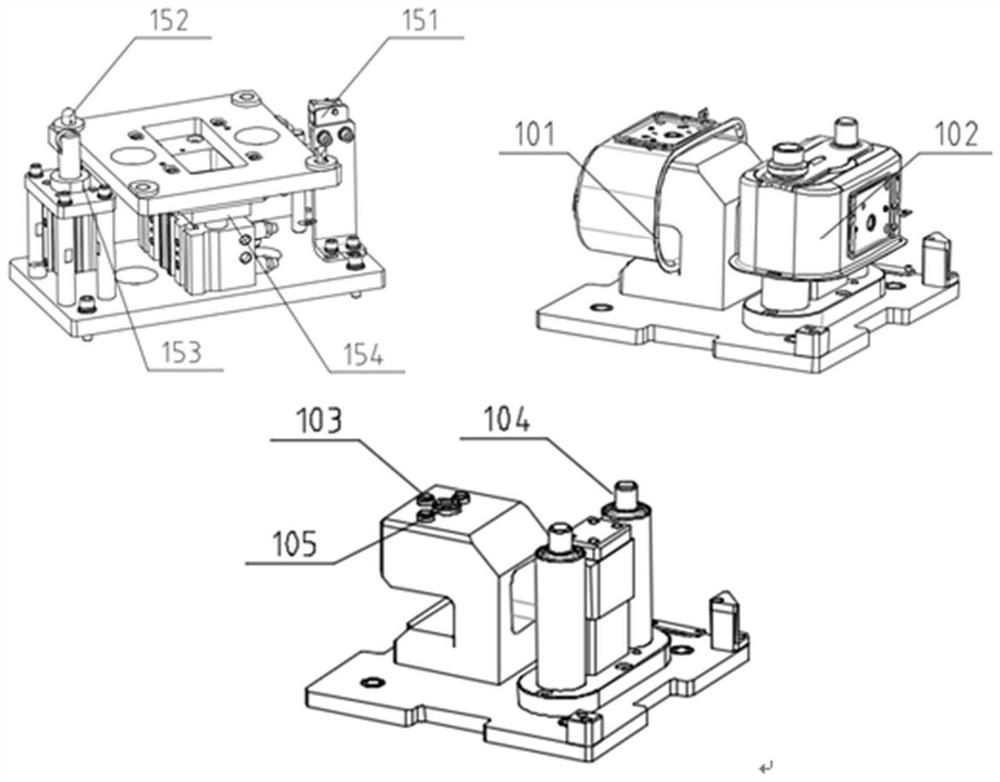

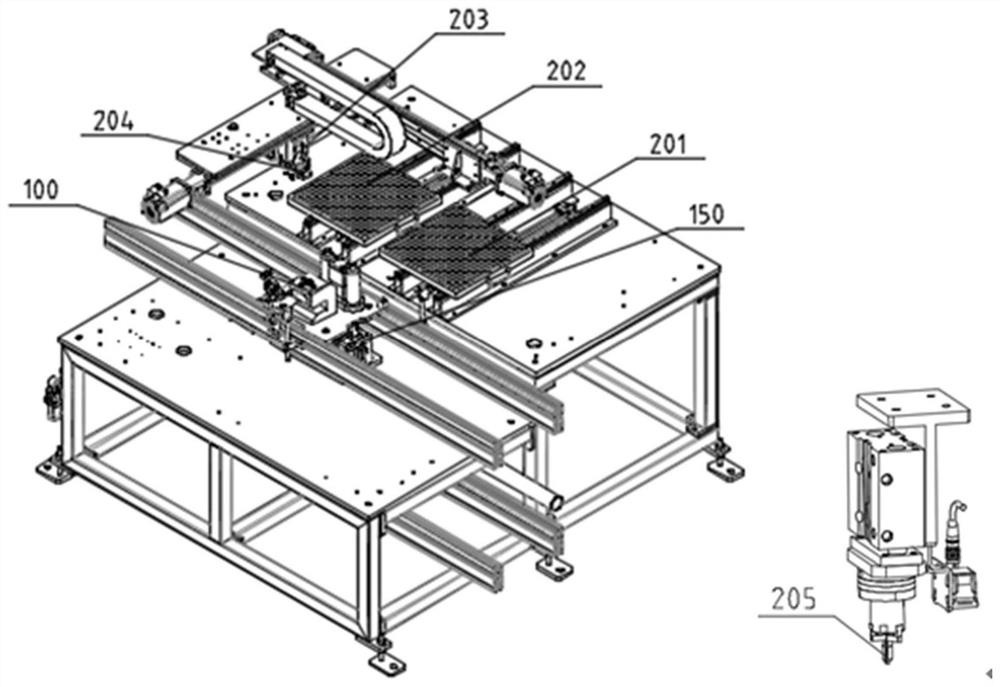

[0072] The present invention provides an automatic assembly process of the upper shell assembly of a measuring instrument and its realization method. The proposed process flow can be summarized as follows: the upper cover 005 is put into the accompanying tooling 100 - the shaft sleeve 007 is on the line - the bottom plate 006 is on the line - ---Bottom plate 006 riveting----shaft sleeve 007 riveting----washer 009 transfer----top cover 005 flip transfer----pipe joint 004 transfer----pipe joint 004 riveting- ---The upper casing assembly 001 was rolled off the assembly line.

[0073] In the above-mentioned automatic assembly process and implementation method of the upper shell assembly of the measuring instrument, the assembly line management and control system 650 connects and controls the roller conveying line device 700, the bushing on-line device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com