Grinding device for snakegourd seed processing

A technology of melon seeds and grinding mechanism, which is applied in the direction of metal processing equipment, grinding machines, manufacturing tools, etc., can solve the problems of limited scope of application, time-consuming and inconvenient operation, etc., achieve uniform and sufficient grinding, strong practicability, and expand the scope of application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

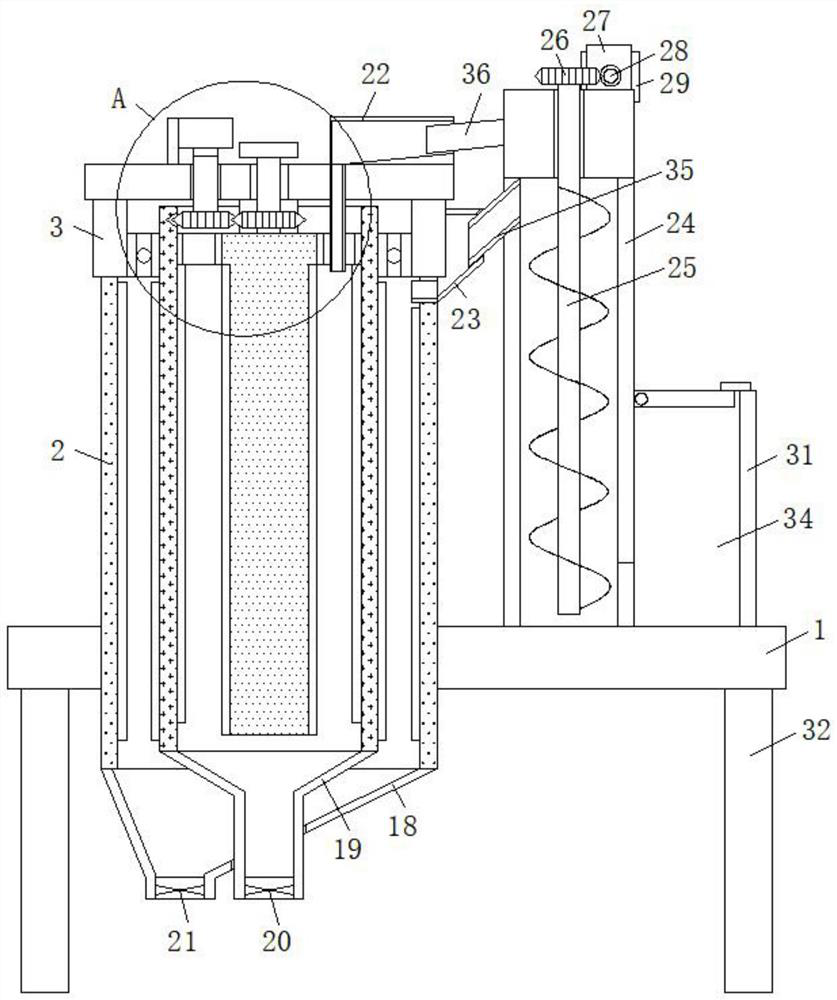

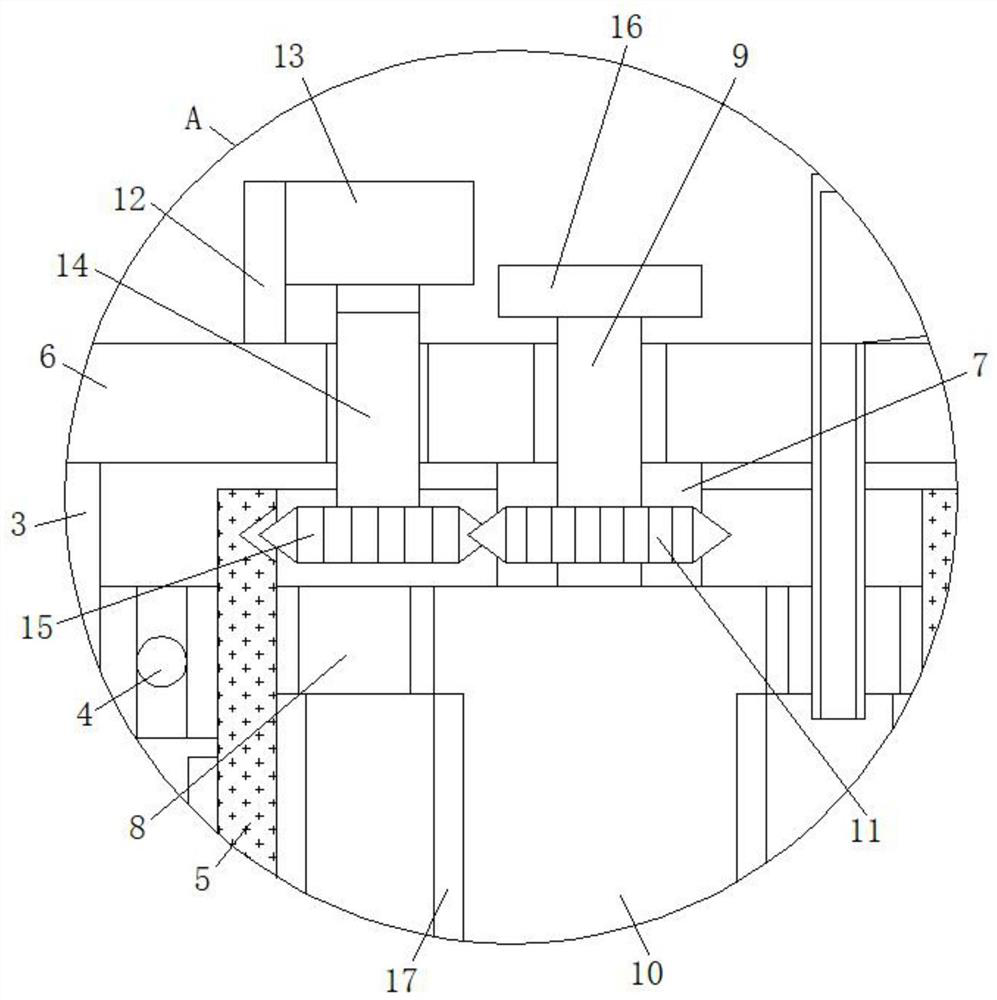

[0028] refer to Figure 1-3 , a kind of milling device for millet seeds processing, comprising a working plate 1, a sorting and grinding mechanism is arranged in the plate body of the working plate 1, and a uniform feeding mechanism is arranged on the top side, and the sorting and grinding mechanism includes a grinding cylinder-2, an annular mounting plate 3. Grinding barrel 2 5, circular plate 6, circular ring plate 8, grinding column 10, gear 1 11, motor 1 13 and gear 2 15, and the uniform feeding mechanism includes a feeding box 24, a spiral stirring shaft 25, and a worm 28 , motor two 29 and material storage box 31, the grinding tube one 2 is vertically fixedly arranged in the plate body of the working plate 1, the ring mounting plate 3 is fixedly connected on the top side of the grinding tube one 2, and the inner side of the ring mounting plate 3 is equipped with a bearing 4. The grinding cylinder 2 5 is installed inside the bearing 4, the bottom side of the circular plat...

Embodiment 2

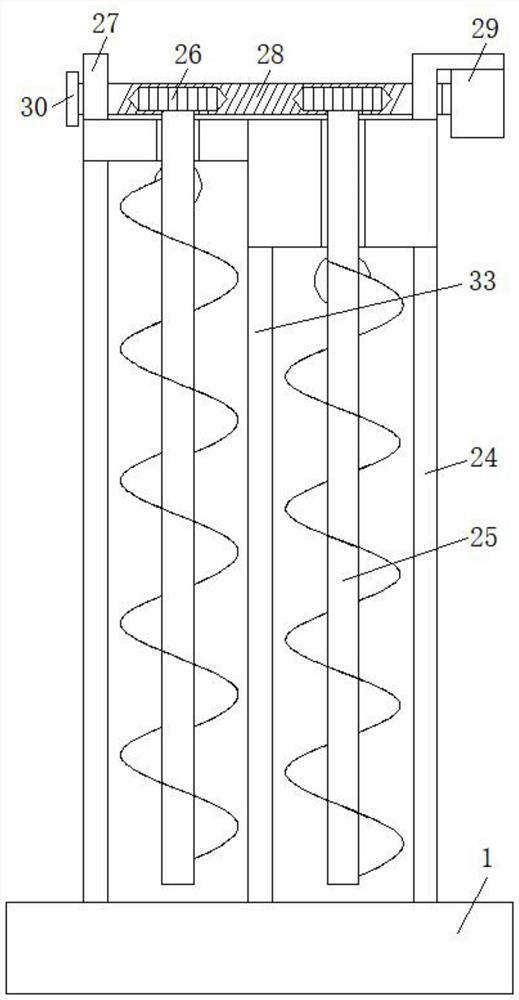

[0031] Such as Figure 1-3 As shown, the present embodiment is basically the same as Embodiment 1, and the more optimized place is that the feeding box 24 in the uniform feeding mechanism is fixedly arranged on the top side of the working plate 1, and the inner side of the feeding box 24 is vertically fixedly arranged with Partition one 33, the spiral stirring shaft 25 is connected with the top wall of the feeding box 24 in rotation, and the spiral stirring shaft 25 is vertically provided with two, and is respectively positioned at the both sides of partition one 33, and the top is all fixedly connected with worm gear 26 , the top side of the feeding box 24 is fixedly connected with an installation riser 27, and there are two installation risers 27 vertically, the worm 28 is rotated and arranged between the two installation risers 27, and the two worm wheels 26 are all connected with the worm 28 meshing connection, the second motor 29 is installed on one side of the vertical p...

Embodiment 3

[0034] Such as Figure 1-3 As shown, the present embodiment is basically the same as Embodiment 1, and the more optimized part is that the cylinder outside of the grinding column 10, the inside and outside of the cylinder of the grinding cylinder two 5, and the inside of the cylinder of the grinding cylinder one 2 are provided with Frosted wall 17, a first grinding chamber is arranged between the outside of the cylinder of grinding column 10 and the inside of the cylinder of grinding cylinder two 5, and between the outside of the cylinder of grinding cylinder two 5 and the inside of the cylinder of grinding cylinder one 2 is provided with Second grinding cavity.

[0035] In this embodiment, the surface of the Trichosanthes seeds is polished through the frosted wall 17, so that the Trichosanthes seeds can be polished in real time after they come into contact with the frosted wall 17, the operation is simpler, and multiple Trichosanthes seeds are polished at the same time The g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com