Preparation method of polishing disc for polishing superhard substrate slice and precise polishing method

A technology for polishing discs and negatives, applied in grinding/polishing equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of time-consuming and labor-intensive, difficult to control and guarantee the processing quality of substrate sheets, increase costs, etc., and achieve an average thickness Small difference, reduced mechanical polishing time, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

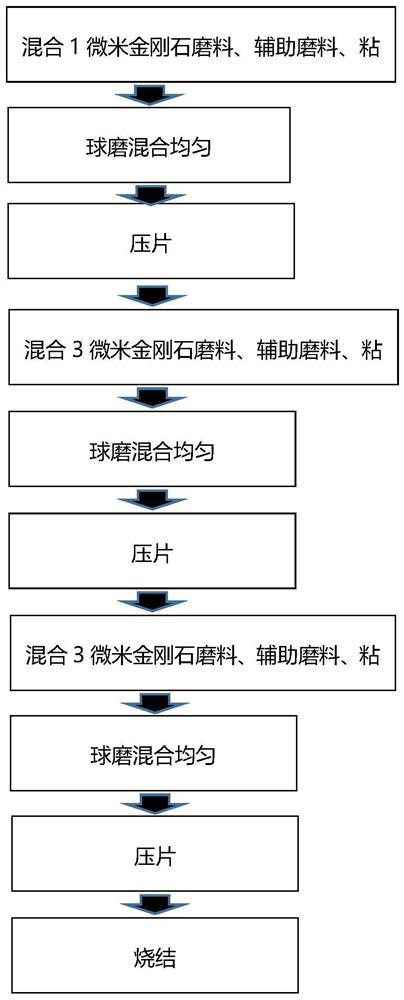

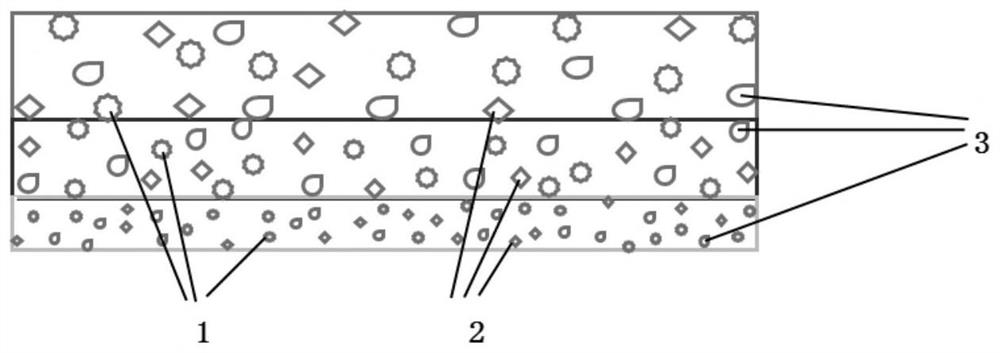

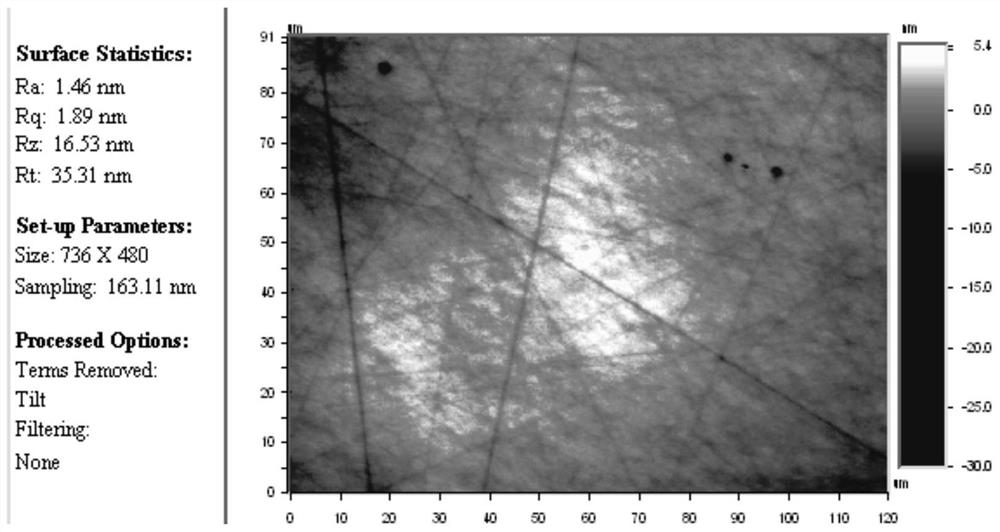

[0033] Aiming at the above-mentioned difficulties existing in the prior art, the present invention provides a method for preparing a polishing disc for superhard substrate polishing, such as figure 1 As shown, by using a multi-layer composite polishing disc to precisely polish the substrate, compared with the traditional substrate polishing process, the process flow is greatly simplified, and a substrate polishing sheet with a better surface shape is obtained. The polished substrate The average thickness difference is small, and the bending warpage is low.

[0034] The three-inch superhard silicon carbide substrate sheet adopts the three-layer composite polishing disc of the present invention to carry out precision mechanical polishing, and the abrasive material of the three-layer polishing disc is 1 micron, 3 micron and 6 micron diamond and percent of 60 volume percent Alumina with the same particle size of 10% by volume is sintered by ball milling and sintering polyester mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com