Patents

Literature

38results about How to "Improve facial shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

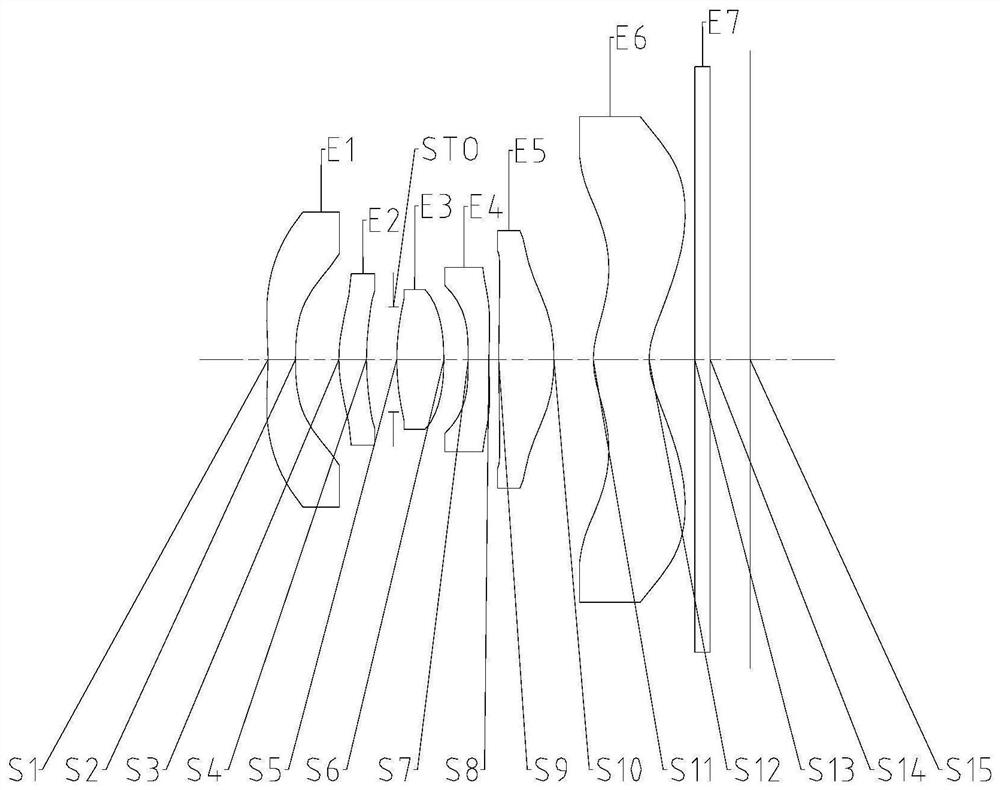

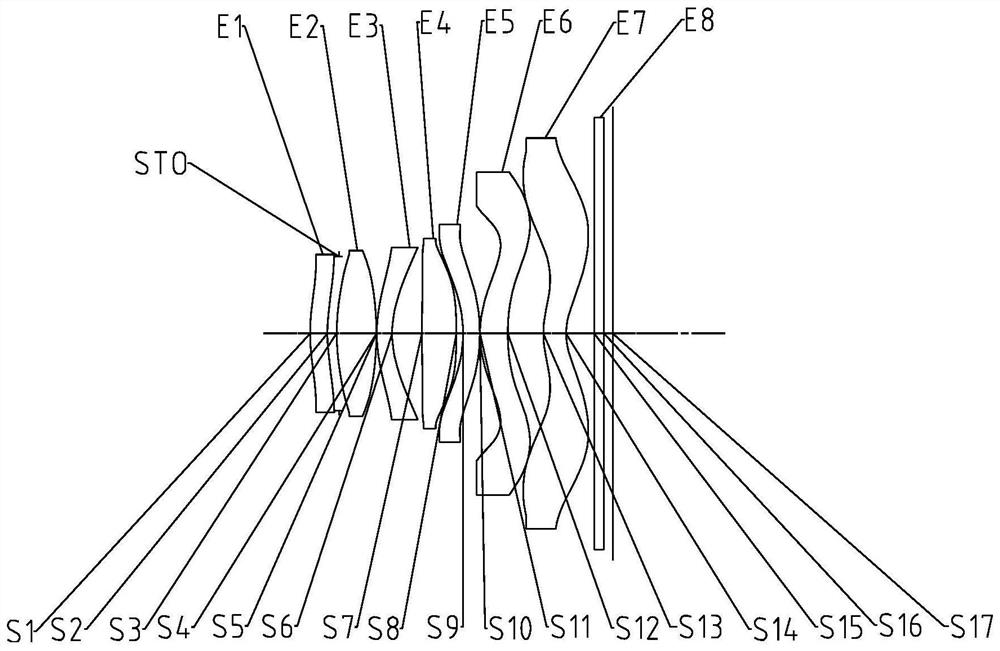

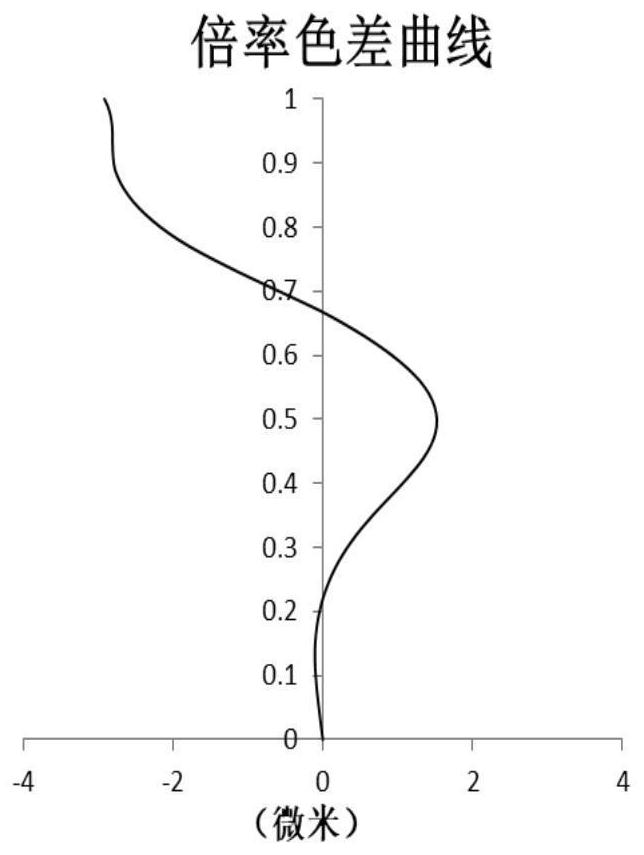

Optical imaging camera lens

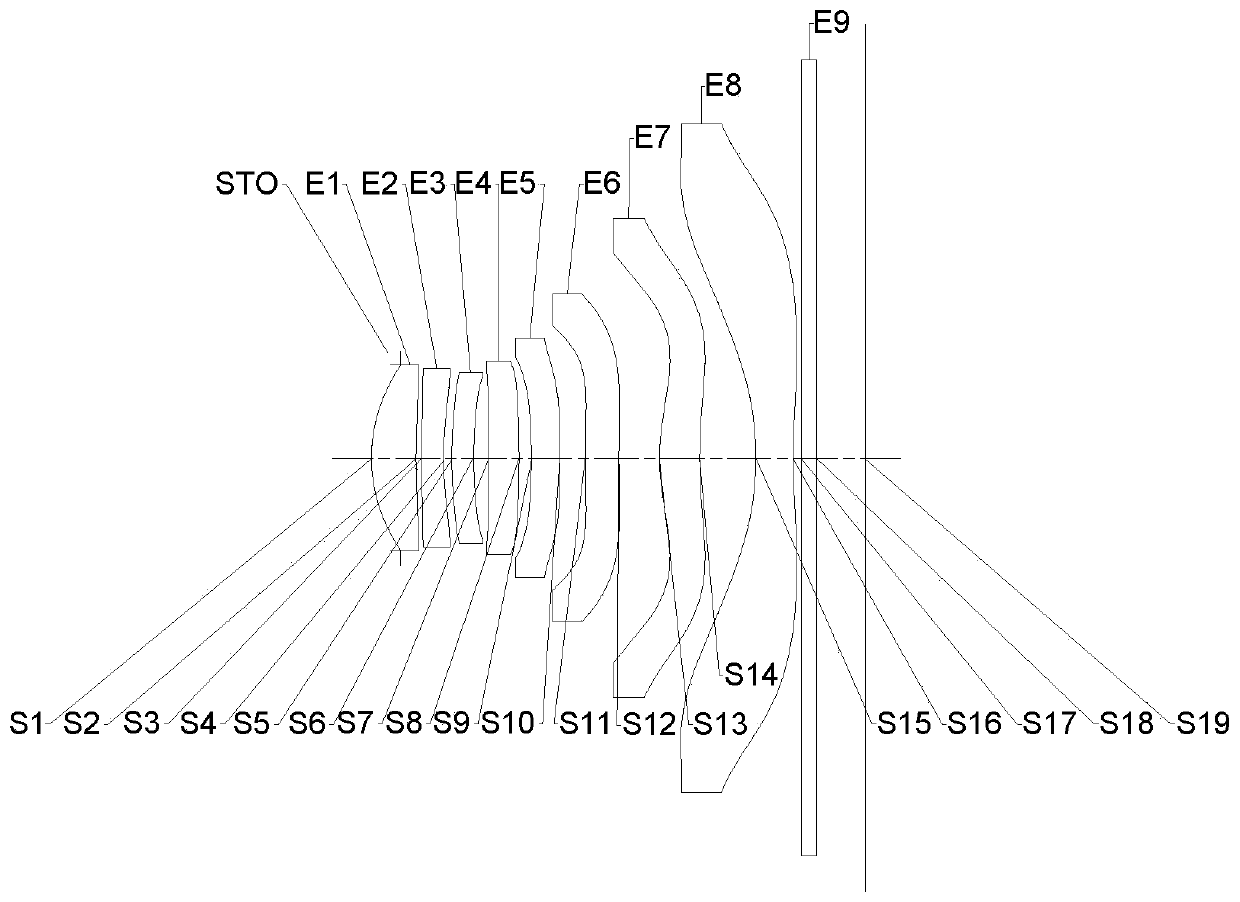

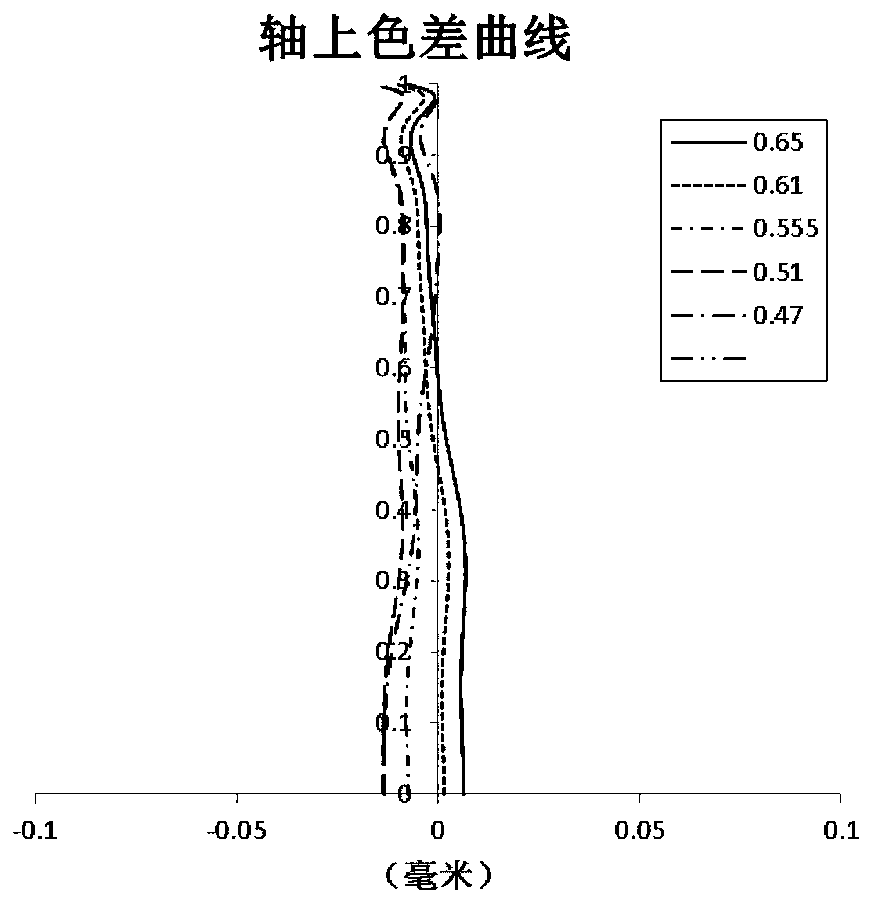

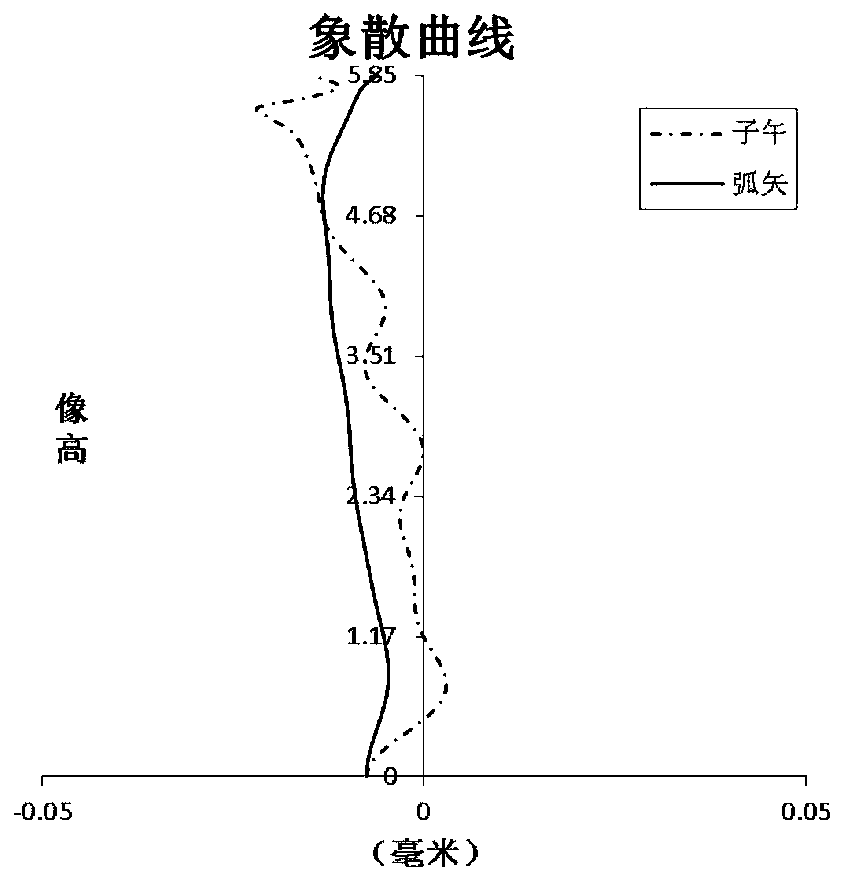

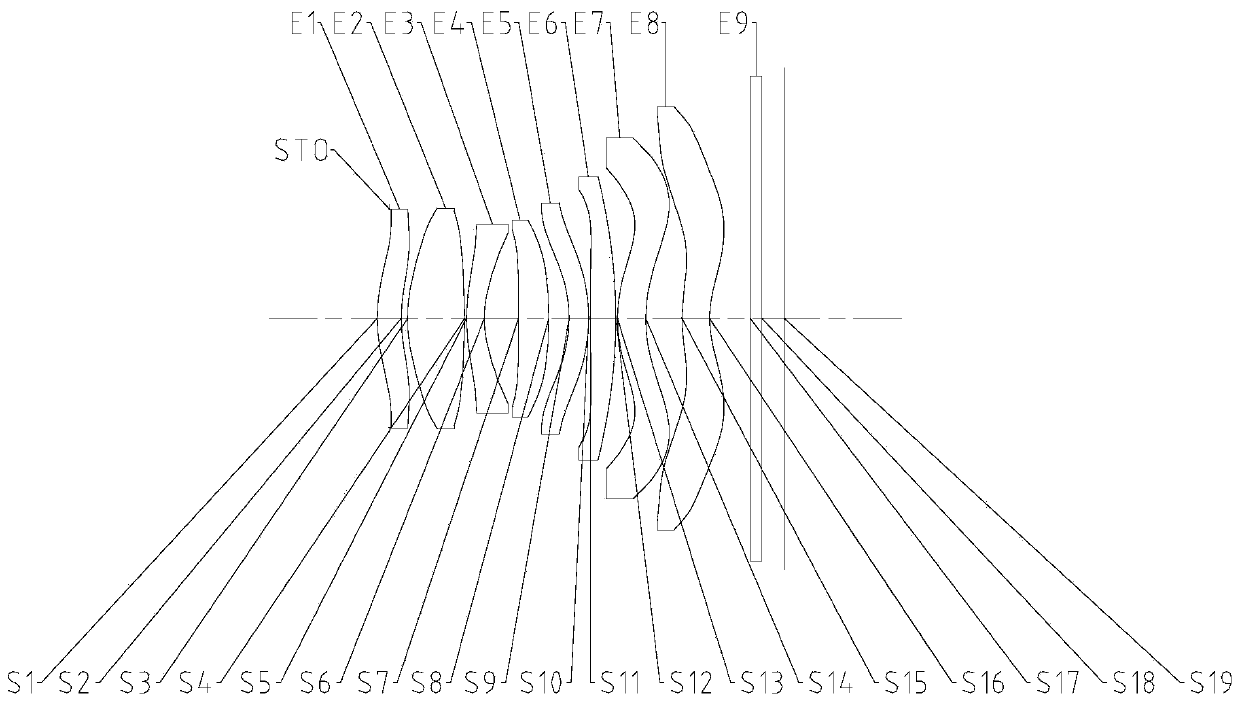

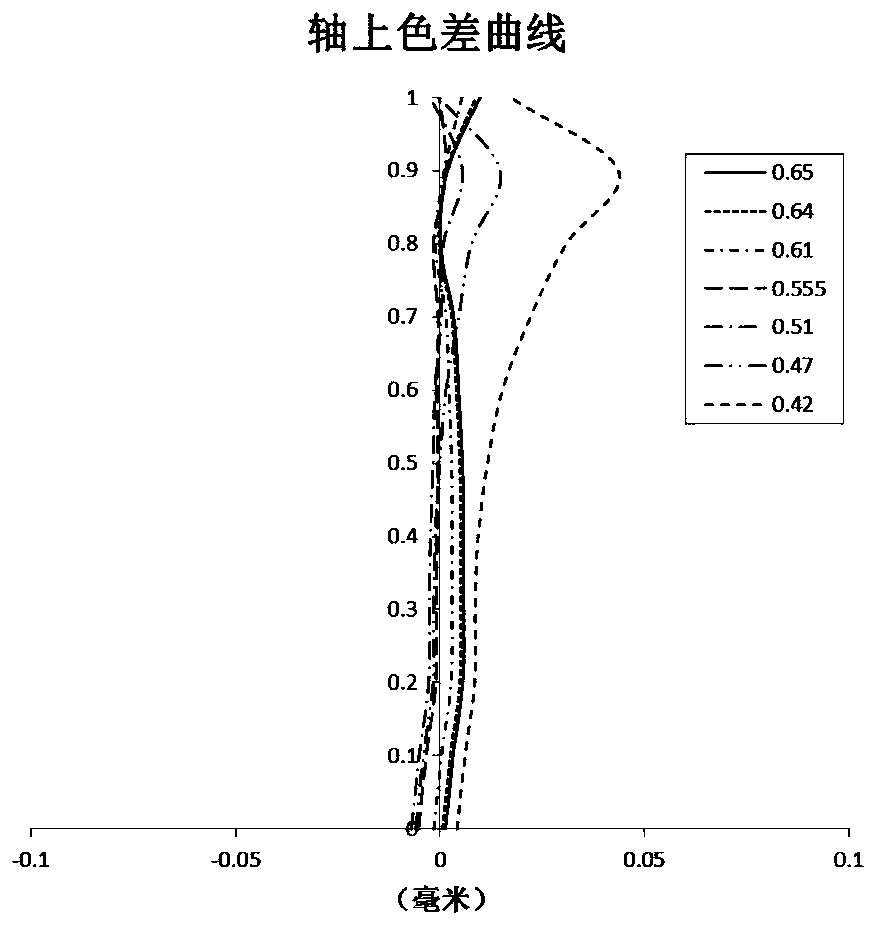

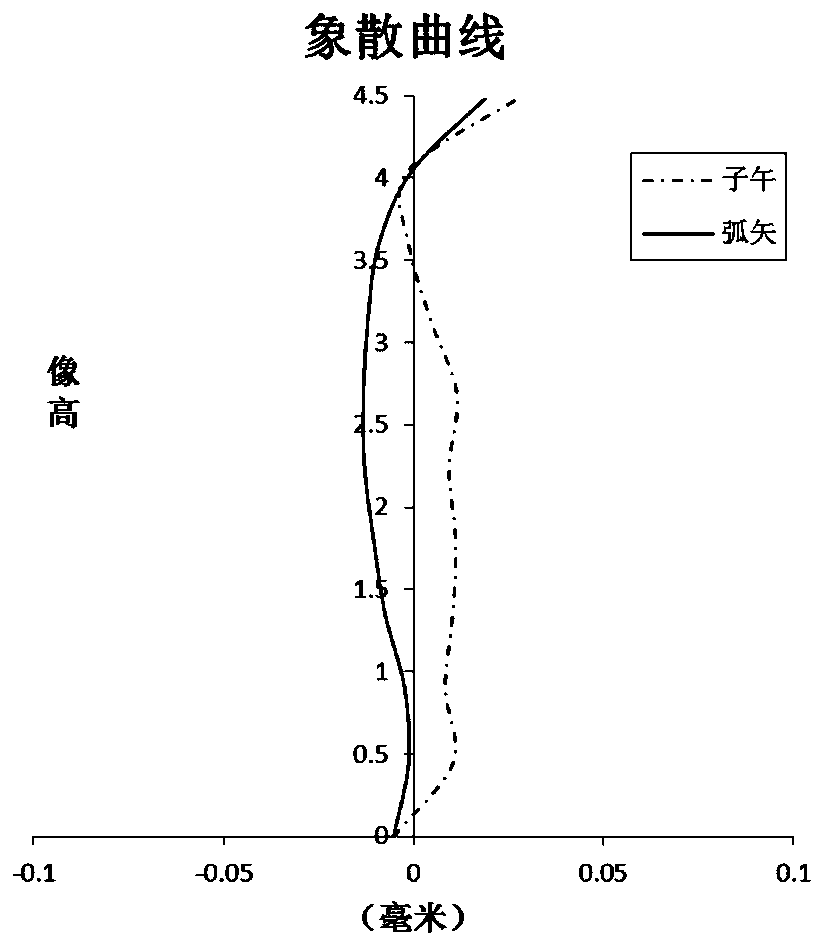

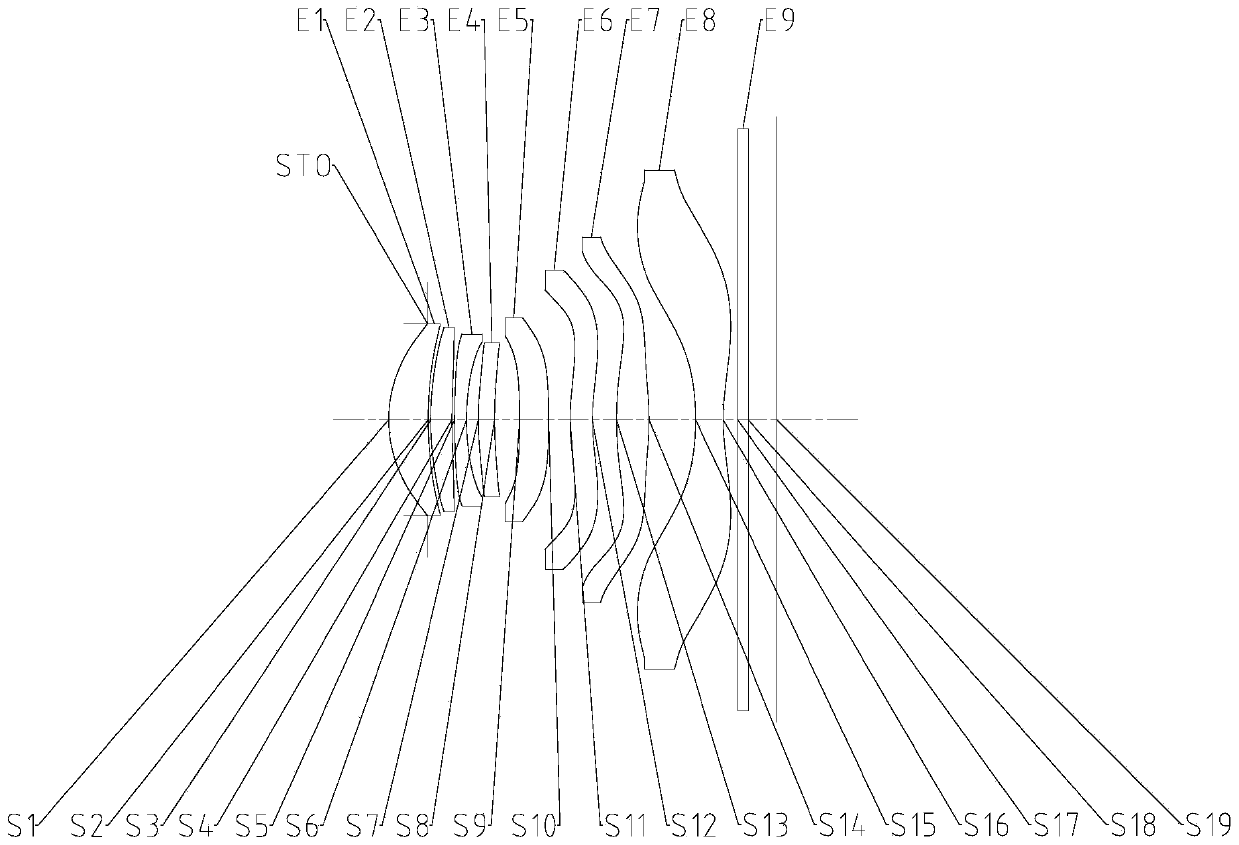

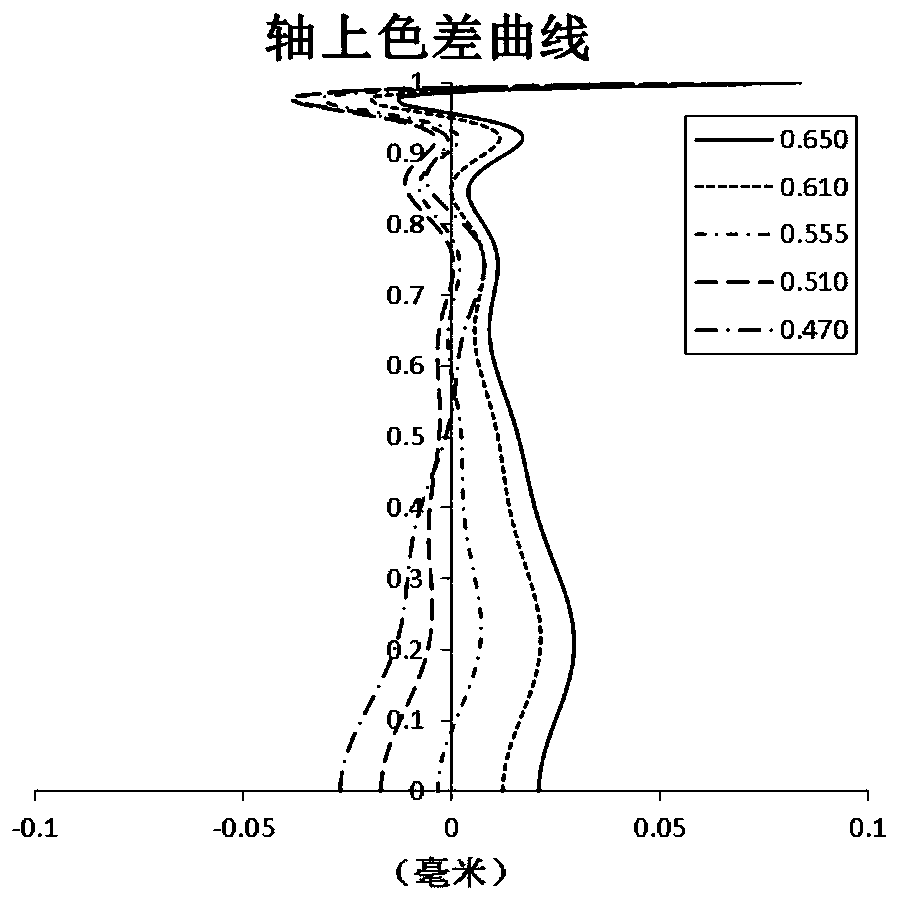

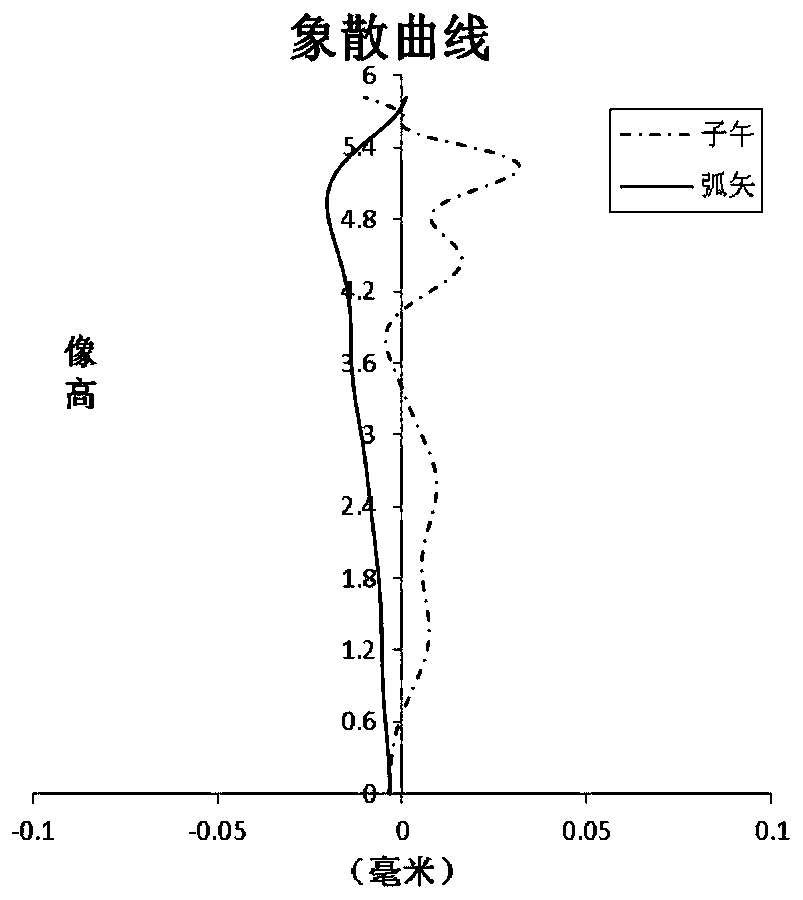

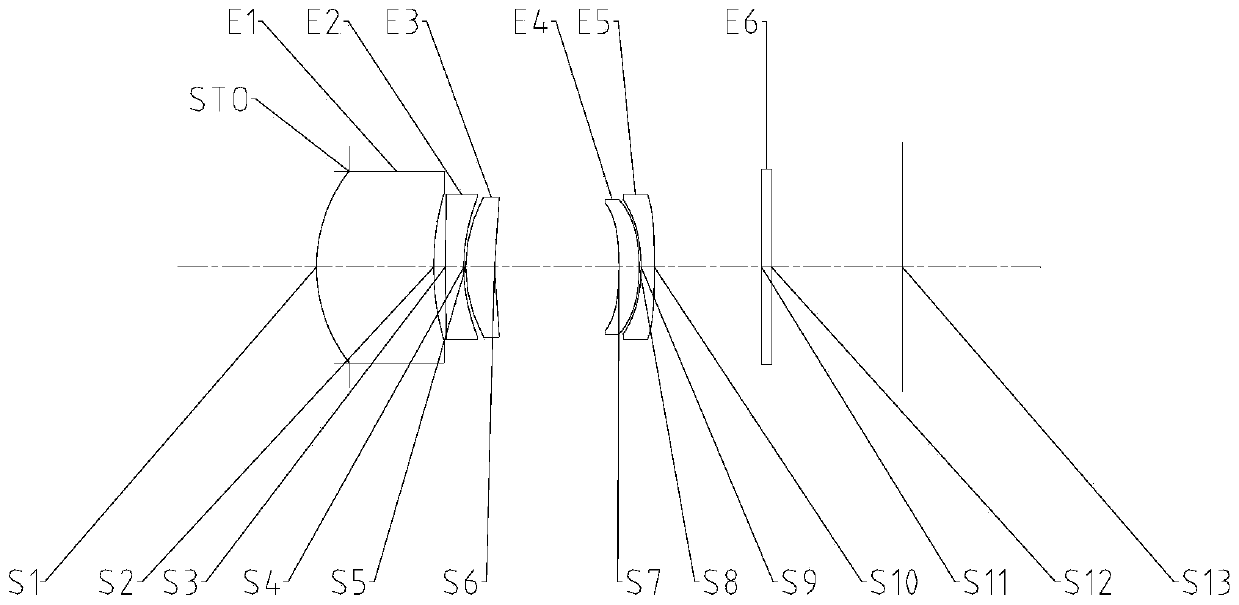

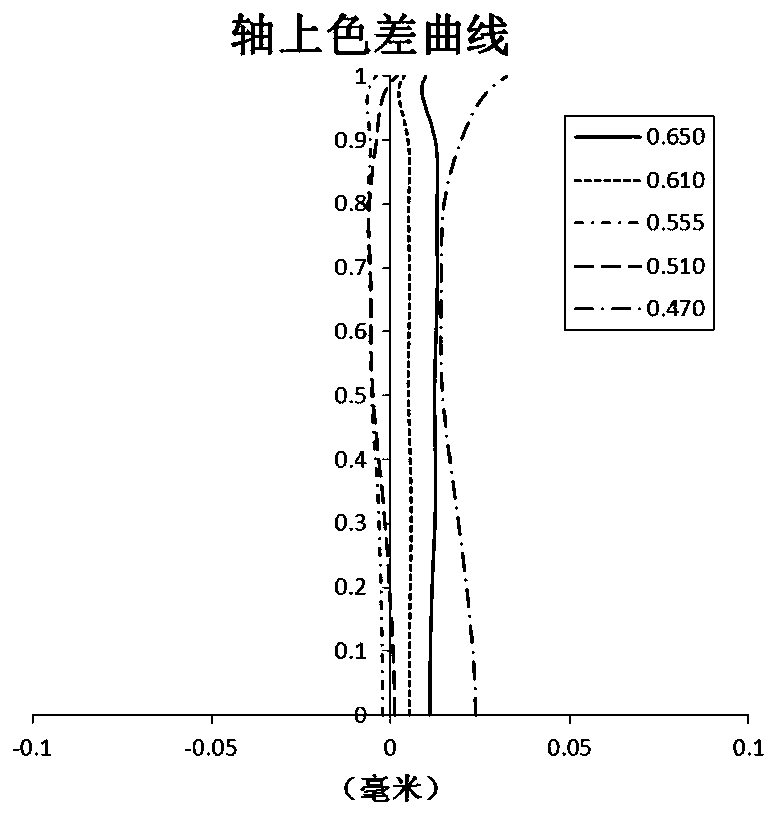

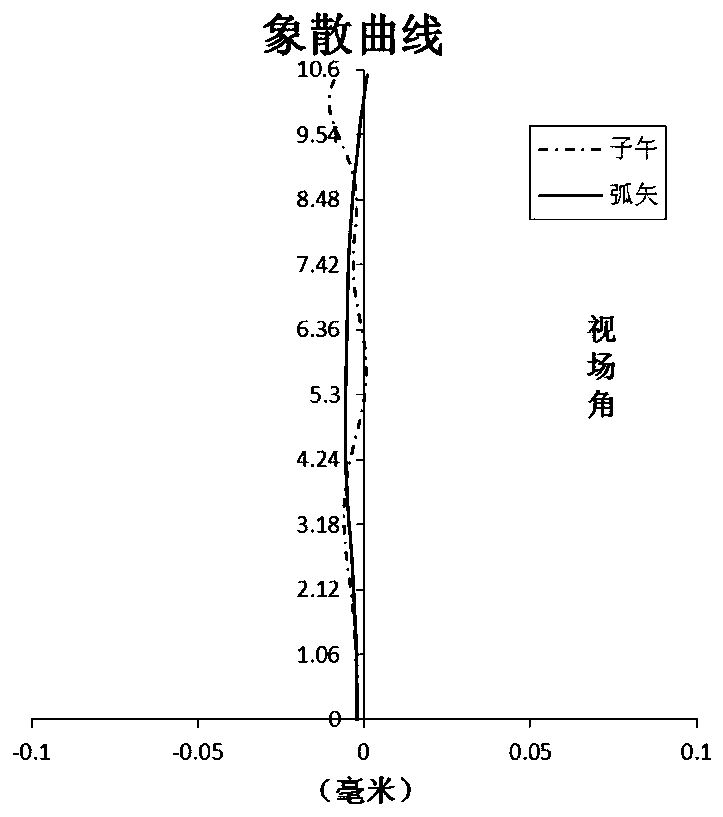

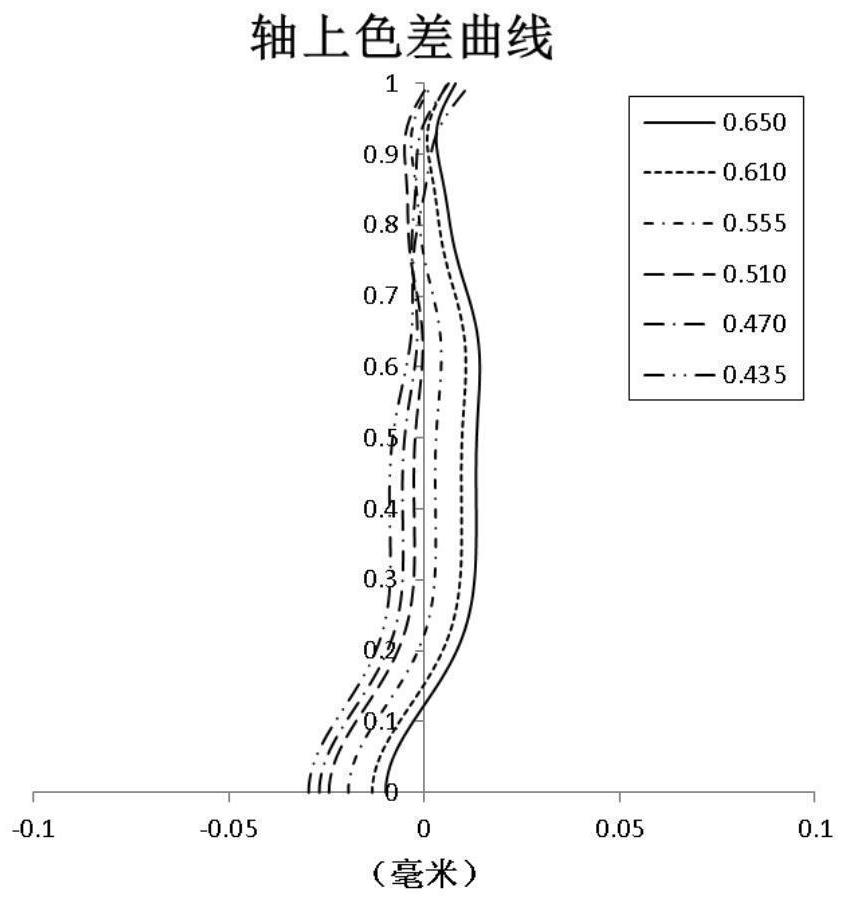

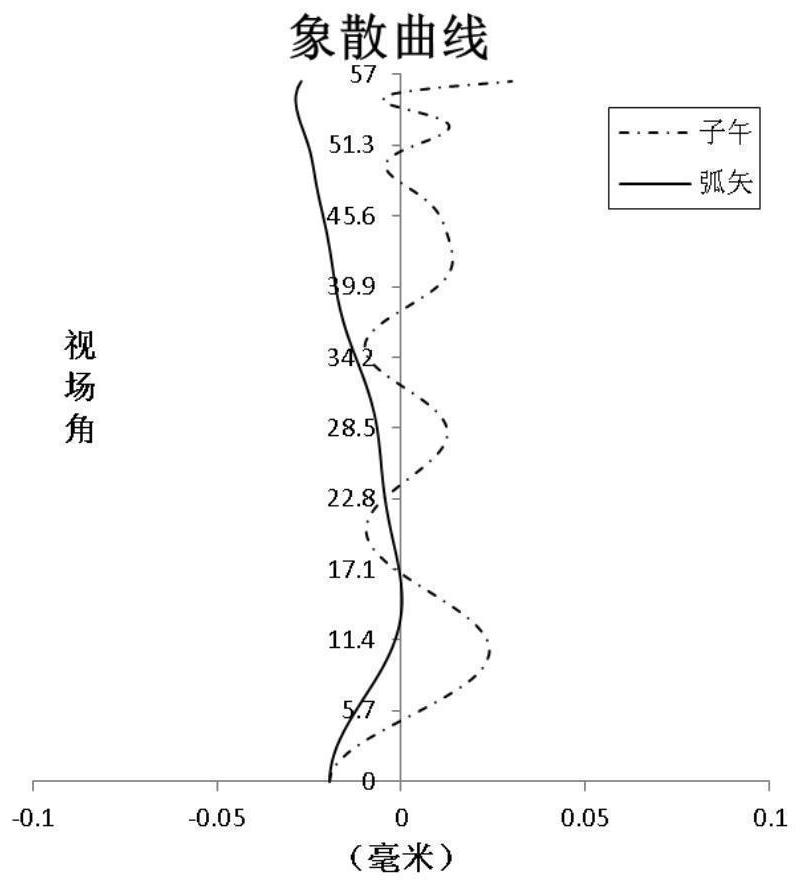

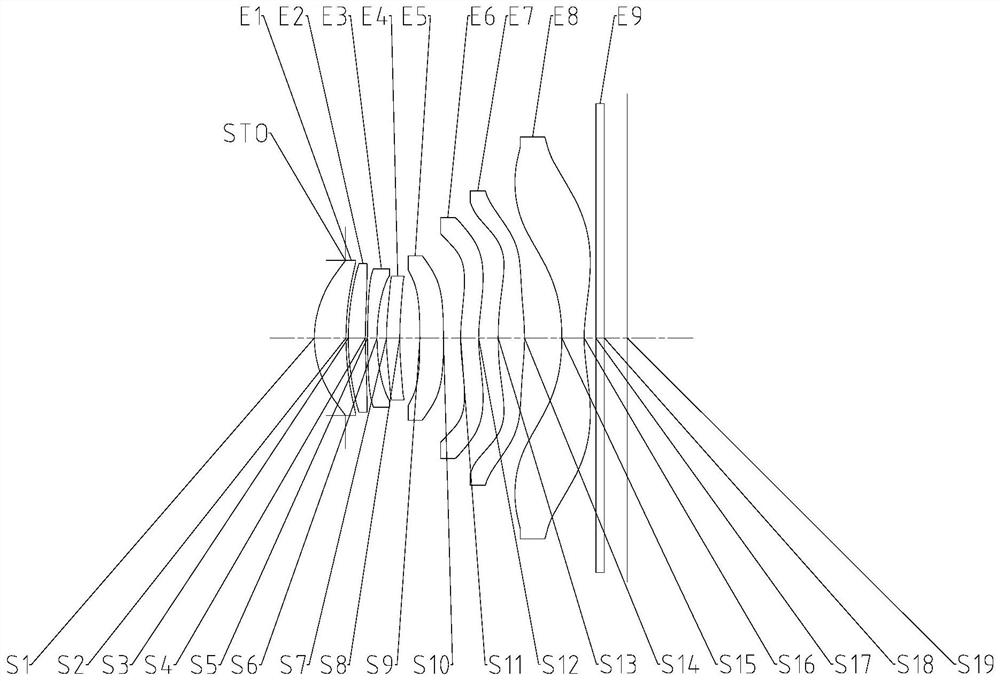

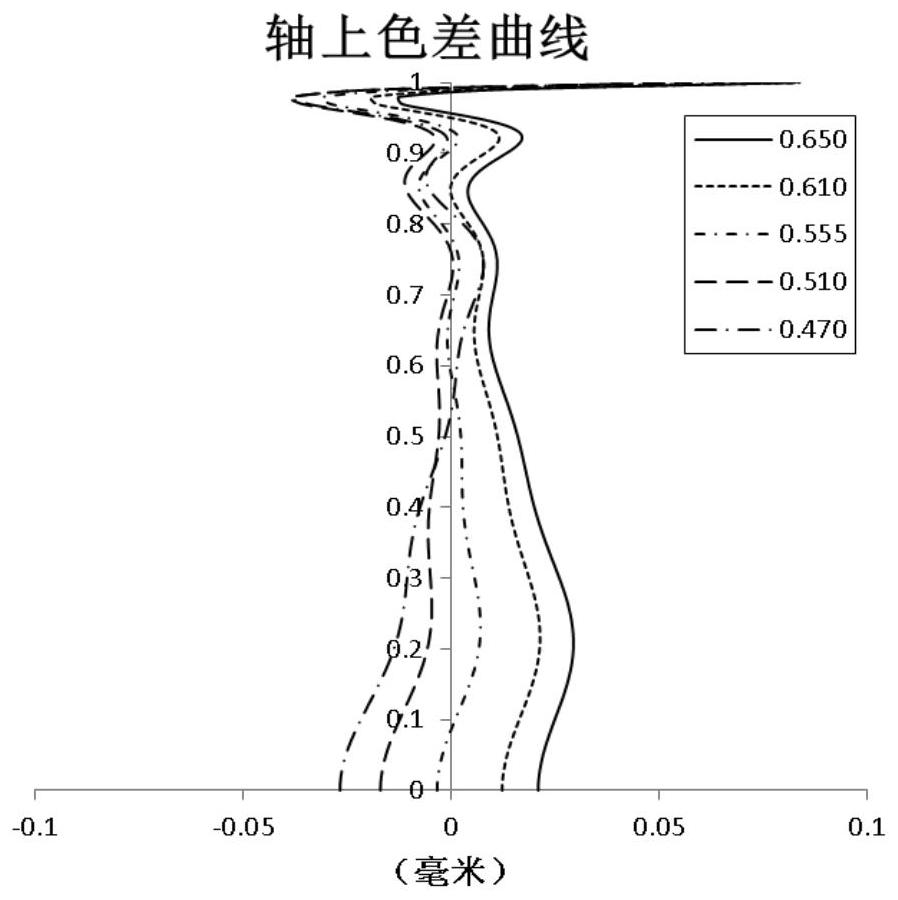

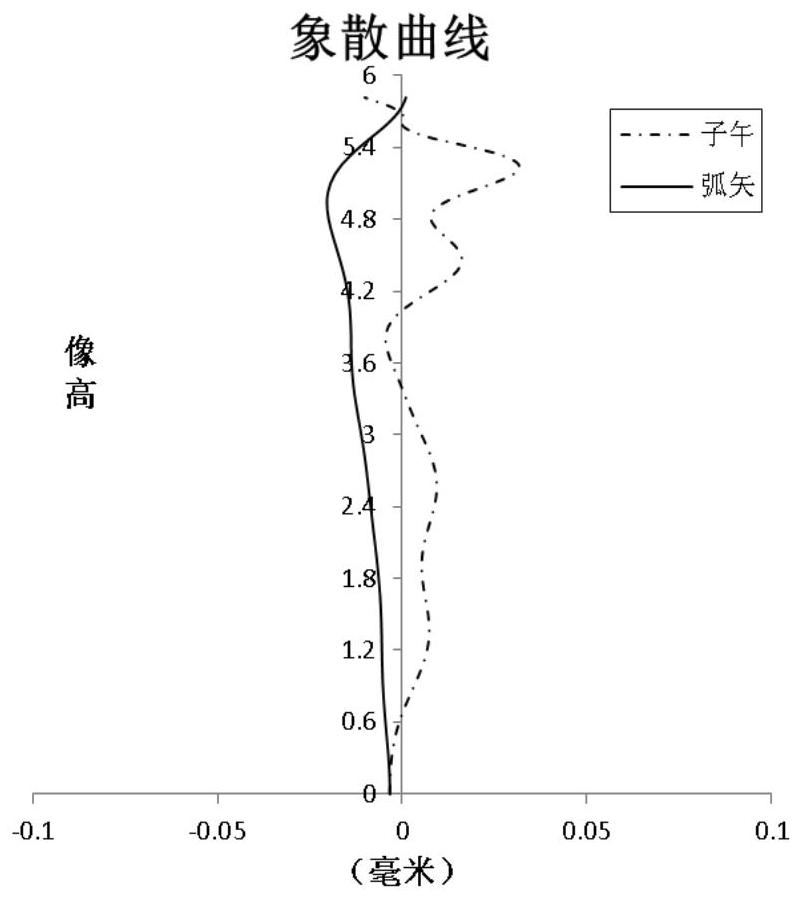

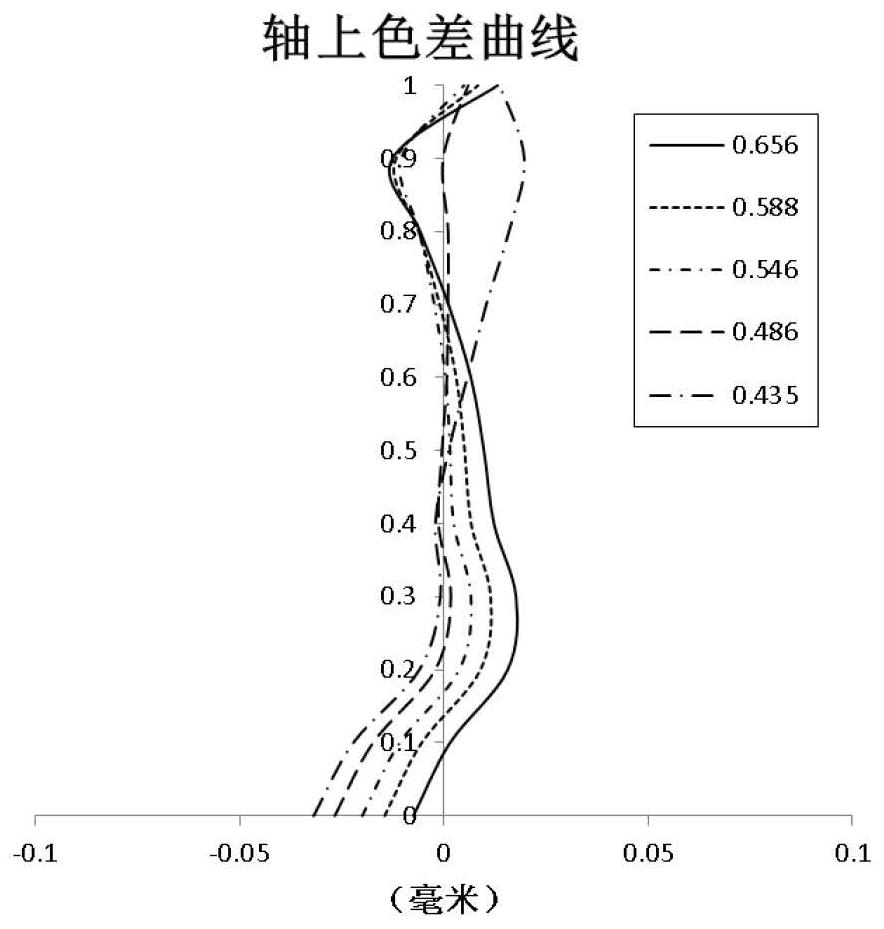

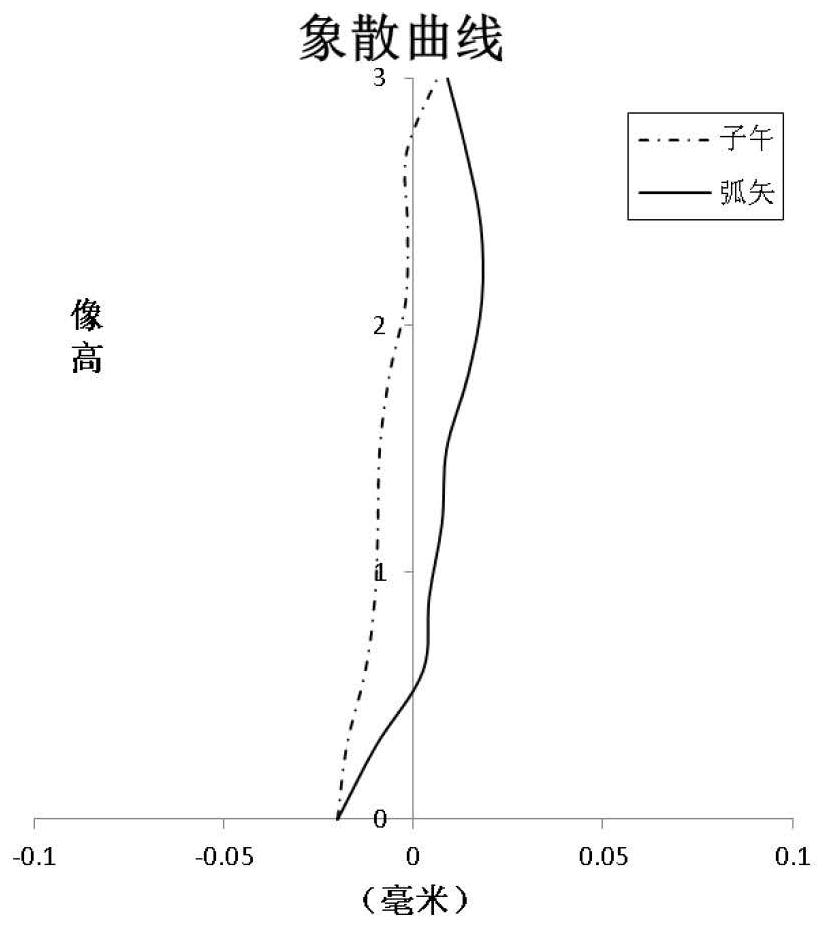

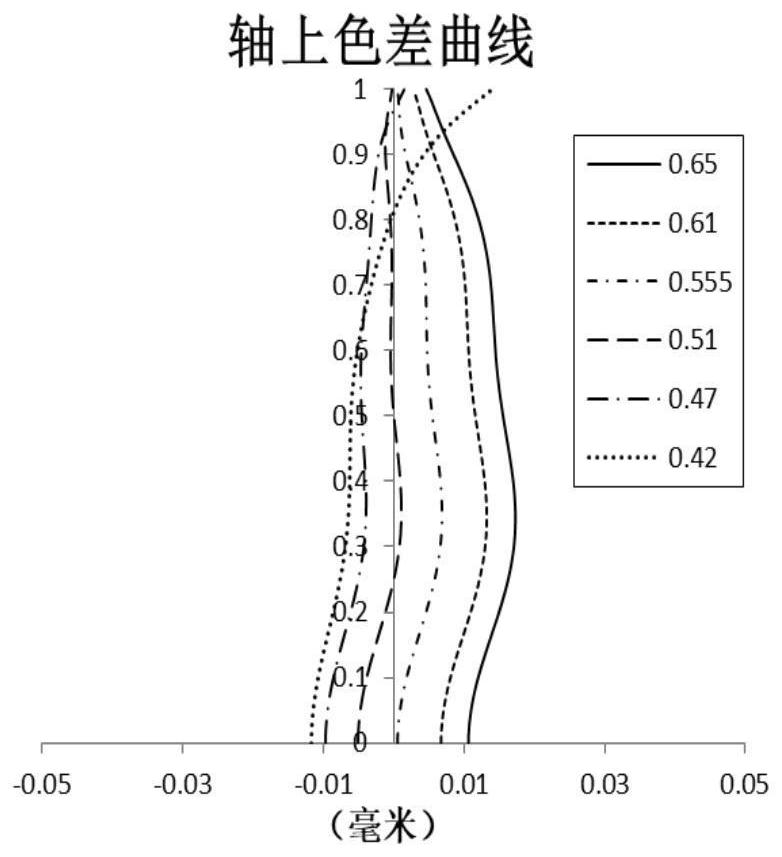

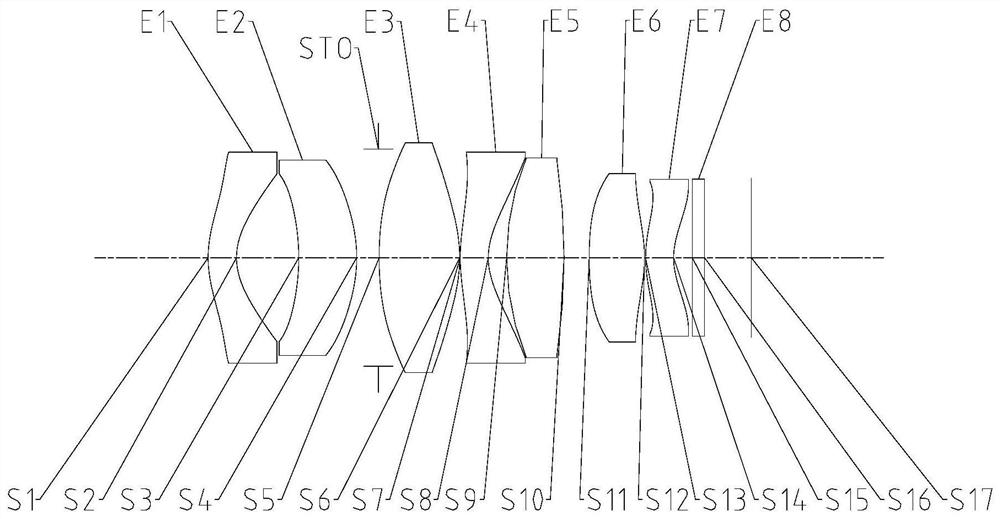

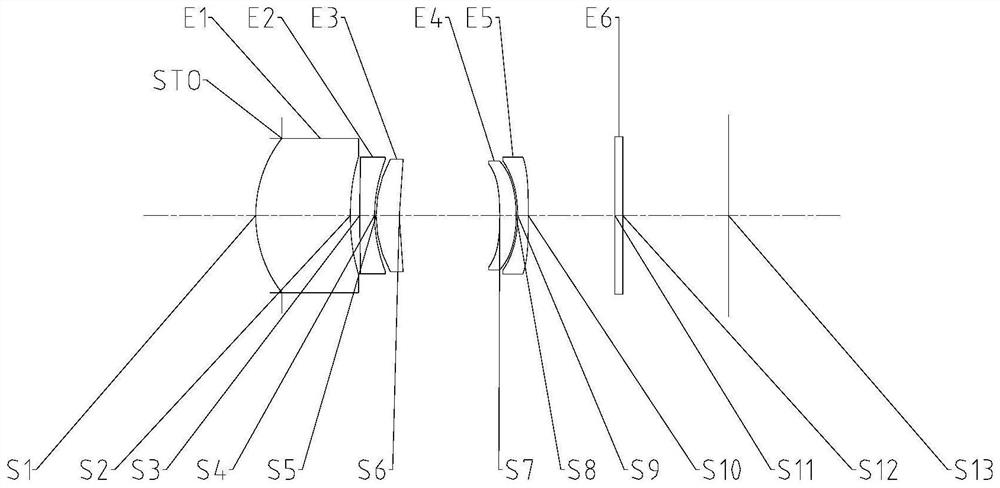

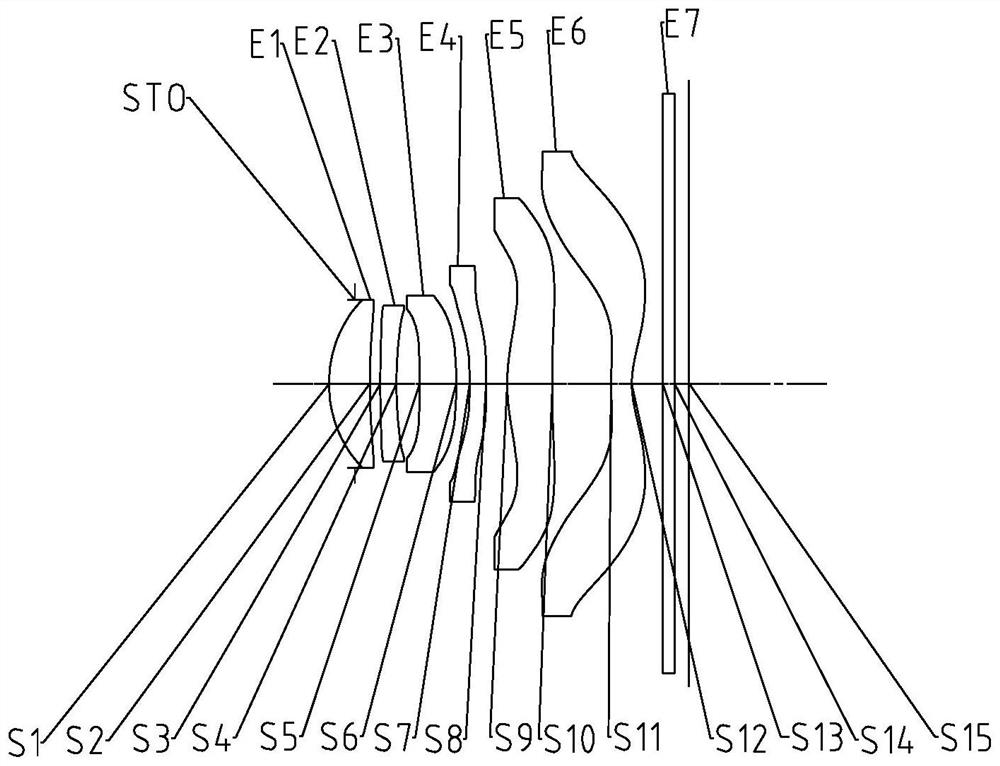

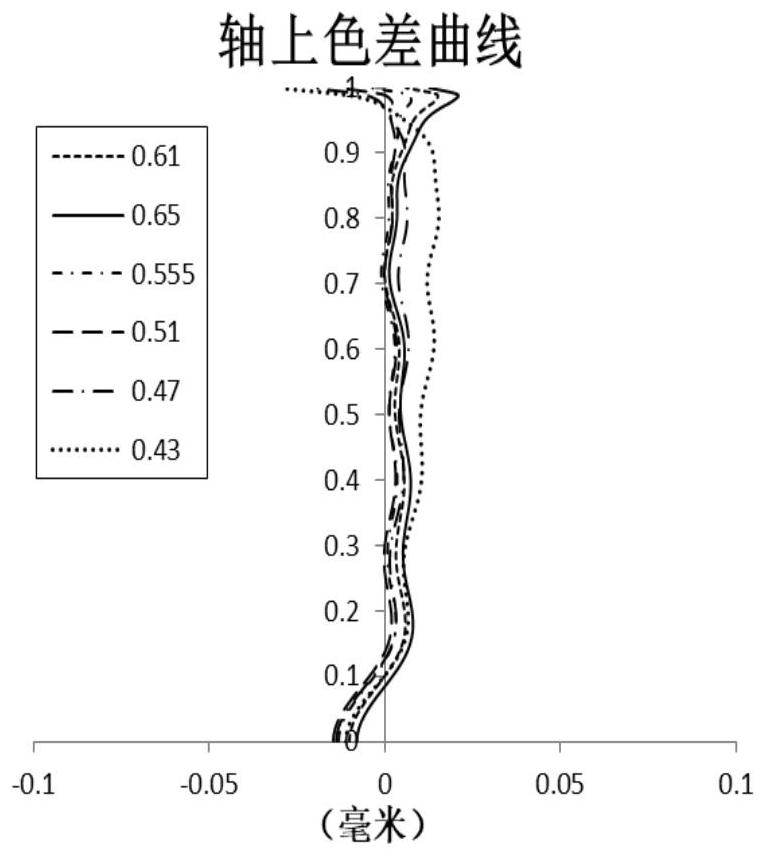

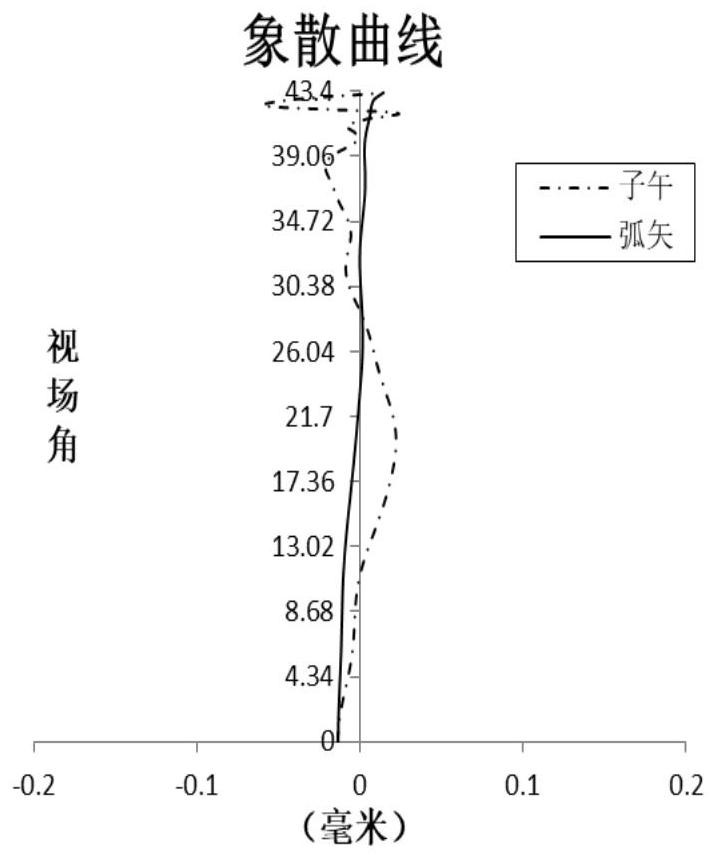

The invention discloses an optical imaging camera lens. The optical imaging camera lens comprises a first lens, a second lens, a third lens, a fourth lens, a fifth lens, a sixth lens, a seventh lens and an eighth lens along an optical axis in sequence from an object side to an image side. The first lens has positive focal power, wherein the object side face of the first lens is a convex face, andthe image side face of the first lens is a concave face. The second lens has negative focal power, wherein the image side face of the second lens is a concave face. The third lens has focal power, wherein the object side face of the third lens is a convex face, and the image side face of the third lens is a concave face. The fourth lens has focal power, the fifth lens has focal power, and the sixth lens has focal power. The seventh lens has positive focal power, wherein the object side face of the seventh lens is a convex face. The eighth lens has negative focal power, wherein the object sideface of the eighth lens is a concave face, and the image side face of the eighth lens is a concave face. The half length ImgH of the diagonal line of an effective pixel region on an imaging face of the optical imaging camera lens is larger than 5.80 mm, and the effective focal length f7 of the seventh lens and the total effective focal length f of the optical imaging camera lens meet the conditionthat f7 / f is larger than 1.00 and smaller than 2.00.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

Optical imaging lens

The application discloses an optical imaging lens. The optical imaging lens comprises a first optical lens with focal power; a second optical lens with positive optical power; a third lens with negative optical power; a fourth optical lens with optical power; a fifth optical lens with optical power; a sixth optical lens with optical power; a seventh lens with positive optical power; and an eighthlens with the negative optical power, wherein the first optical lens, the second optical lens, the third optical lens, the fourth optical lens, the fifth optical lens, the sixth optical lens, the seventh optical lens and the eight optical lens are arranged in order from an object side to an image side along an optical axis; the total effective focal length f of the optical imaging lens and the maximum field angle FOV of the optical imaging lens satisfy a formula that fxTAN (FOV / 2) is more 4.0mm, and a total effective focal length f of the optical imaging lens, a center thickness CT7 of the seventh optical lens on the optical axis, and the center thickness CT8 of the eighth optical lens on the optical axis satisfy the formula that f / (CT7+ CT8) is not less than 5.0.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

Optical imaging lens

The present application discloses an optical imaging lens. The optical imaging lens includes, in an order from an object side to an image side along an optical axis: a first lens having optical power;a second lens having optical power; a third lens having negative optical power; a fourth lens having optical power and whose object side is convex; a fifth lens having optical power and whose objectside is concave; a sixth lens having optical power; a seventh lens having optical power; and an eighth lens having optical power. The total effective focal length f of the optical imaging lens and themaximum half angle of view of the optical imaging lens Semi-FOV meet: fxtan(Semi-FOV)>5.5mm, and the total effective focal length f of the optical imaging lens and the effective focal length f1 of the first lens meet: 0.5<f / f1<1.5.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

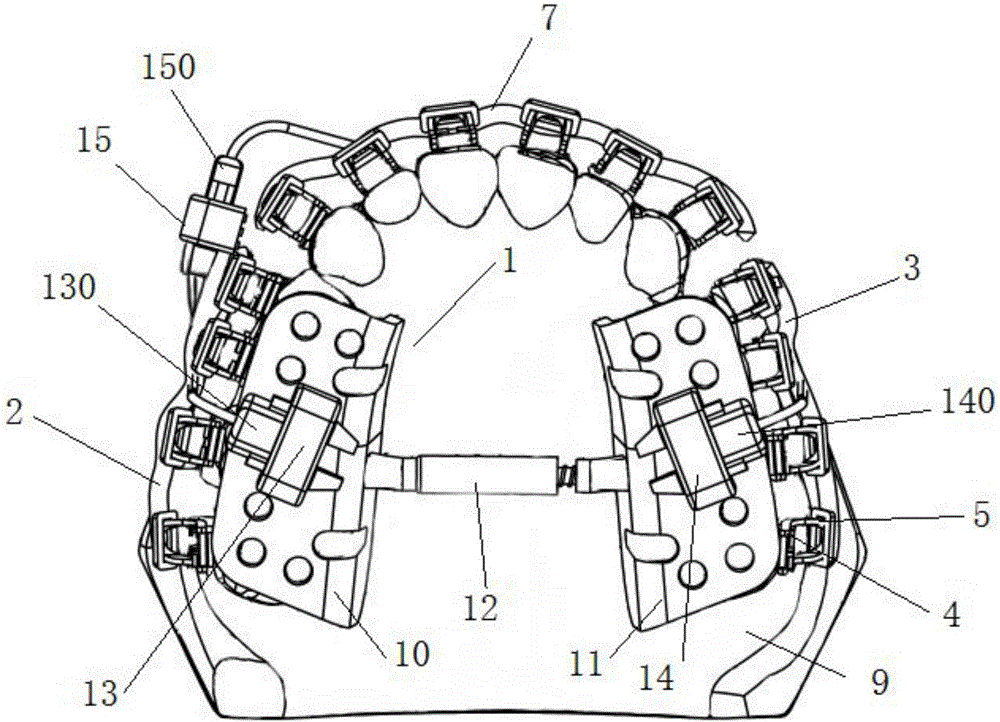

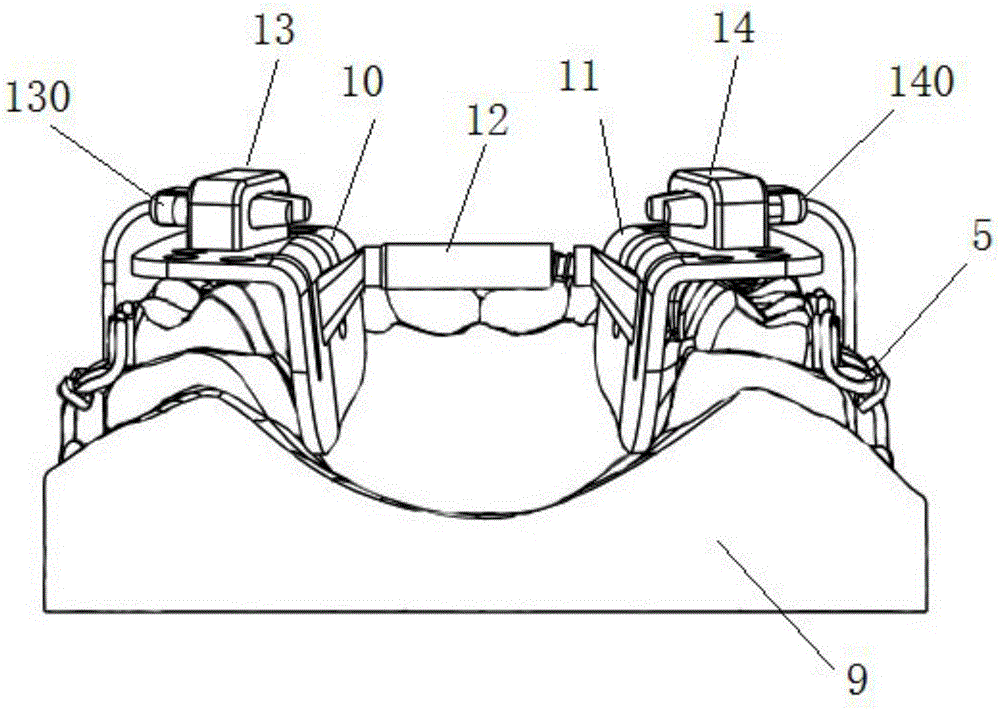

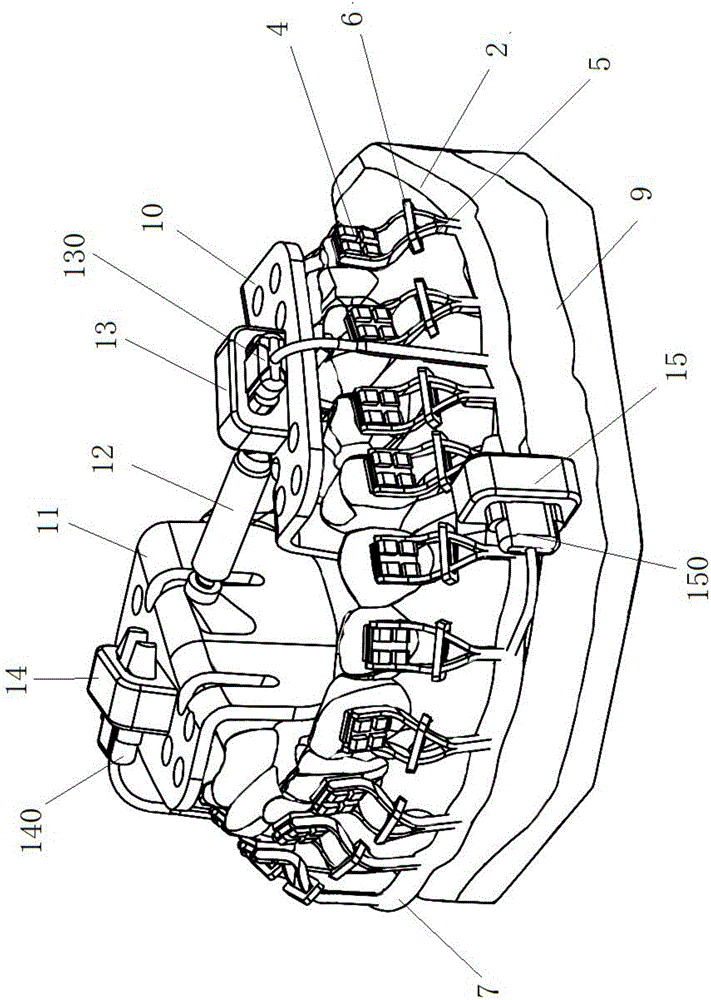

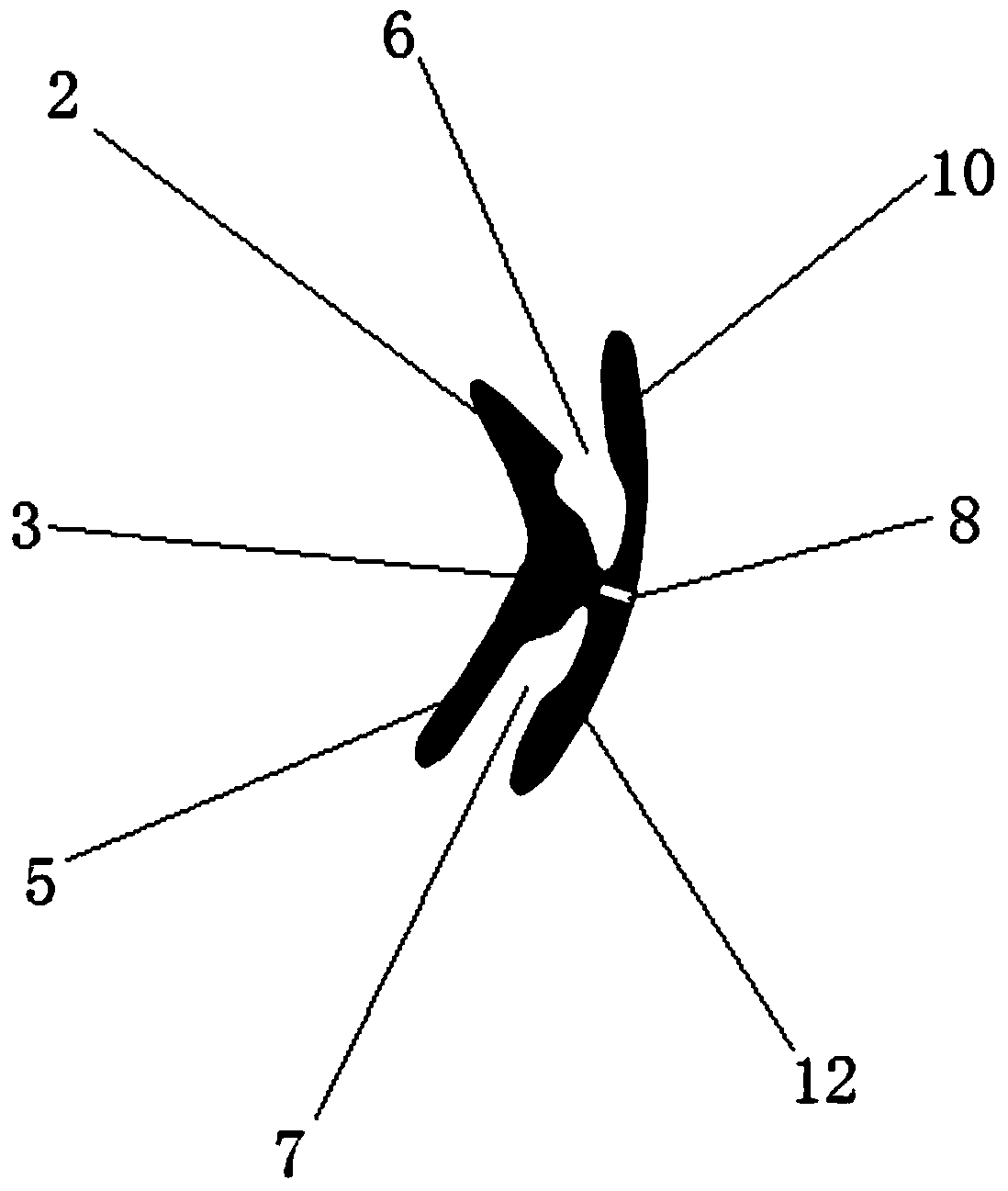

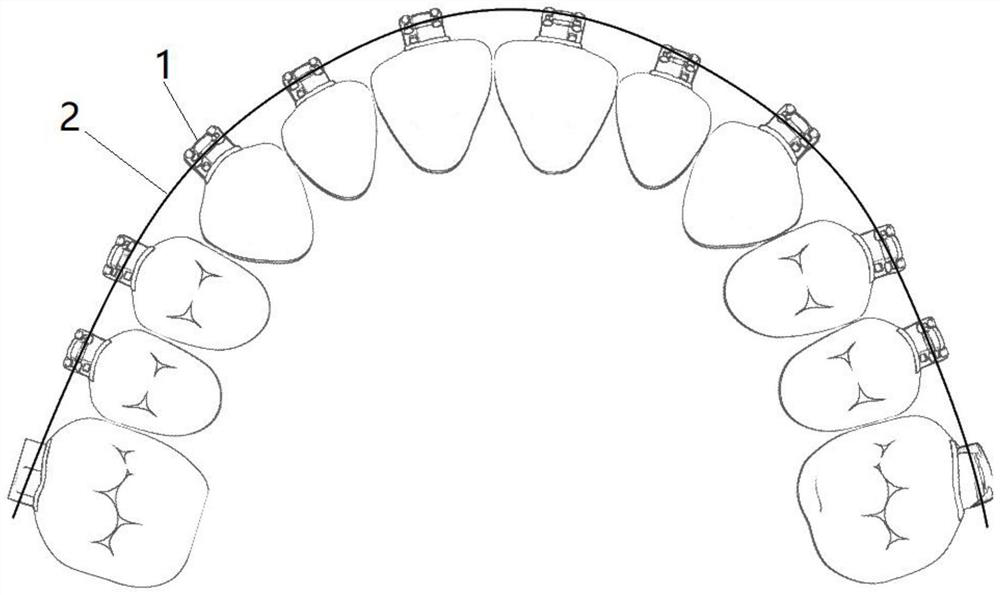

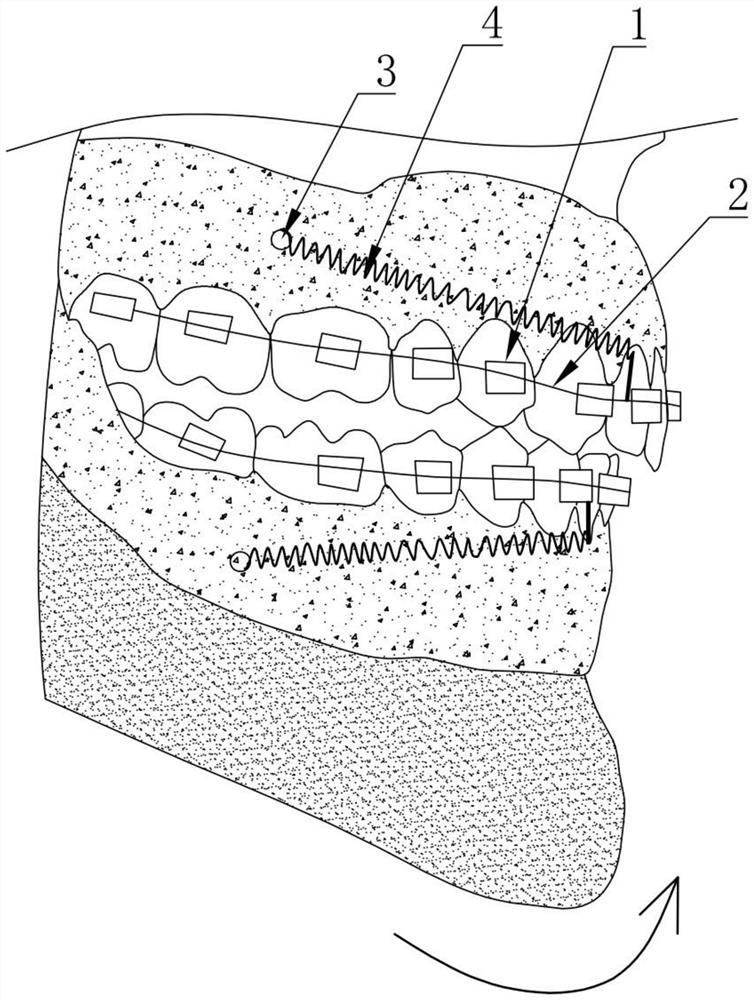

Orthodontic bracket indirect bonding precise positioning system and application method

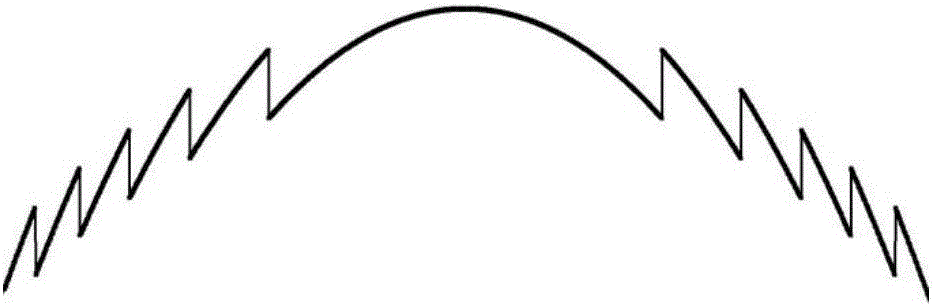

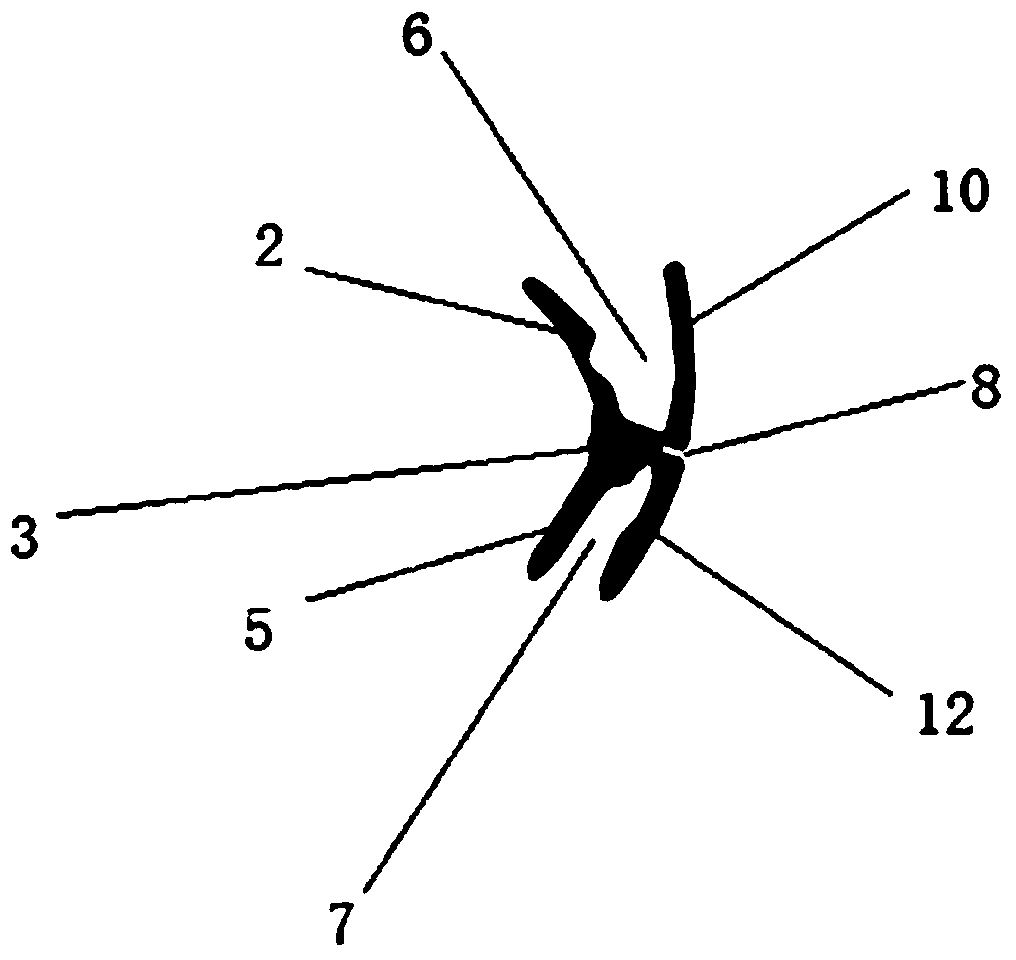

The invention relates to an orthodontic bracket indirect bonding precise positioning system and an application method. The orthodontic bracket indirect bonding precise positioning system comprises a local positioning tray (1), a rear right tooth transfer arch-shaped rod (2), a rear left tooth transfer arch-shaped rod (3) and a front tooth transfer arch-shaped rod (7). The local positioning tray (1) comprises a first single side positioning local tray body (10) and a second single side positioning local tray body (11) which are symmetrically arranged, and a detachable spring ejecting rod (12) is installed between the first single side positioning local tray body (10) and the second single side positioning local tray body (11). By means of the orthodontic bracket indirect bonding precise positioning system and the application method, a bracket can be more precisely arranged; the bonding time is shortened; a patient feels more comfortable, and an upper bracket for intraoral teeth can be easily and quickly bonded clinically. In addition, healthier human engineering is achieved through indirect bonding, three-dimensional control over the teeth can be conveniently achieved, facial form improvement can be better achieved, and a good correction effect can be obtained.

Owner:赵计林

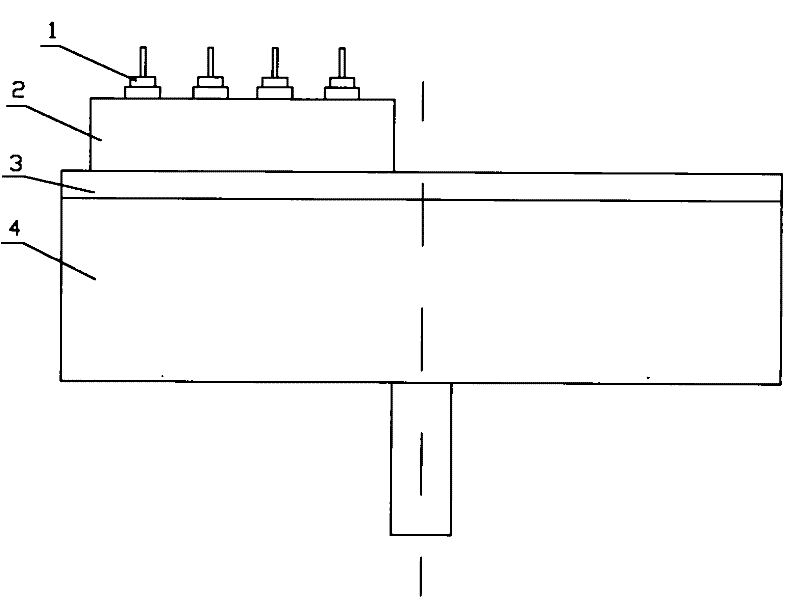

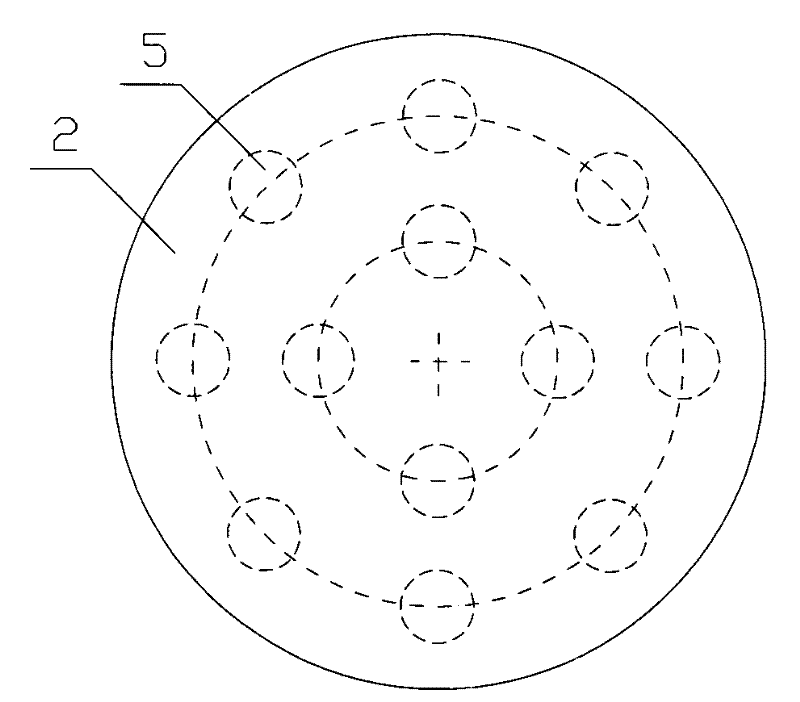

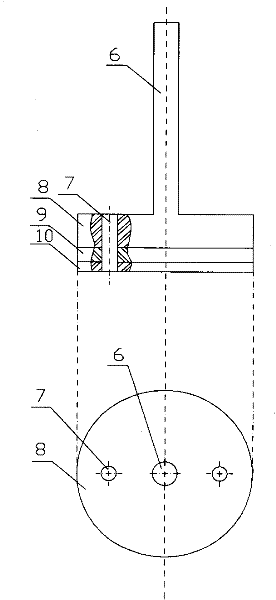

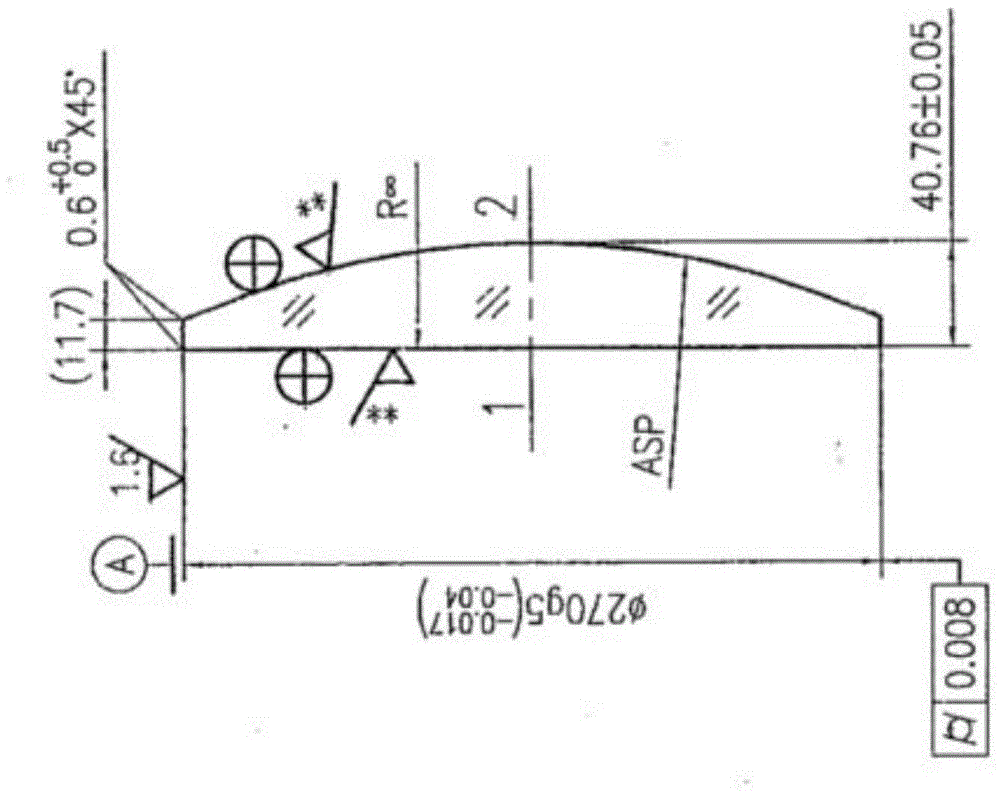

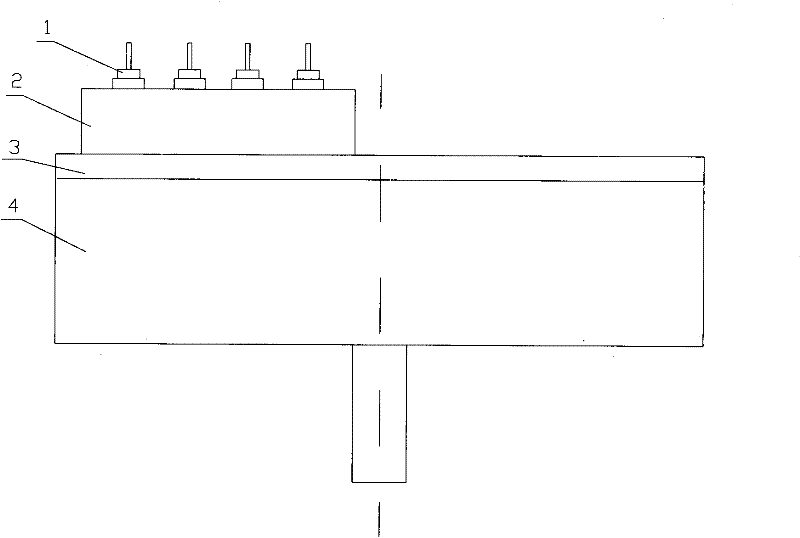

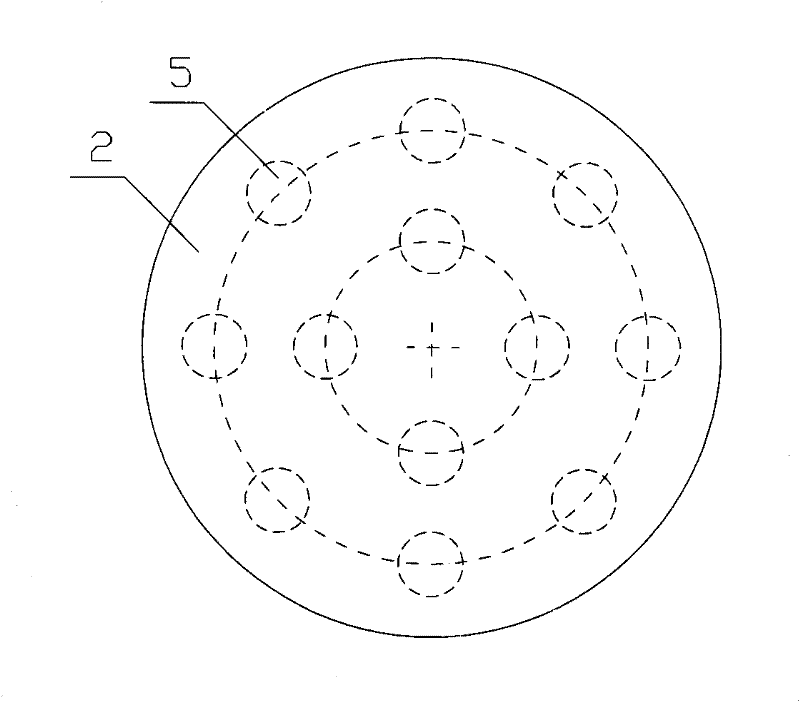

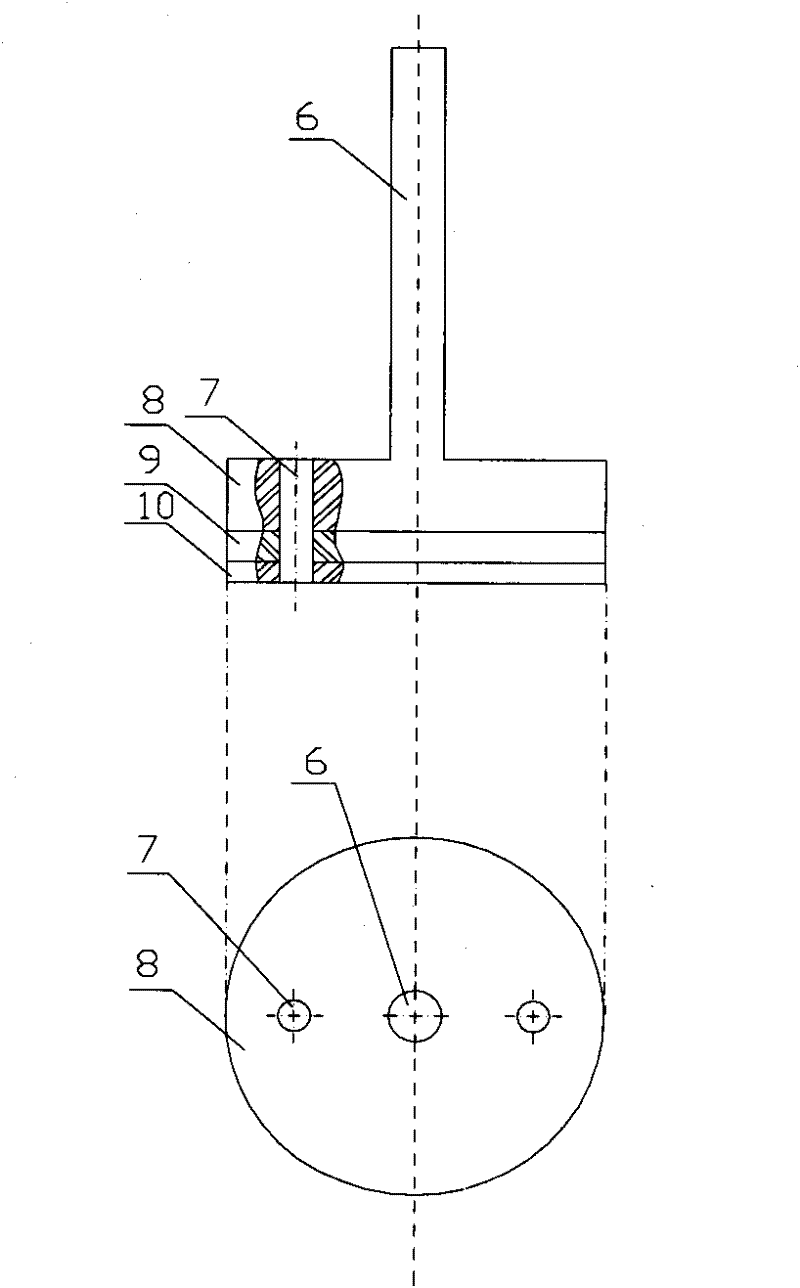

Adjustable pressure device used for polishing heavy-calibre plane optical element

InactiveCN102049716AOvercome the disadvantage of uncontrollable pressureImprove facial shapeOptical surface grinding machinesEngineeringMechanical engineering

The invention provides an adjustable pressure device used for polishing a heavy-calibre plane optical element, relating to a pressure device. The adjustable pressure device used for polishing the heavy-calibre plane optical element, provided by the invention, is used for regulating the pressure intensity born by a polishing surface of a workpiece when being processed, is capable of improving the polishing quality of the workpiece and controlling the removal rate of materials, and has simple and practical structure. The adjustable pressure device is provided with a mass block and a fixture flat plate, wherein the mass block is used as a pressure source; the fixture flat plate is provided with a fulcrum bar, a base and an adsorption base film, the fulcrum bar is used for loading the mass block, the lower part of the base is connected with the adsorption base film, a base body and a film are arranged on the adsorption base film, the base is adsorbed on the surface of the workpiece through the film of the adsorption base film to ensure that the whole device is fixed on the corresponding part of the workpiece.

Owner:XIAMEN UNIV

Rapid environment-friendly double-sided polishing method for silicon wafer substrate

ActiveCN112908834AImprove polishing efficiencyReduce manufacturing costSemiconductor/solid-state device manufacturingCerium oxideUltra precision

The invention relates to the technical field of ultra-precision machining of semiconductors, in particular to a rapid environment-friendly double-sided polishing method for a silicon wafer substrate. The rapid environment-friendly double-sided polishing method for a silicon wafer substrate comprises the following steps: (1) rough polishing: carrying out chemical mechanical polishing on a silicon wafer substrate by using a rough polishing solution, wherein the rough polishing solution is prepared from cerium oxide, deionized water, a dispersing agent and a pH adjusting agent; (2) fine polishing: carrying out chemical mechanical polishing on the silicon wafer substrate subjected to rough polishing by using a fine polishing solution, wherein the fine polishing solution is prepared from cerium oxide, deionized water and a dispersing agent. According to the polishing method, a two-step chemical mechanical polishing method is adopted, cerium oxide polishing solutions with different particle sizes, different polishing pads and different pH conditions are adopted, the pressure of a polishing disc and the rotation speed ratio of a center gear are controlled, the polishing efficiency of the silicon wafer substrate can be effectively improved, the average thickness difference of the polished substrate is small, and the bending warping degree is low.

Owner:广西立之亿新材料有限公司

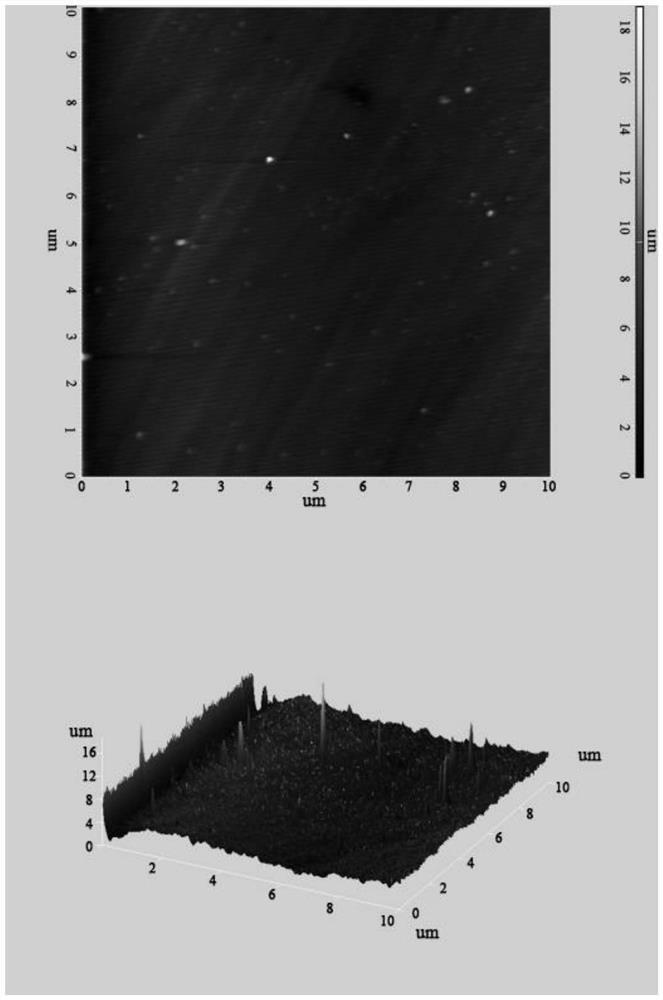

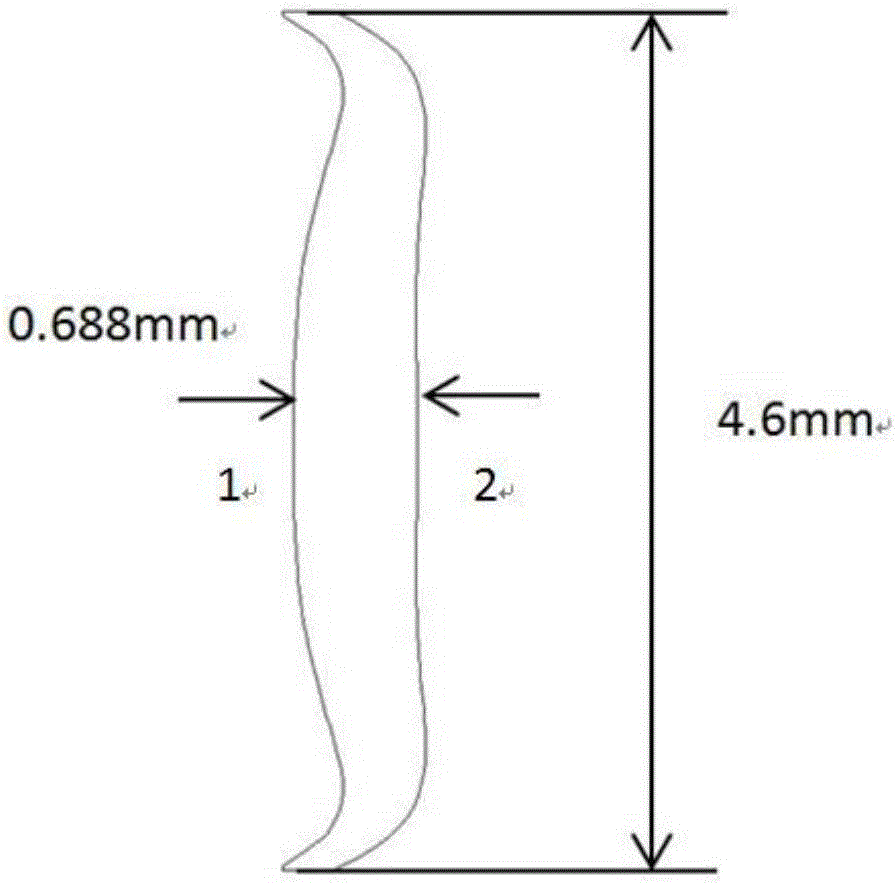

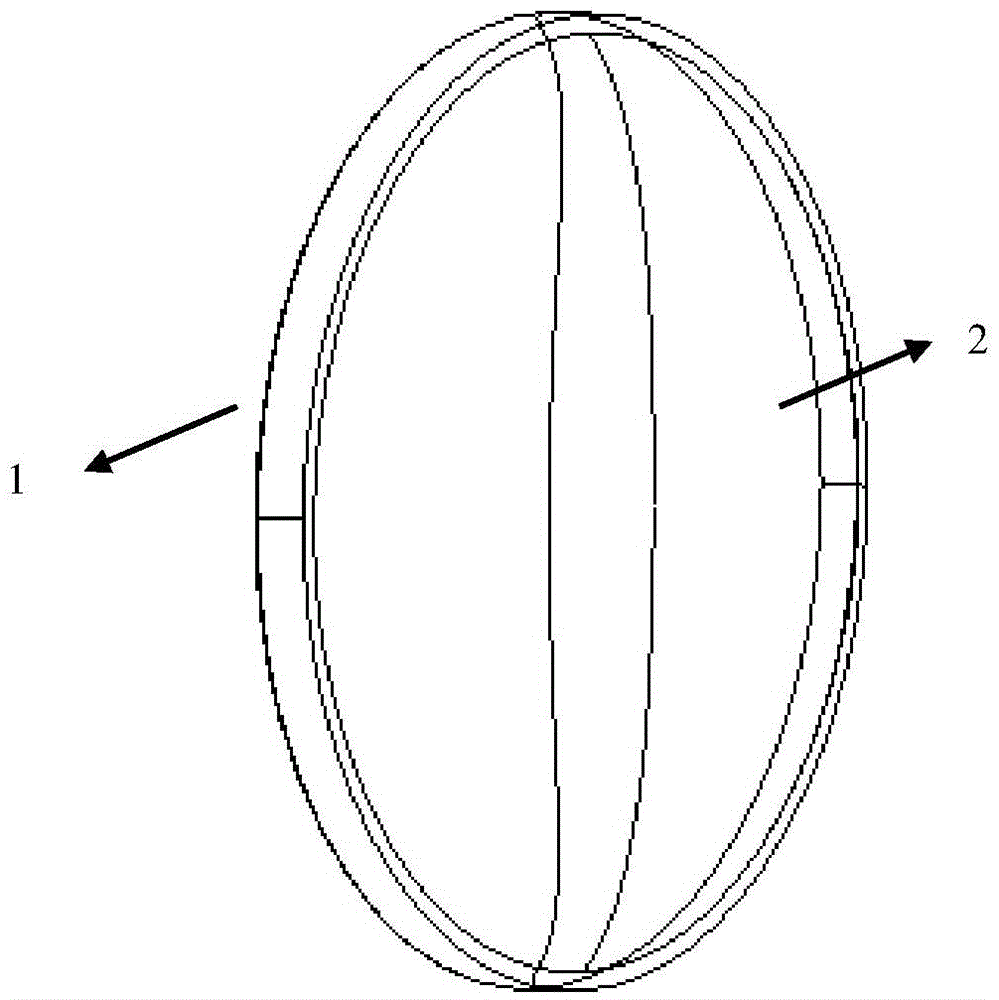

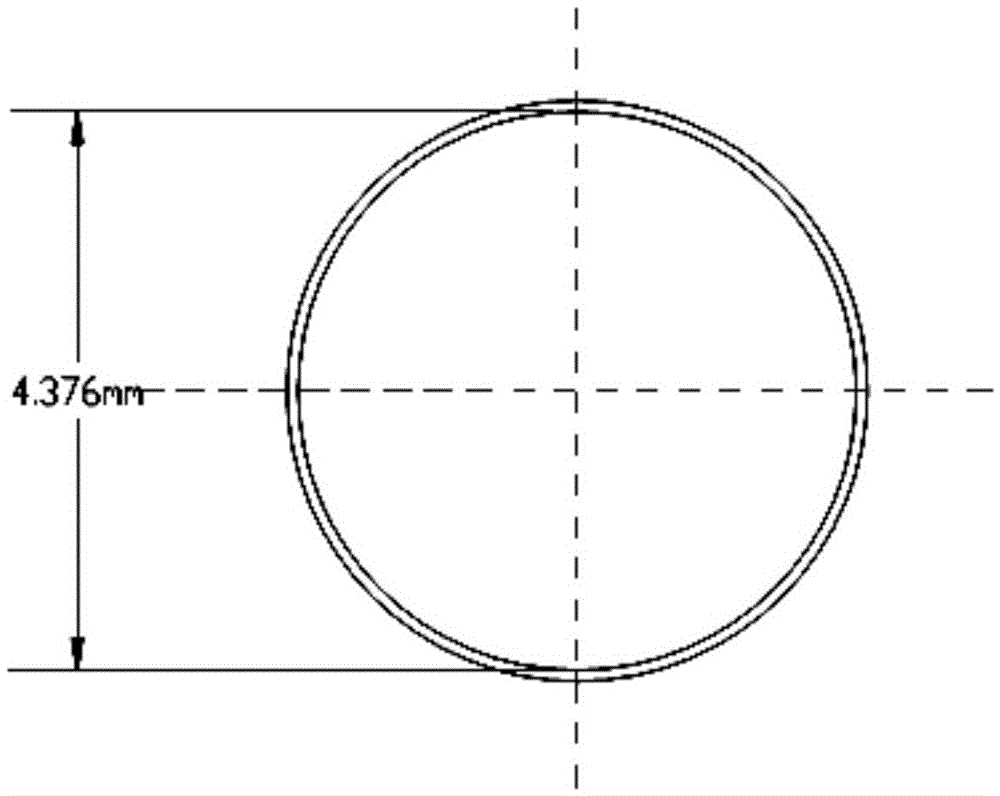

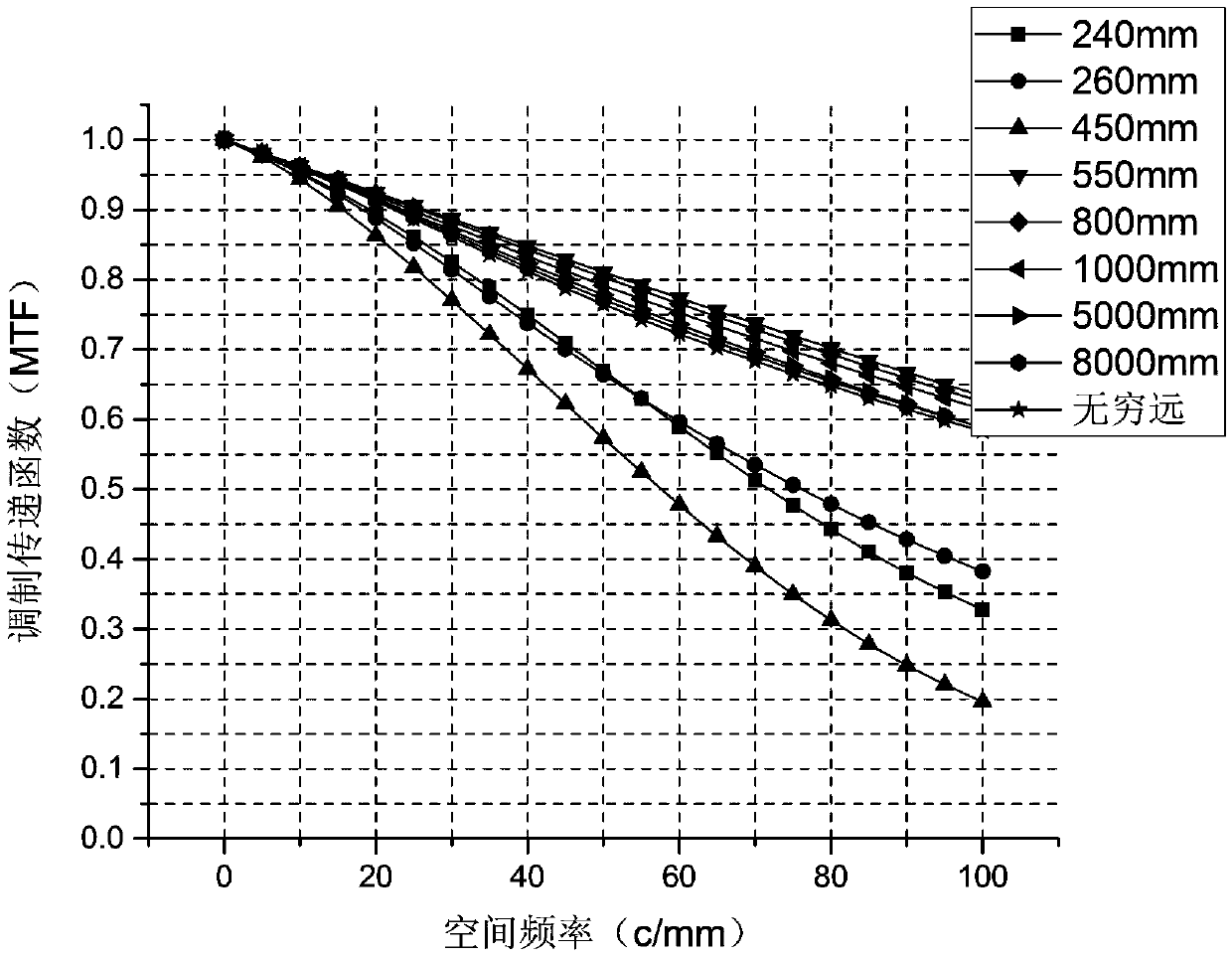

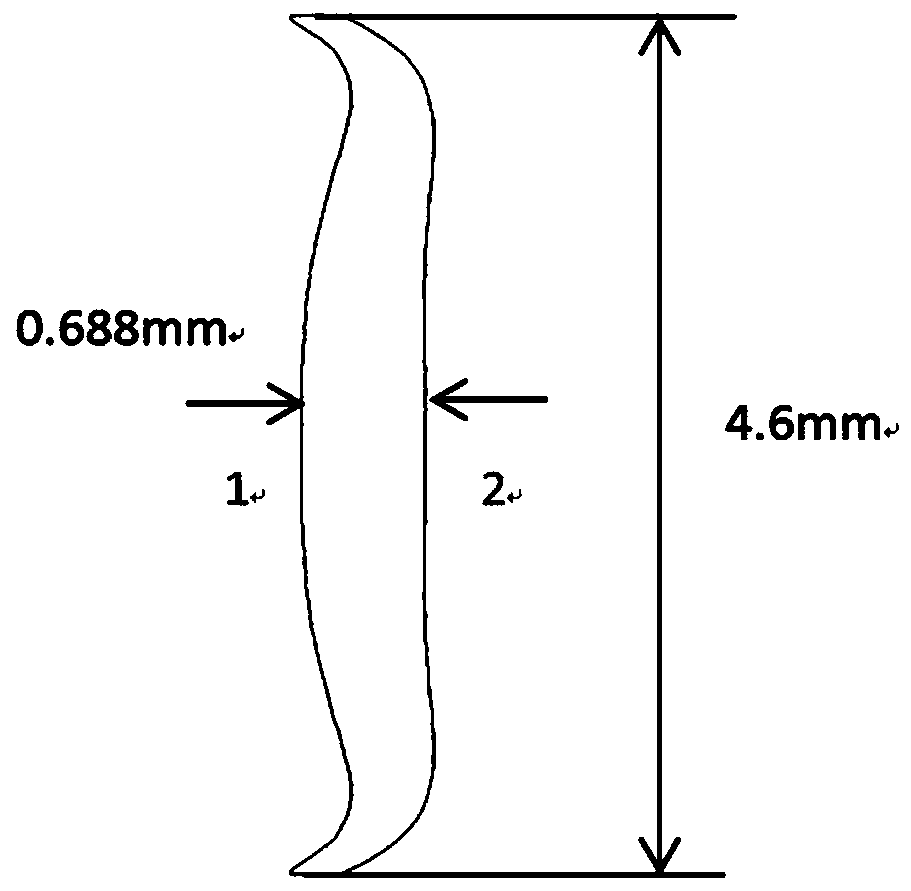

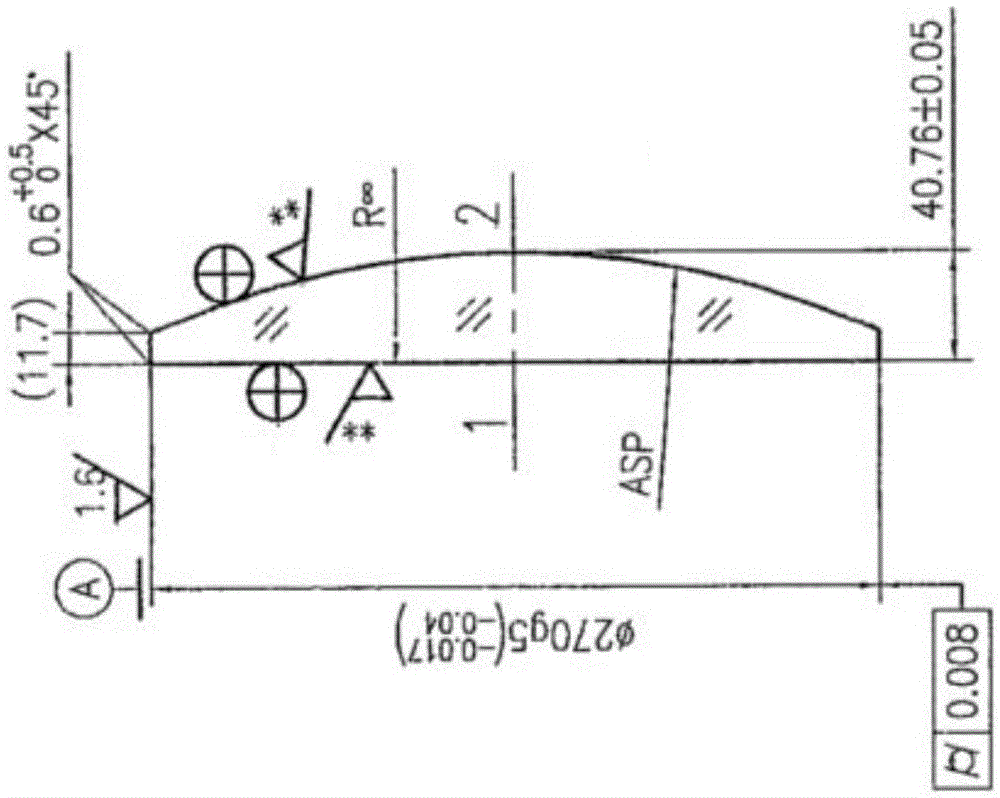

Big coke focal sphere diffractive artificial lens

ActiveCN106491244AImprove facial shapeLarge depth of field performanceIntraocular lensPresbyopiaPhysics

Big coke focal sphere diffractive artificial lens, is an artificial lens for replacing presbyopia eye natural crystal and for rectifying presbyopia eye. The artificial lens is prepared from polymethyl methacrylate material. the front and back surfaces of the artificial lens are twin convex aspherical surfaces symmetrical along the axial direction, the degree of diopter is 22D, the diameter of the optics department is 4.6mm, the back surface has a diffraction ring providing additional light focal power. The artificial lens has large depth of focus performance, planting the artificial lens eye model, can form images clearly at successive distances of 400mm to 5000mm.

Owner:NANKAI UNIV

Optical imaging lens

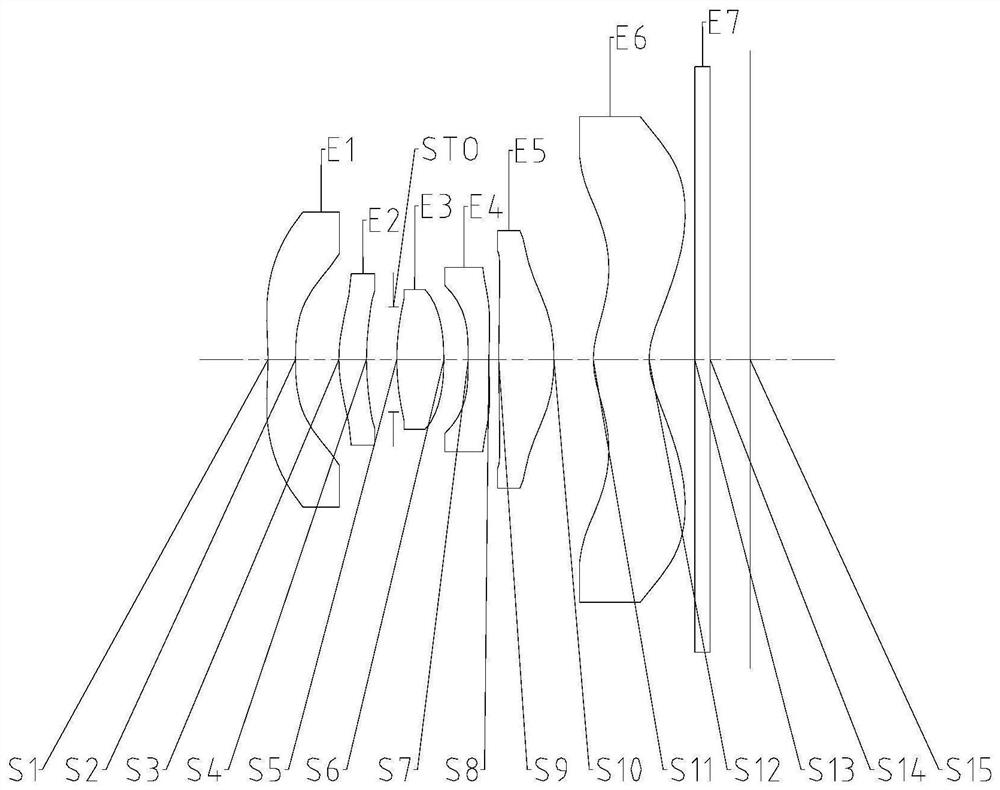

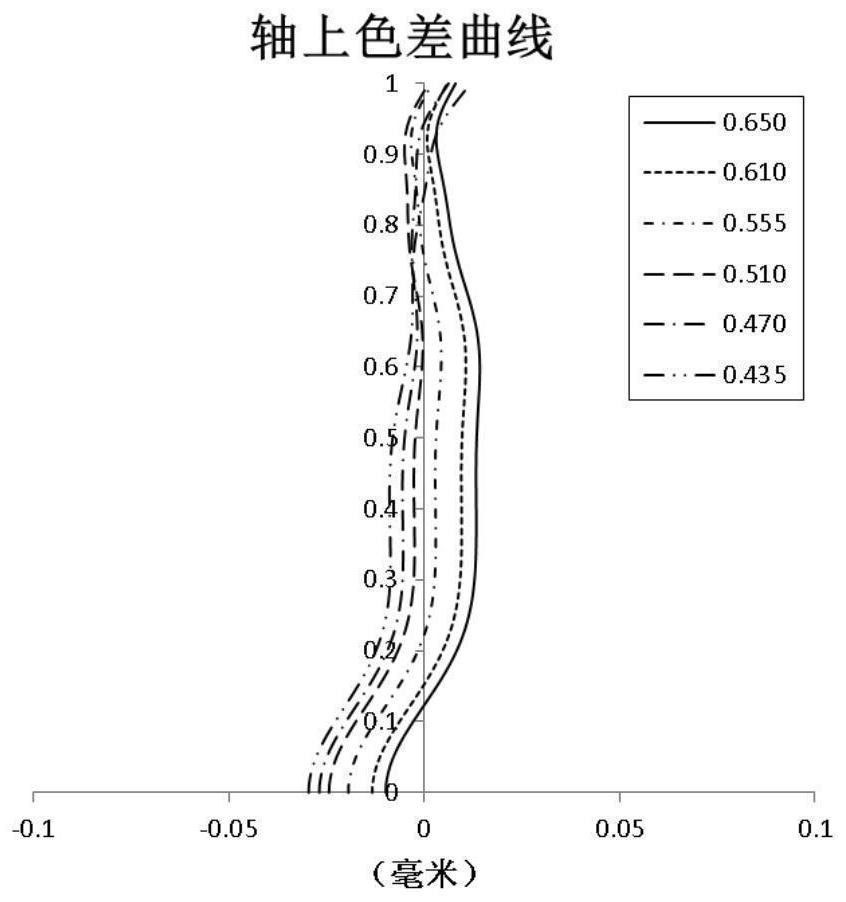

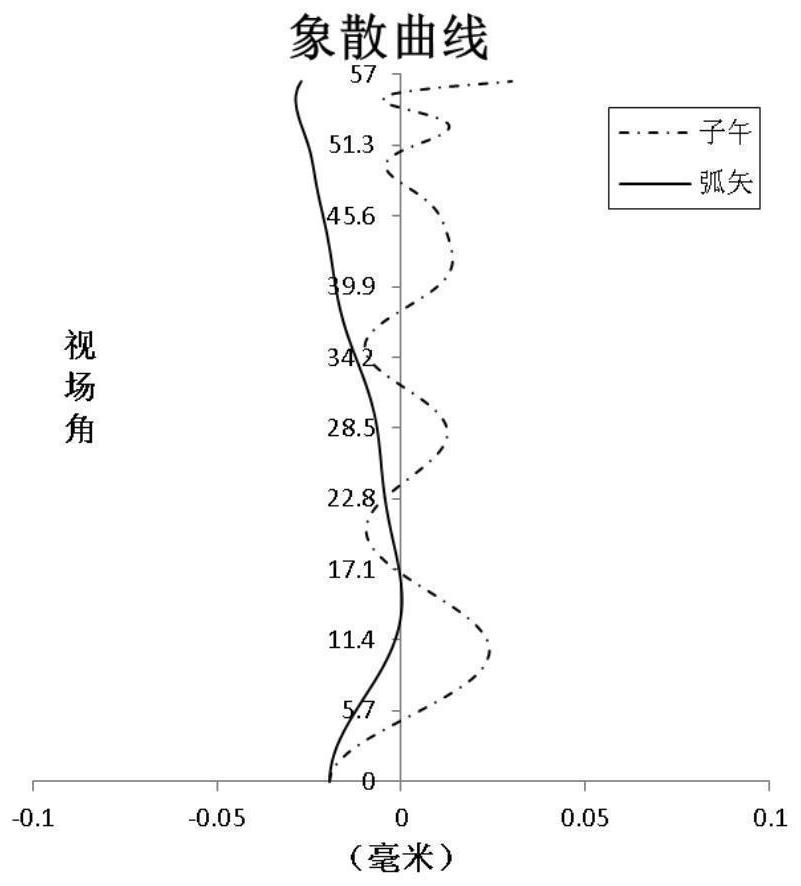

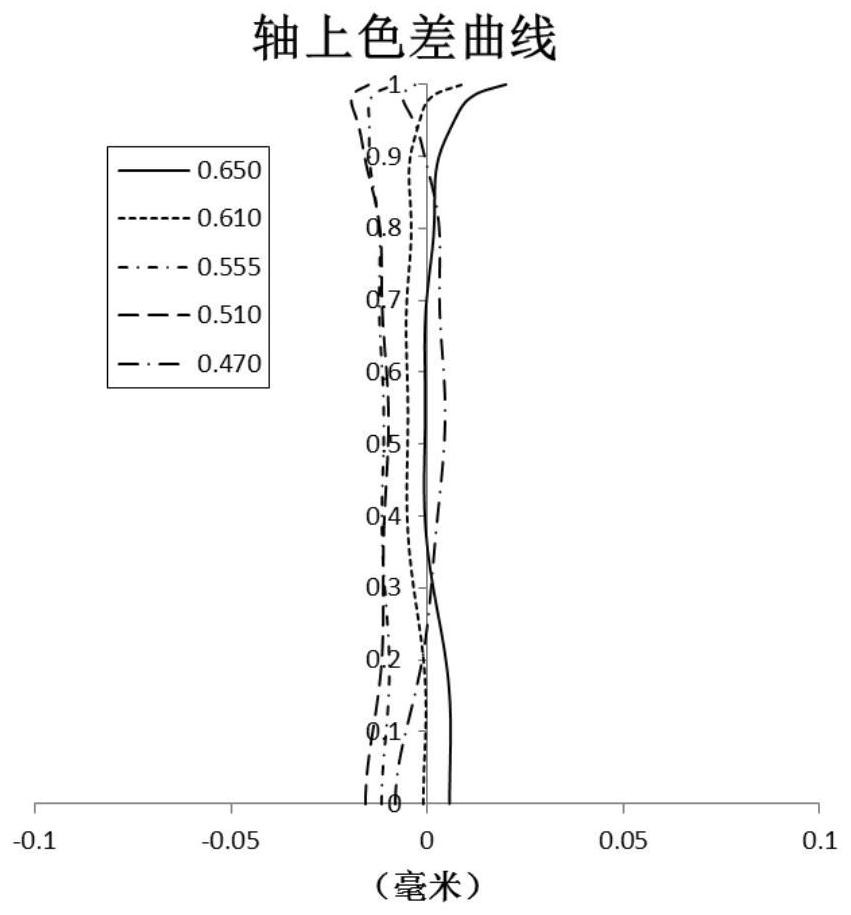

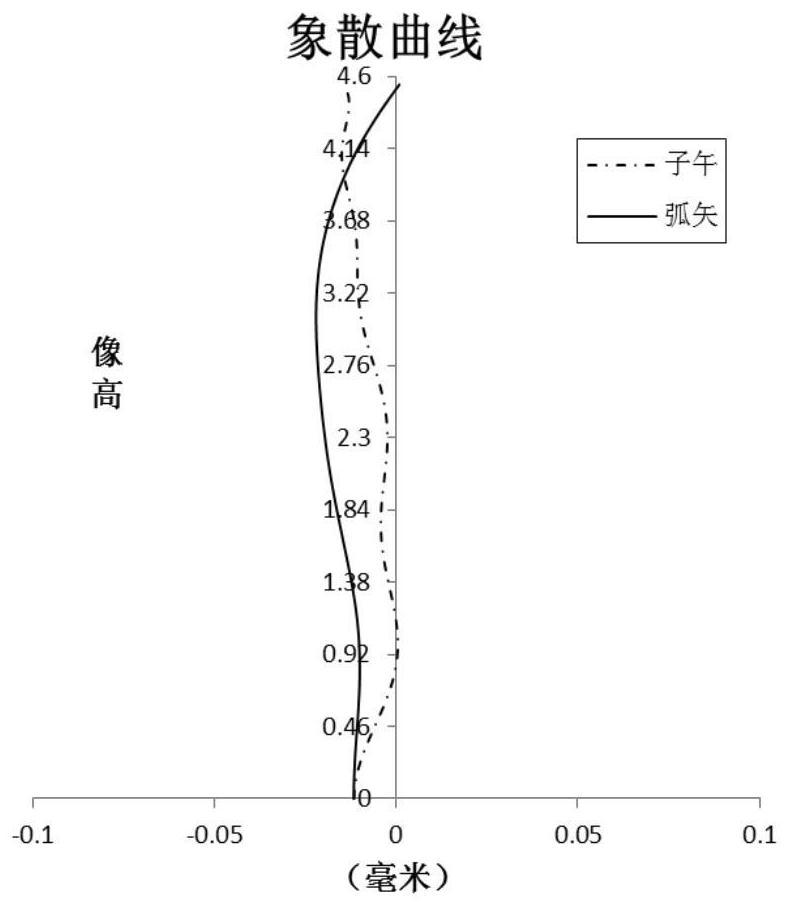

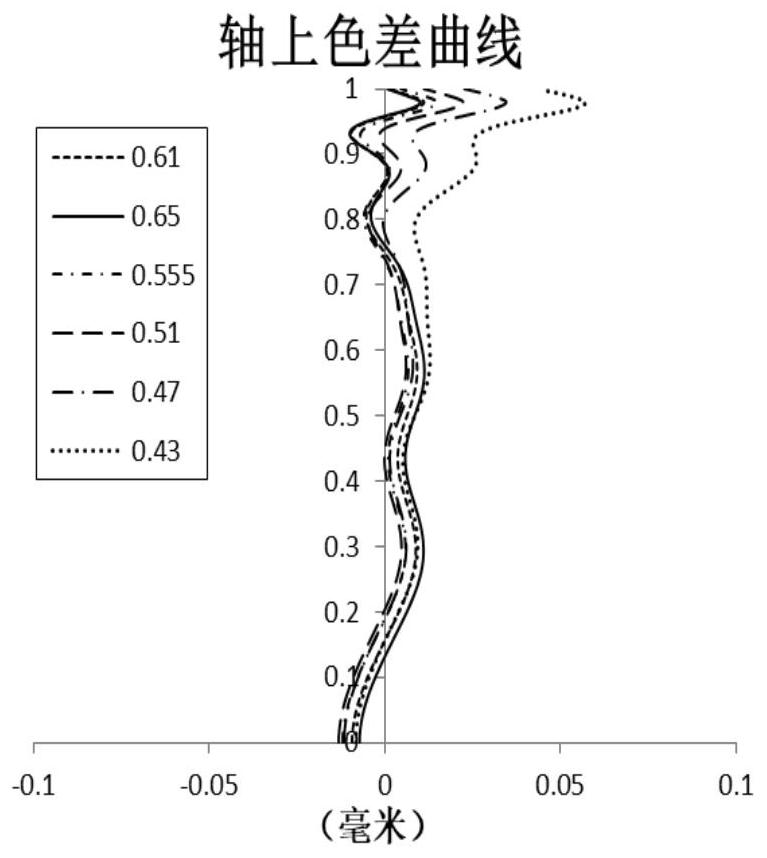

PendingCN110609375AWith telephoto characteristicsImprove image qualityOptical elementsCamera lensOptical axis

The application discloses an optical imaging lens comprising, in order from the object side to the image side along the optical axis, a first lens having a positive focal power, a second lens having anegative focal power, a third lens having a focal power, a fourth lens having a focal power and having an image side as a convex surface, and a fifth lens having a negative focal power and having anobject side as a concave surface, wherein a total effective focal length f of the optical imaging lens satisfies that f is greater than 12mm and less than 20mm.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

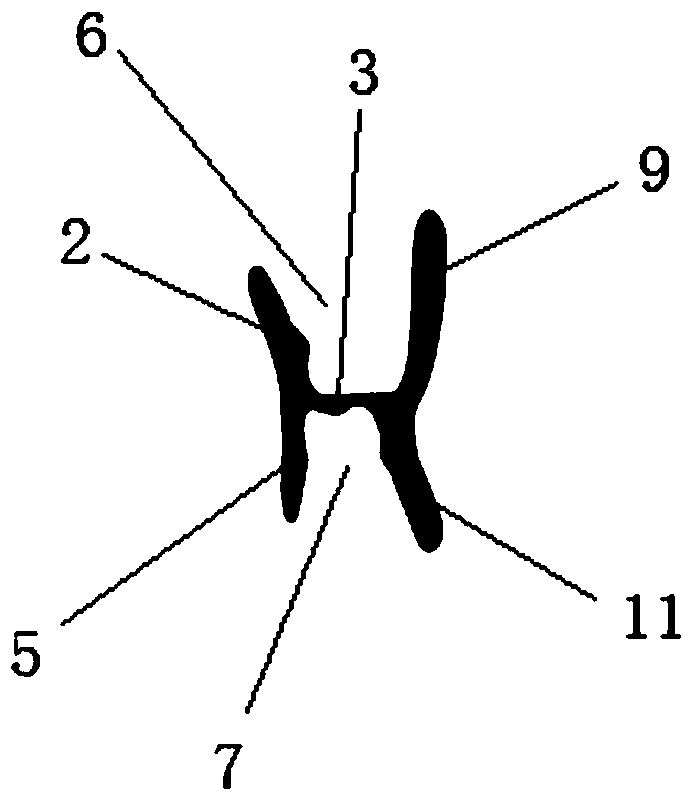

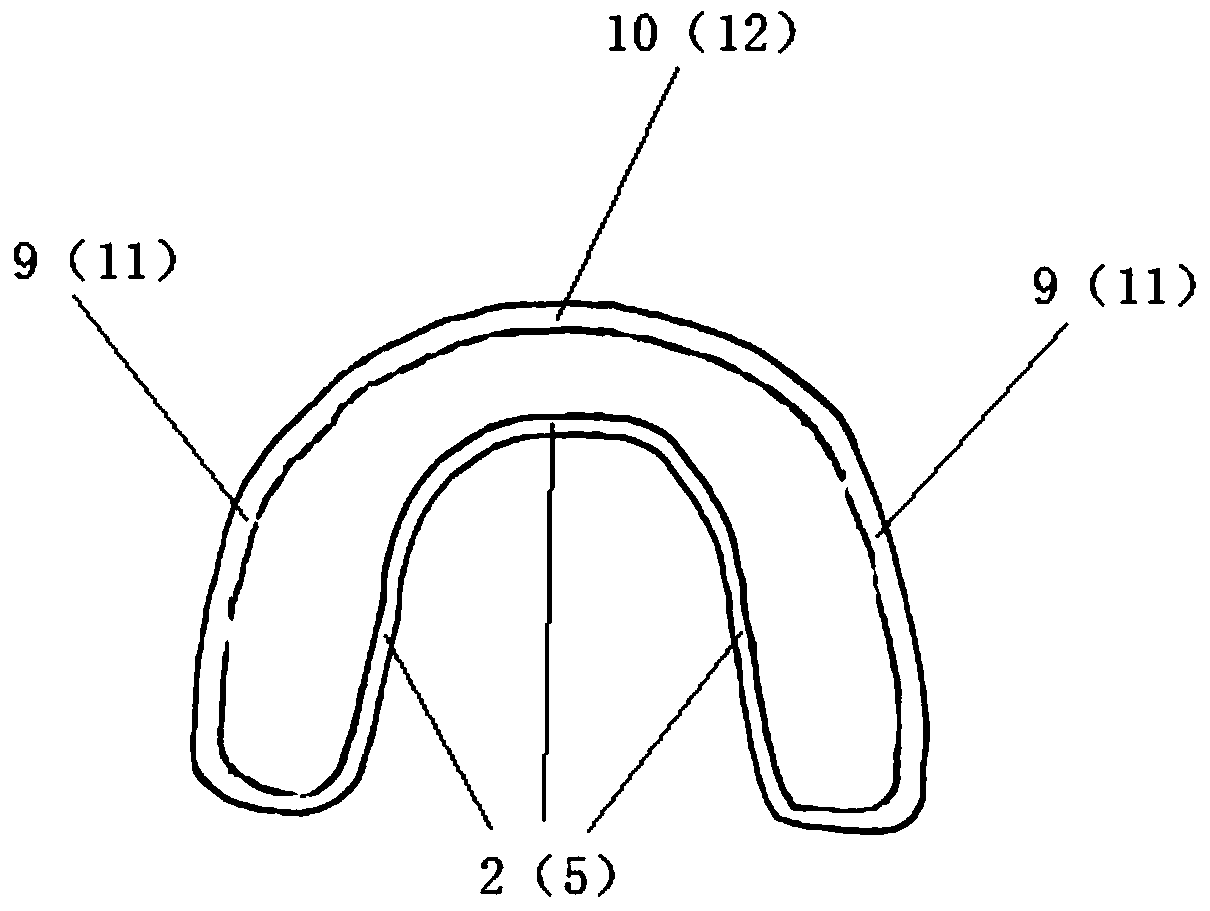

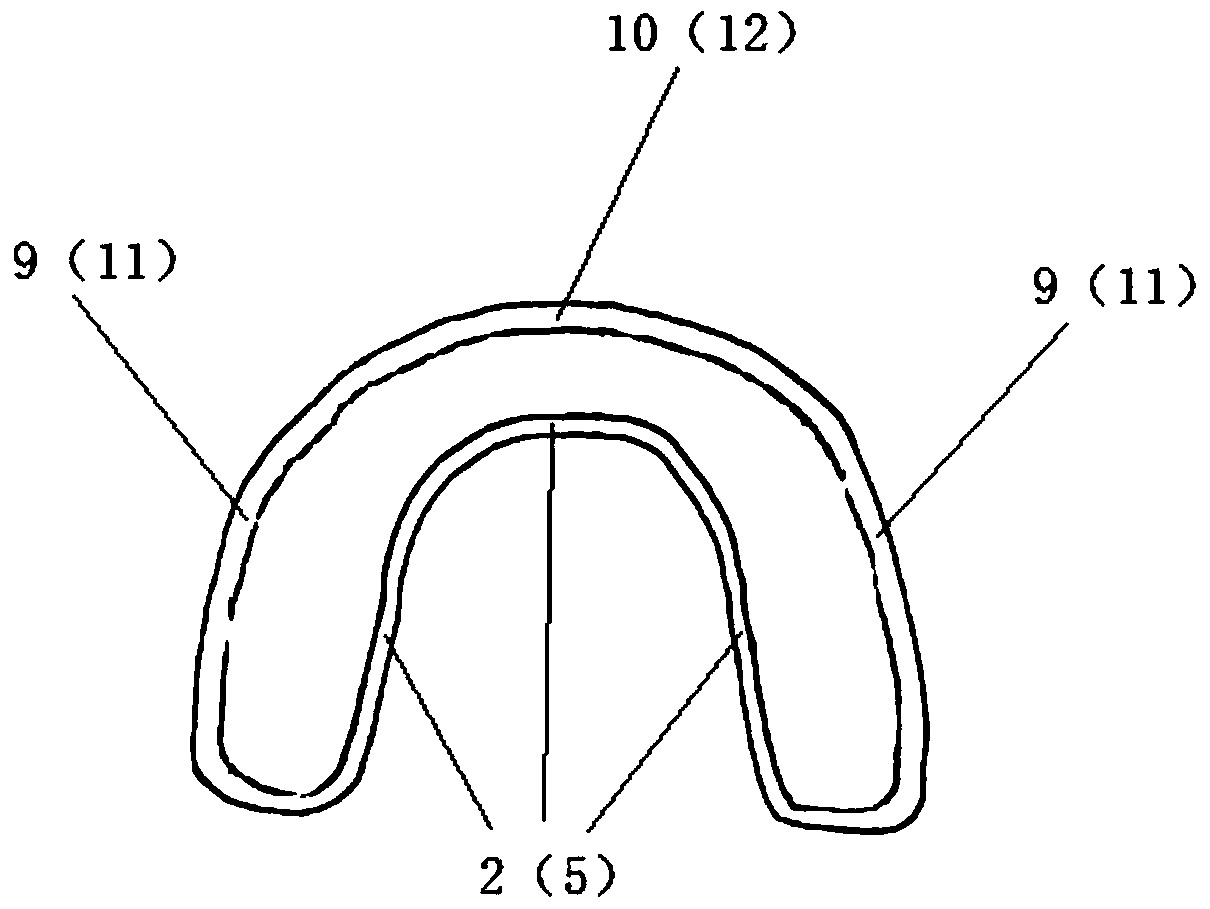

A type III personalized functional appliance

The invention discloses an III type appliance with a personalized function as well as a manufacture method and an application of the III type appliance. The III type appliance with the personalized function comprises a maxillary outer side base 1, a maxillary tongue side base 2, an occlusal pad 3, a mandible outer side base 4 and a mandible tongue side base 5, wherein the maxillary outer side base 1 and the maxillary tongue side base 2 are integrally connected through the occlusal pad 3 to form an upper tooth space 6, and the mandible outer side base 4 and the mandible tongue side base 5 are integrally connected through the occlusal pad 3 to form a lower tooth space 7. The III type appliance with the personalized function can promote growth of maxilla and inhibit growth of mandible, and the purpose of preventive or interruptive correction of functional III type malocclusion or mild bony III type malocclusion is achieved; correction is completed under the condition that tooth extraction for subtrahend is not adopted, the conditions that the front section of the upper dental arch becomes narrower and the side face of the upper dental arch is more umbilicate can be avoided, reverse occlusion of anterior teeth can be corrected, space is regained, dentition is aligned, the face shape is improved, and the III type appliance with the personalized function has a good application prospect.

Owner:STOMATOLOGY AFFILIATED STOMATOLOGY HOSPITAL OF GUANGZHOU MEDICAL UNIV

Optical imaging lens

The invention discloses an optical imaging lens, which sequentially comprises a first lens with negative focal power, a second lens with focal power, a third lens with focal power, a fourth lens with focal power, a fifth lens having focal power, and a sixth lens having focal power from an object side to an image side along an optical axis. The object side surface and the image side surface of the first lens are a concave surface. The image side surface of the fifth lens is a convex surface. The maximum field angle FOV of the optical imaging lens is greater than 100 degrees and less than 140 degrees. The absolute value of TV distortion TVD of the optical imaging lens is less than 1.1%. The half ImgH of the diagonal line length of an effective pixel area on the imaging surface of the optical imaging lens and the distance TTL from the object side surface of the first lens to the imaging surface along the optical axis meet the condition that ImgH / TTL is larger than 0.3 and smaller than 1.3.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

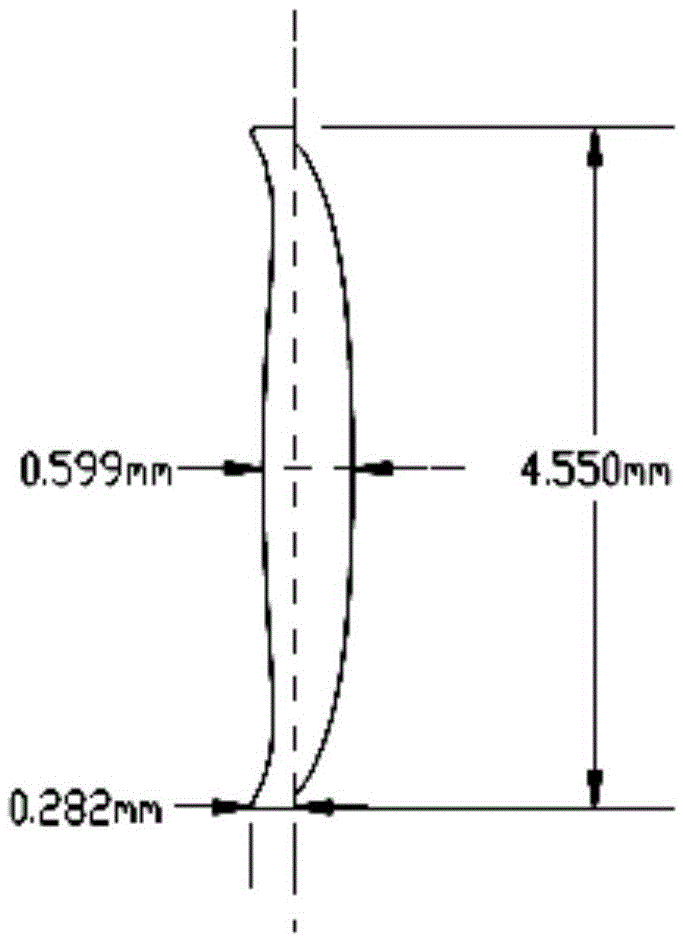

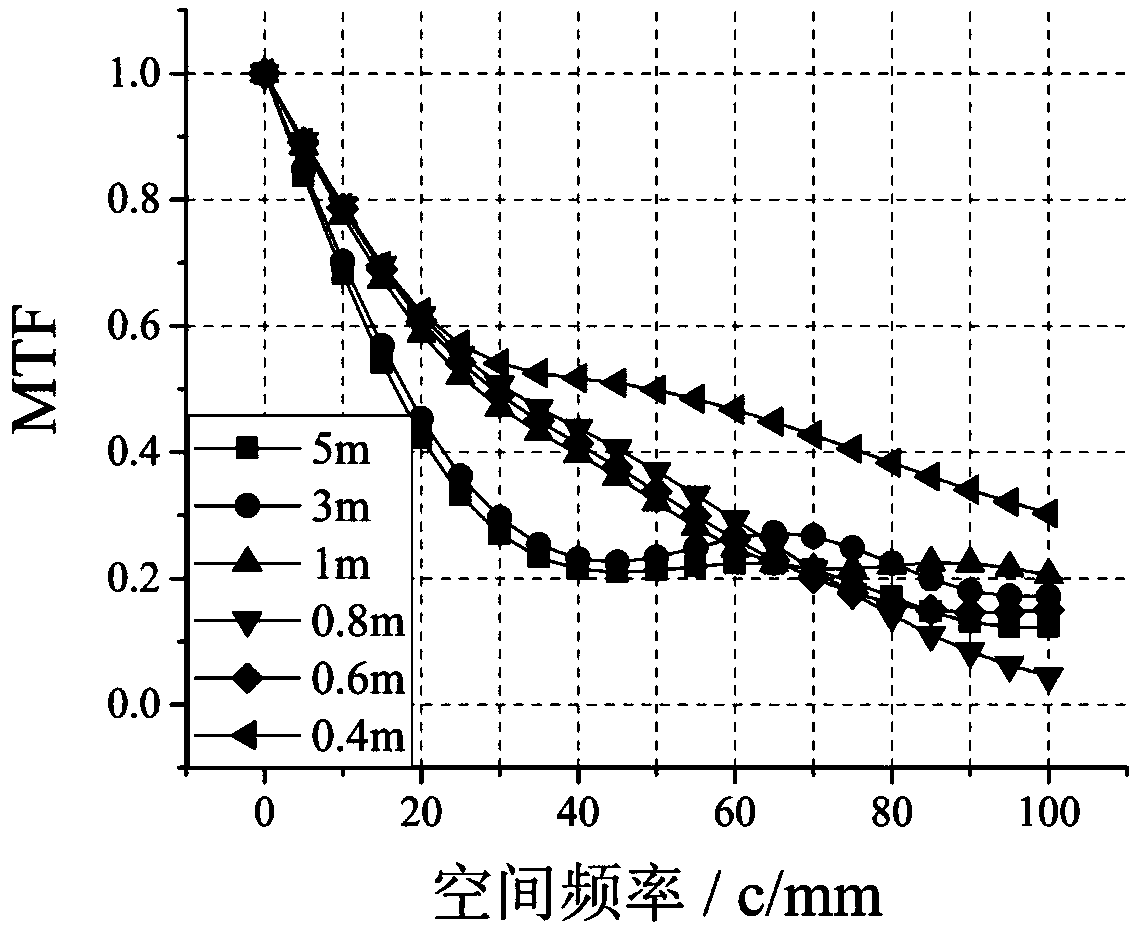

Intraocular lens with large depth of focus based on the residual accommodation of the human eye

ActiveCN104849782BImprove facial shapeIncrease contrast sensitivityIntraocular lensLensIntraocular lensPolymethyl methacrylate

Owner:TIANJIN SHI JI KANG TAI BIOMEDICAL ENG CO LTD

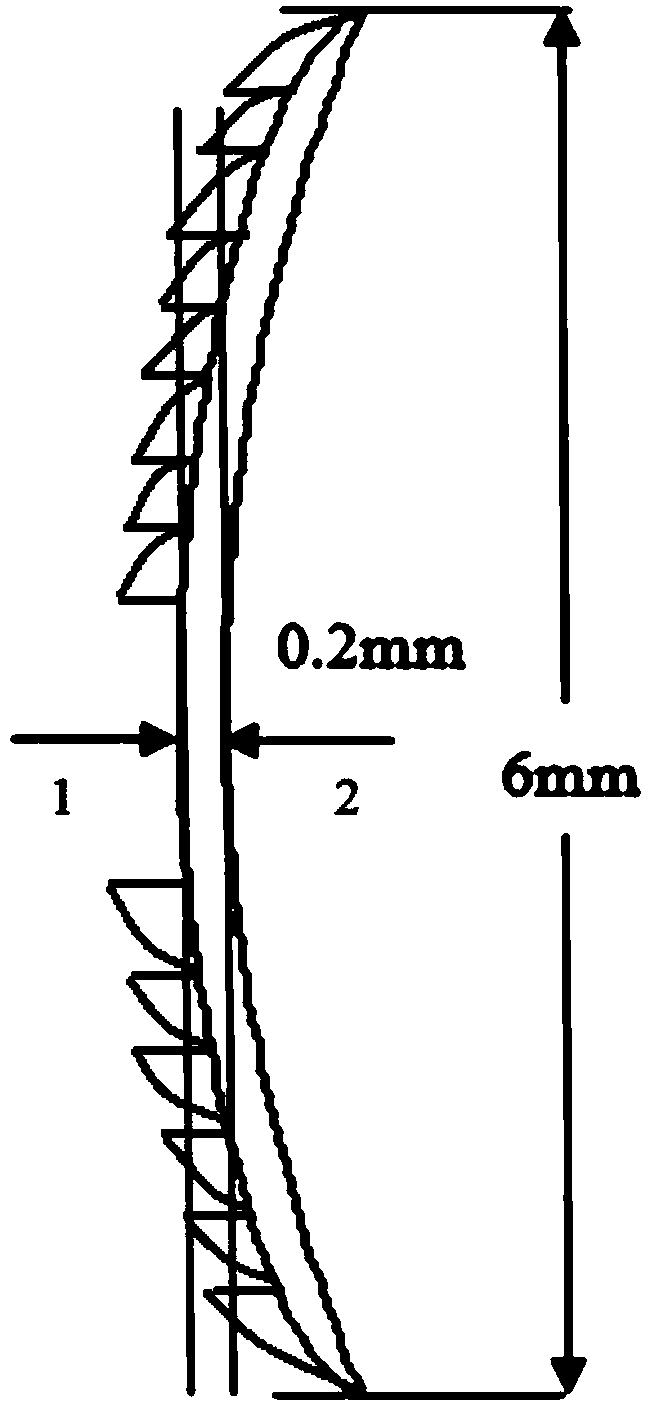

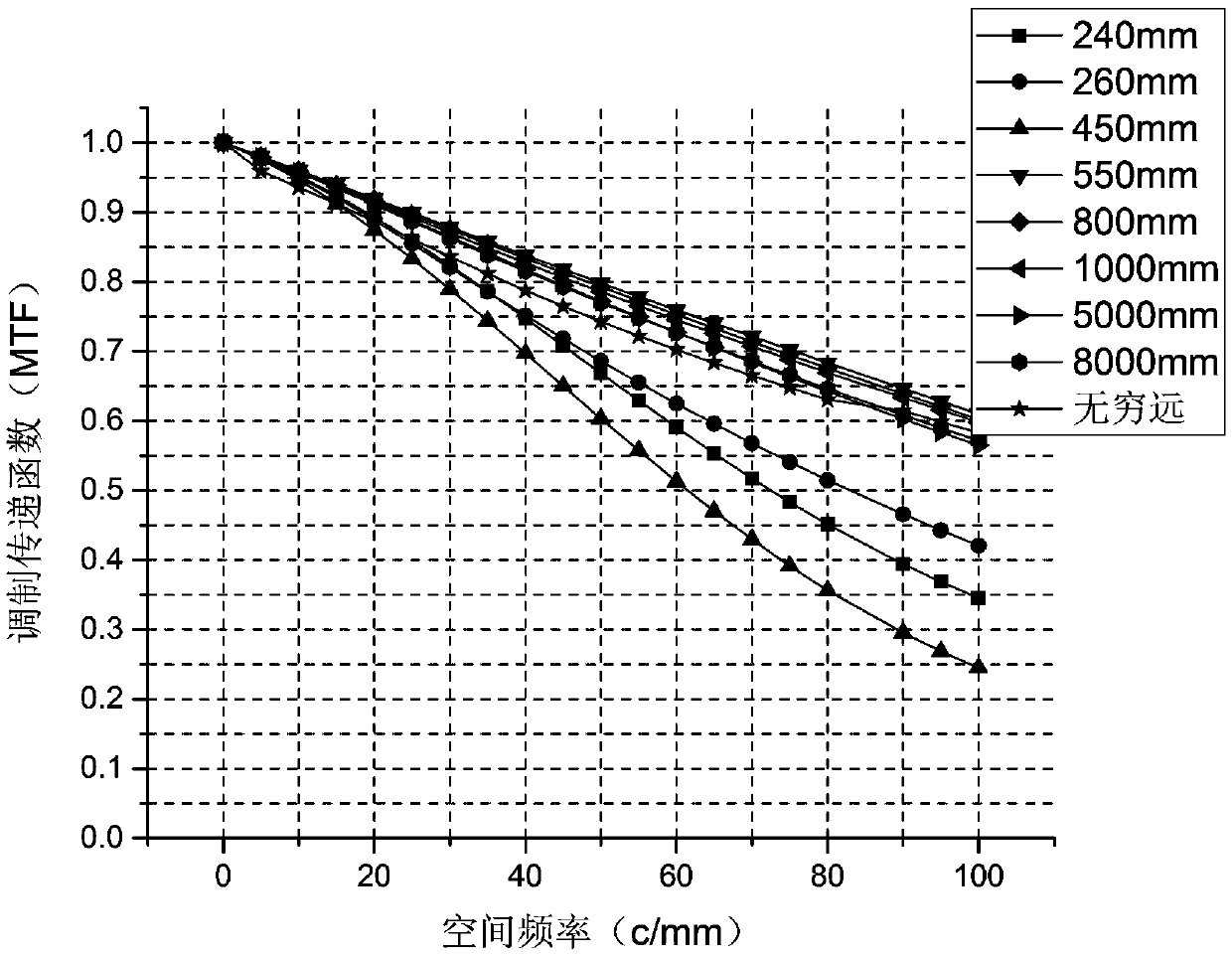

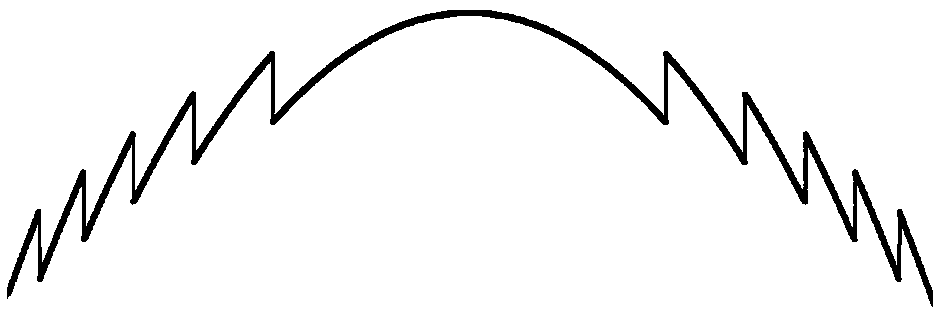

Aspheric diffraction type contact lens for correcting myopia and presbyopia

The invention discloses an aspheric diffraction type contact lens which is used for correcting myopia and presbyopia and has a certain eye regulation function. The diameter of the optical part of the contact lens is 6 mm, the front surface of the contact lens is an axial symmetry type convex aspheric surface, and a diffraction ring used for providing additional diopter is arranged on the front surface. The rear surface of the contact lens is attached to the cornea of people, and the radius of curvature is consistent with that of the anterior corneal surface. After the contact lens is put on, clear imaging can be achieved within the range from medium-range distance to long-range distance (450 mm-infinite distance) and near the read range (240 mm-260 mm) in a field of view which is + / -4 degrees. Furthermore, the contact lens also has the advantages that the extended depth of field is large, and vision stays stable along with pupil change.

Owner:NANKAI UNIV

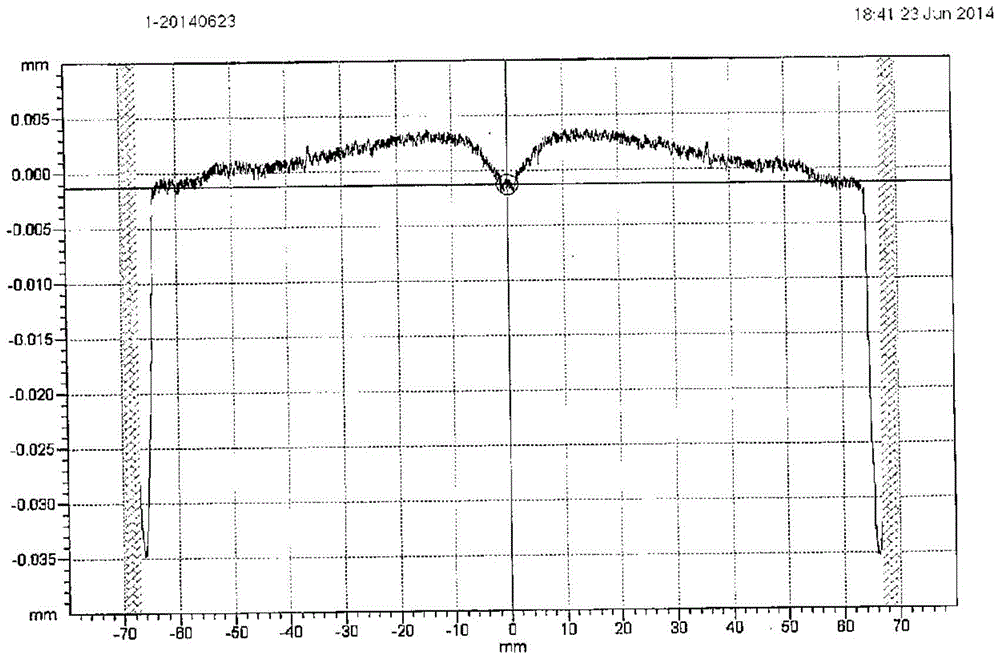

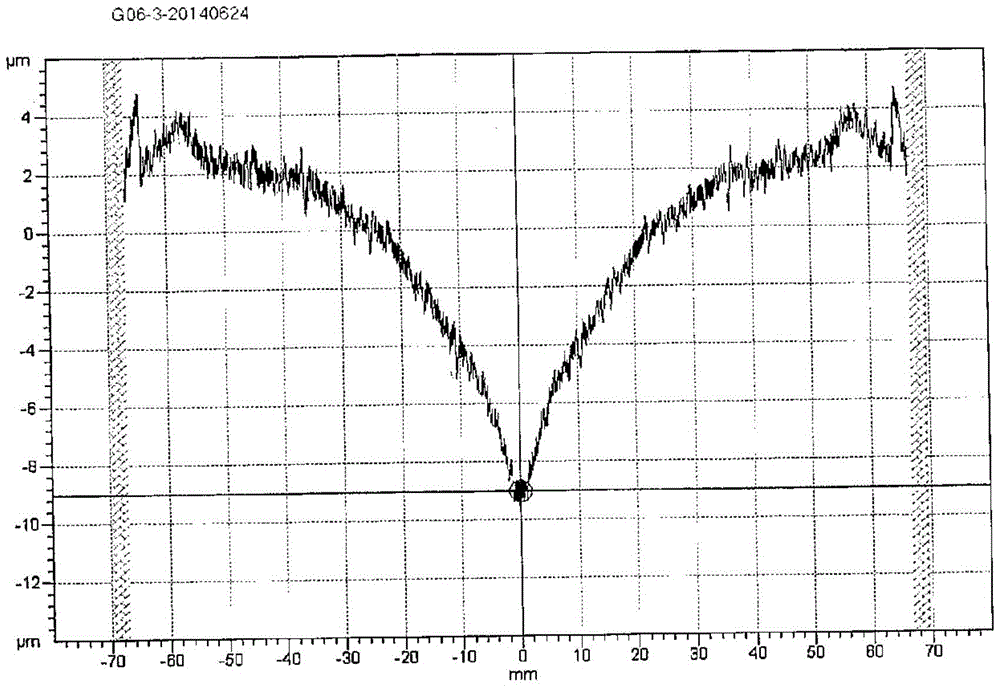

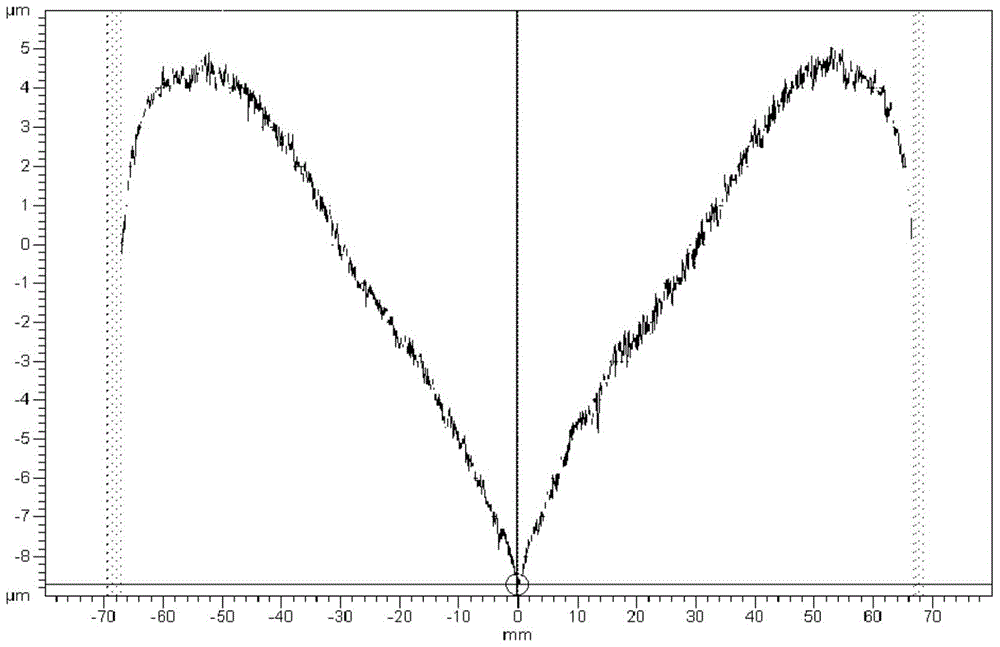

Compensation method for edge effect of high precision aspheric milling

ActiveCN104440385BImprove facial shapeReasonable facial shapeAutomatic control devicesMeasurement/indication equipmentsEdge effectsComputer science

Owner:SHANGHAI MODERN ADVANCED ULTRA PRECISION MFG CENT

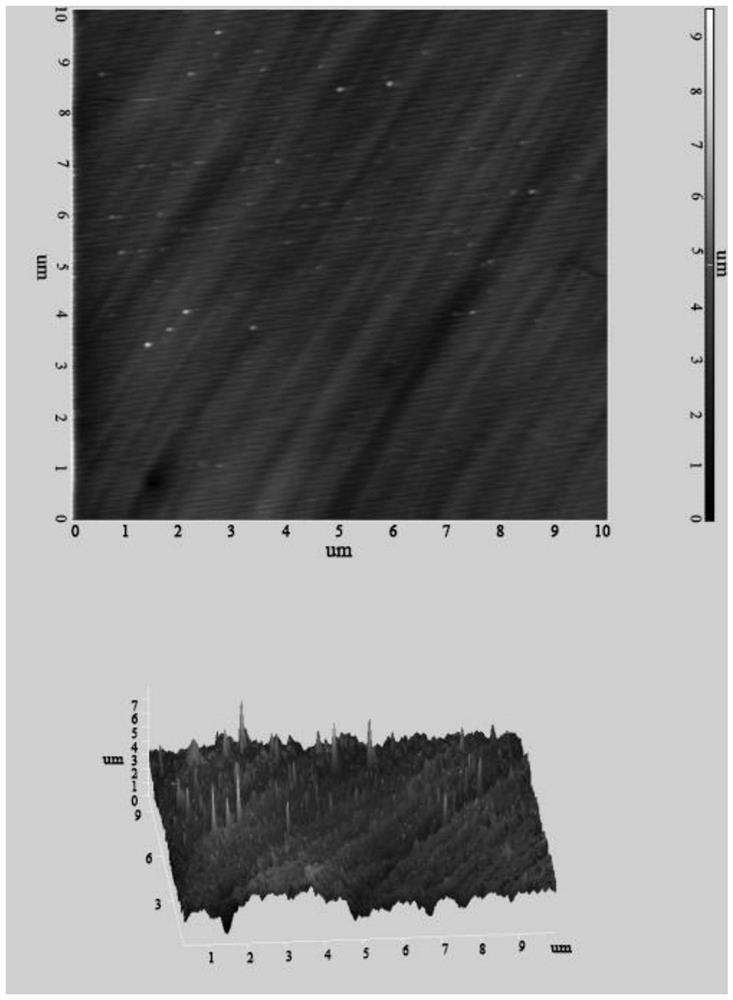

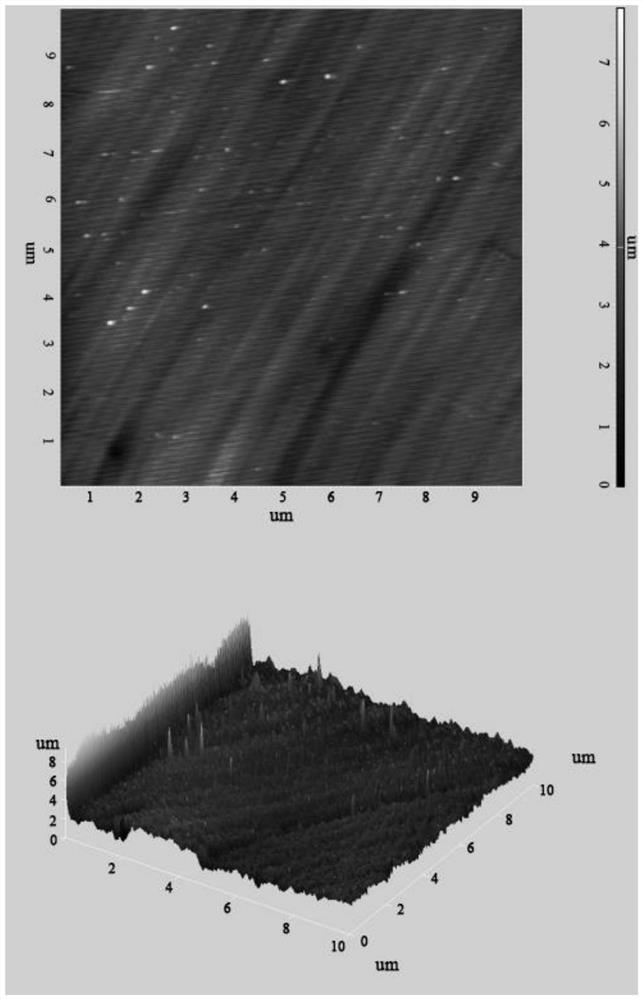

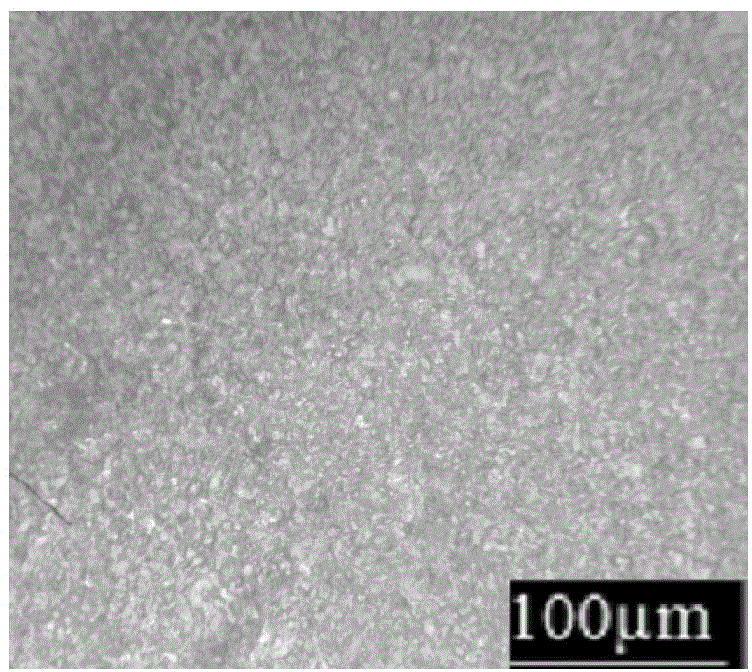

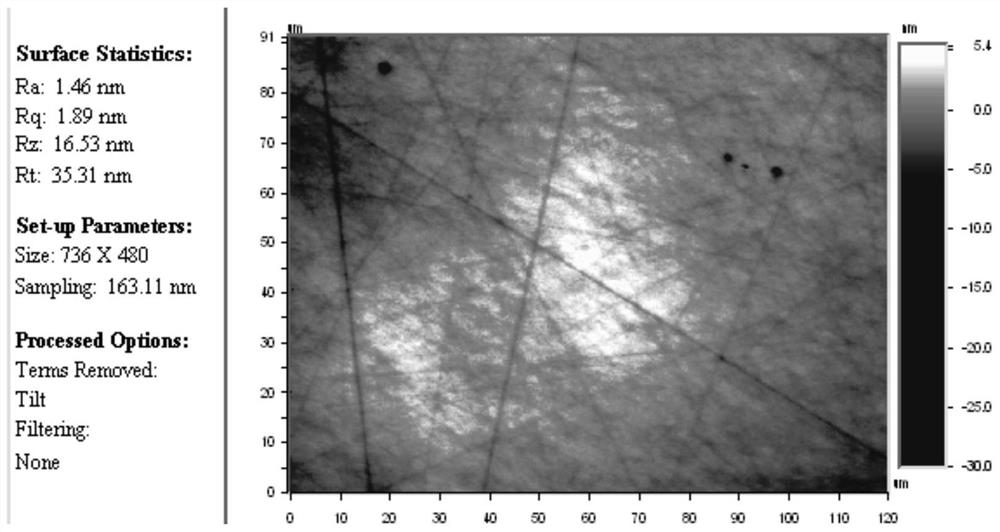

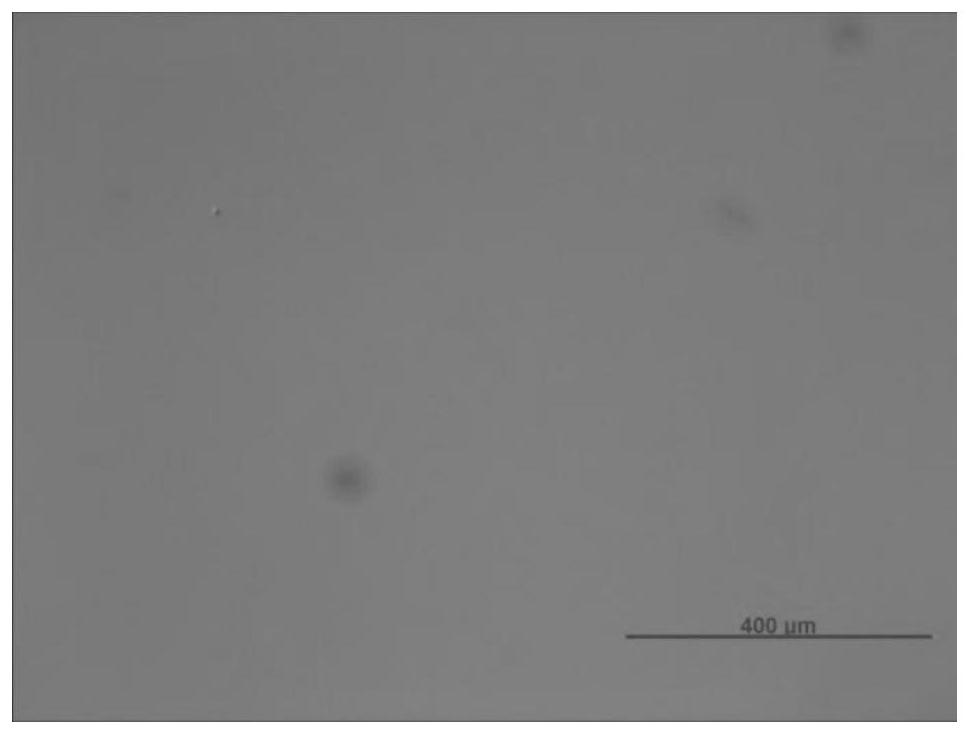

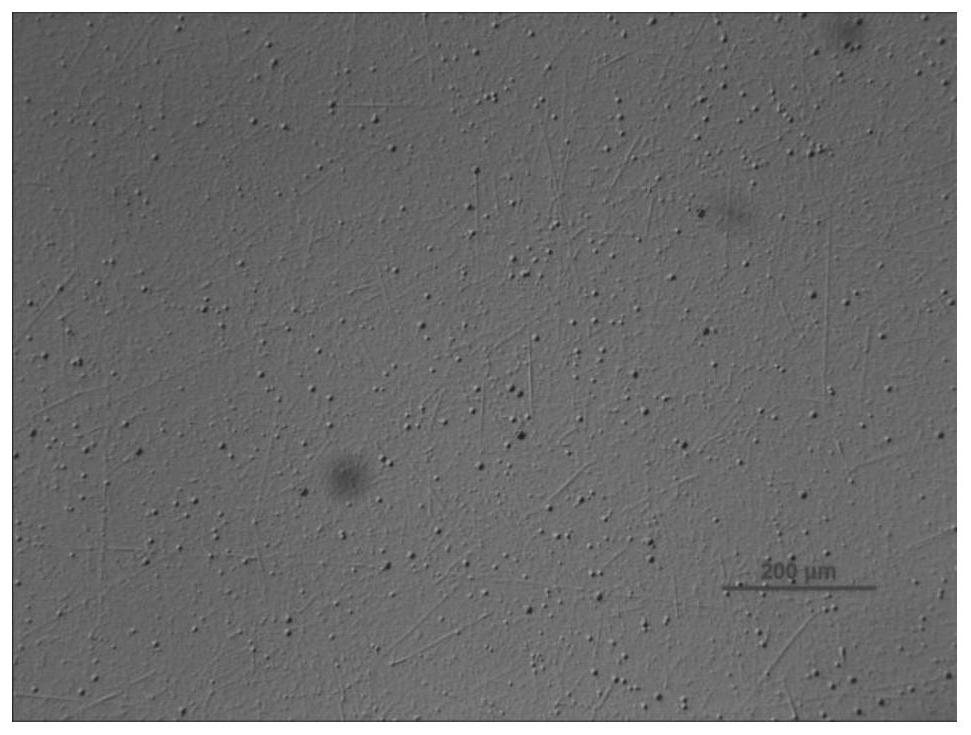

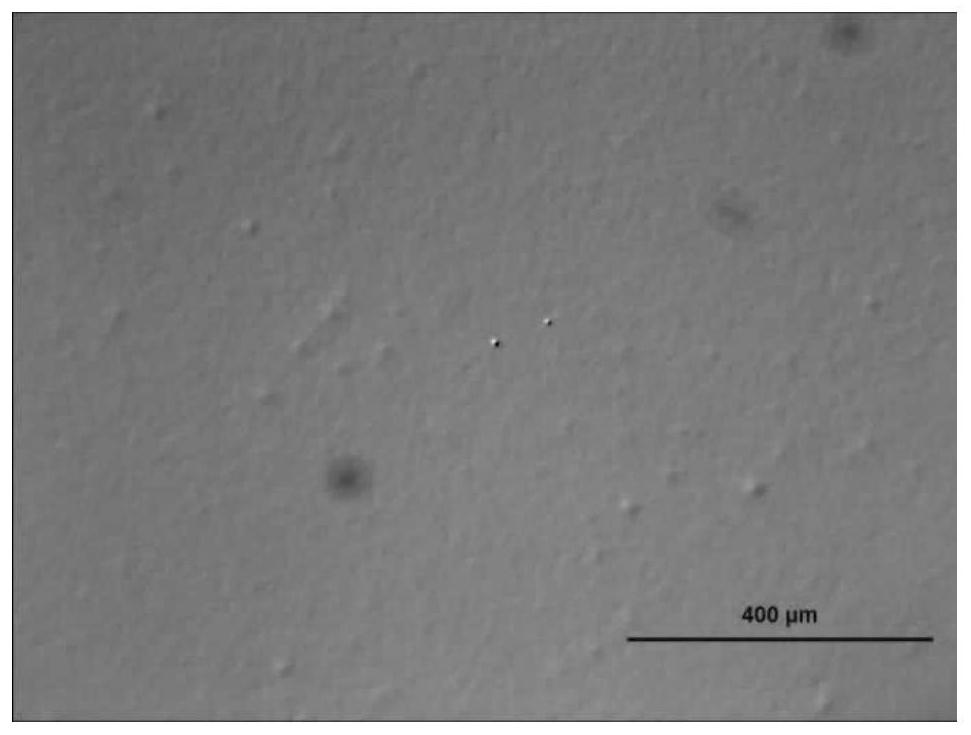

Method for obtaining super-smooth surface low-sub-surface-damage crystal

InactiveCN103231302BLow subsurface damageImprove facial shapeLapping machinesWork carriersMicroscopic observationBoron carbide

The invention relates to a method for obtaining super-smooth surface low-sub-surface-damage crystal. The method includes the following steps: (1) grinding crystal on a cast iron disc by using boron carbide with the specification as W1 as a grinding material; (2) polishing the crystal on an asphalt disc by using cerium oxide polishing liquid with the particle size as 1 mum; (3) soaking the crystal surface in an organic solvent and processing for 30-60 seconds in an ultrasonic mode; (4) polishing the crystal for 10-15 minutes on a polyurethane polishing gasket by using silicon dioxide polishing liquid with the particle size as 100 nm; (5) placing the crystal in the organic solvent, washing for 30-60 seconds in an ultrasonic mode, and observing the surface topography of the crystal by using a high-power microscope; and (6) if the crystal surface still has scratches, repeating the step (2) to step (5), replacing the cerium oxide polishing liquid with the particle size as 1 mum in the step (2) with cerium oxide polishing liquid with the particle size as 100-300 nm. Compared with the prior art, the method is simple to operate, high in processing efficiency and convenient to popularize.

Owner:TONGJI UNIV

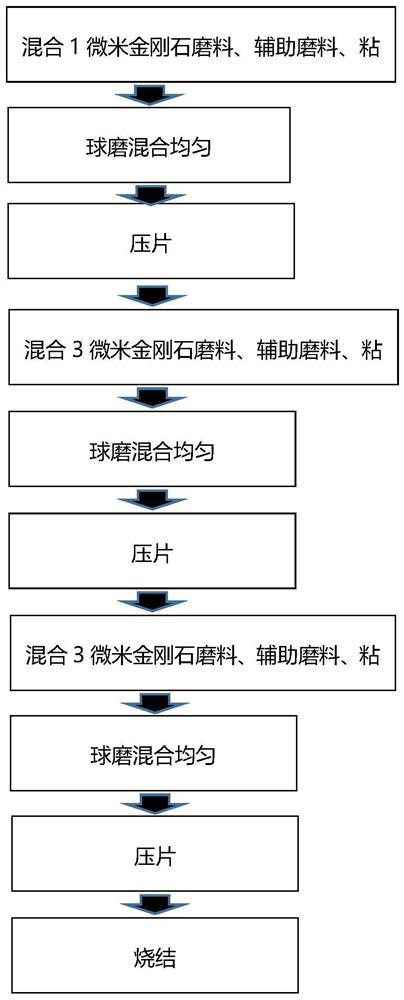

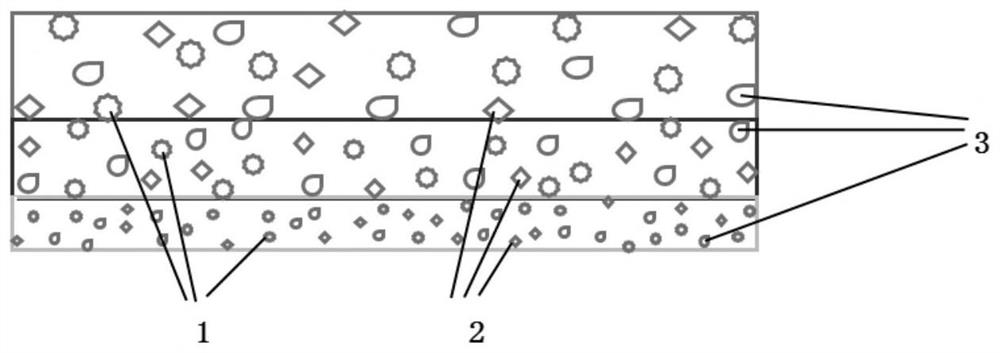

Preparation method of polishing disc for polishing superhard substrate slice and precise polishing method

ActiveCN113211337AAverage thickness difference is smallLow bending warpageGrinding devicesPolishingMachining

The invention relates to a preparation method of a polishing disc for polishing a superhard substrate slice and a precise polishing method, and belongs to a substrate machining technology. According to the novel preparation method of the polishing disc for polishing the substrate slice, the multi-layer composite polishing disc is used for precisely polishing the substrate slice, compared with a traditional substrate slice polishing technology, the technological process is greatly simplified, the polished substrate slice with the good surface type is obtained, and the polished substrate slice is small in average thickness difference and low in bending warping degree. The method is simple in process and easy to operate.

Owner:NANTONG UNIVERSITY

Large depth of focus aspheric diffractive intraocular lens

ActiveCN106491244BImprove facial shapeLarge depth of field performanceIntraocular lensIntraocular lensPolymethyl methacrylate

Owner:NANKAI UNIV

Optical imaging lens

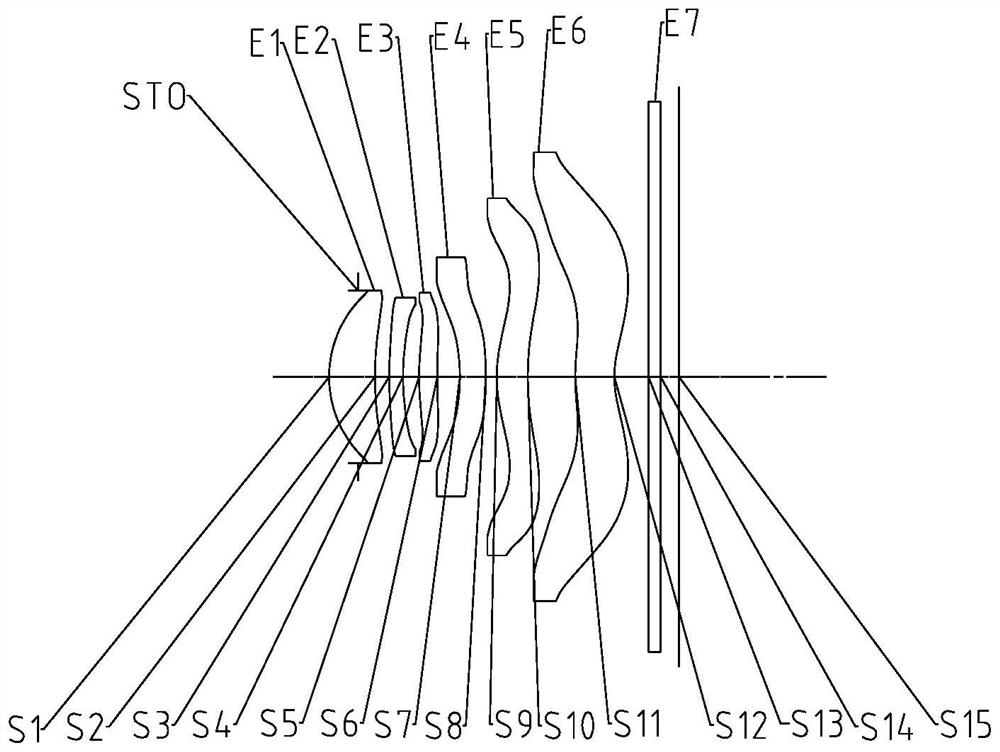

The invention discloses an optical imaging lens. The lens sequentially comprises, from the object side to the image side along an optical axis, a first lens withfocal power, a second lens with focal power, a third lens with negative focal power, a fourth lens with focal power and with the object side surface to be a convex surface, a fifth lens with focal power and with the object side surface to be a concave surface, a sixth lens with focal power, a seventh lens with focal power, and an eighth lens with focal power. The edge thickness ET7 of the seventh lens and the center thickness CT7 of the seventh lens on the optical axis meet the condition that ET7 / CT7 is larger than 0.5 and smaller than 1.0.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

Optical imaging lens

The invention discloses an optical imaging lens. The lens sequentially comprises a diaphragm, a first lens, a second lens, a third lens, a fourth lens, a fifth lens and a sixth lens from an object side to an image side along an optical axis; the first lens has focal power; the second lens has focal power, and the object side surface of the second lens is a concave surface; the third lens has positive focal power; the fourth lens has negative focal power, and the object side surface of the fourth lens is a convex surface; the fifth lens has focal power; and the sixth lens has focal power. The distance TTL from the object side surface of the first lens to the imaging surface of the optical imaging lens along the optical axis and the half ImgH of the diagonal length of an effective pixel area on the imaging surface of the optical imaging lens meet the condition that TTL / ImgH is smaller than 1.5. The effective focal length f4 of the fourth lens and the effective focal length f1 of the first lens meet the condition that f4 / f1 is larger than -9.0 and smaller than -3.5.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

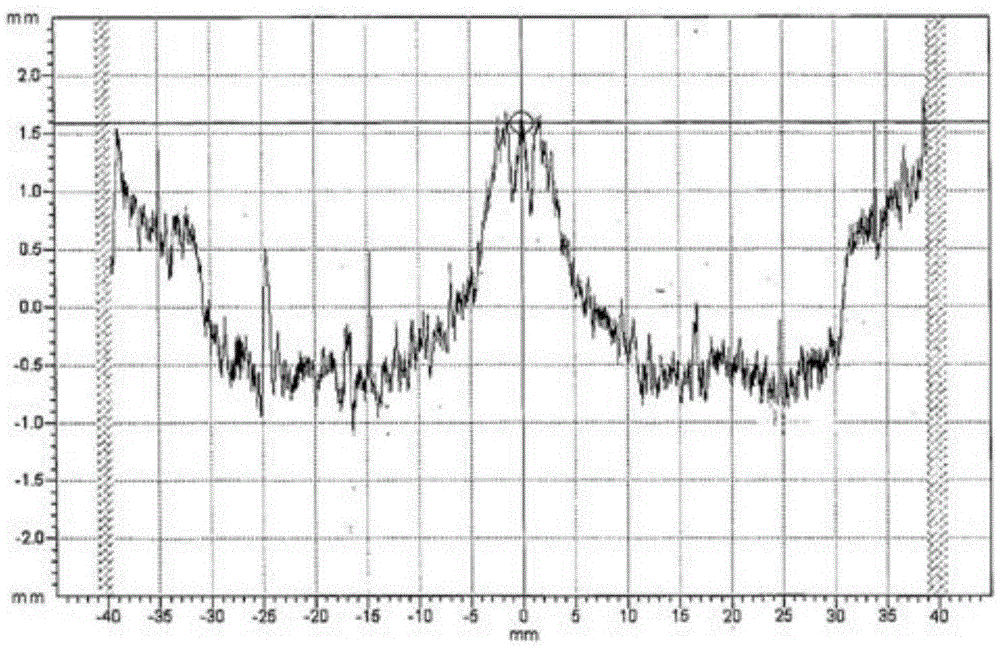

Compensation Method for Defects in Milling and Grinding of High Precision Aspheric Surface

ActiveCN104400588BImprove facial shapeReasonable facial shapeOptical surface grinding machinesGrinding feed controlData errorIndustrial engineering

A method for compensating for defects in high-precision aspheric milling and grinding, including processing the aspheric surface to be processed with a standard equation; using a profiler to detect the surface shape of the workpiece processed by the standard equation, and selecting the aspheric surface closest to the requirements of the drawing The radius value is used to adjust the positive and negative of the Y-axis direction of the tool; the profiler is used to detect the surface shape of the workpiece processed by the standard equation, and the detected deviation curve is observed to adjust the positive and negative of the X-axis direction of the tool; the present invention is effective Eliminate the center boss or overcut phenomenon caused by the error of the detection data, so that the surface shape of the workpiece becomes better and more reasonable, and meets the technical requirements.

Owner:SHANGHAI MODERN ADVANCED ULTRA PRECISION MFG CENT

Adjustable pressure device used for polishing heavy-calibre plane optical element

InactiveCN102049716BOvercome the disadvantage of uncontrollable pressureImprove facial shapeOptical surface grinding machinesEngineeringMechanical engineering

The invention provides an adjustable pressure device used for polishing a heavy-calibre plane optical element, relating to a pressure device. The adjustable pressure device used for polishing the heavy-calibre plane optical element, provided by the invention, is used for regulating the pressure intensity born by a polishing surface of a workpiece when being processed, is capable of improving the polishing quality of the workpiece and controlling the removal rate of materials, and has simple and practical structure. The adjustable pressure device is provided with a mass block and a fixture flat plate, wherein the mass block is used as a pressure source; the fixture flat plate is provided with a fulcrum bar, a base and an adsorption base film, the fulcrum bar is used for loading the mass block, the lower part of the base is connected with the adsorption base film, a base body and a film are arranged on the adsorption base film, the base is adsorbed on the surface of the workpiece through the film of the adsorption base film to ensure that the whole device is fixed on the corresponding part of the workpiece.

Owner:XIAMEN UNIV

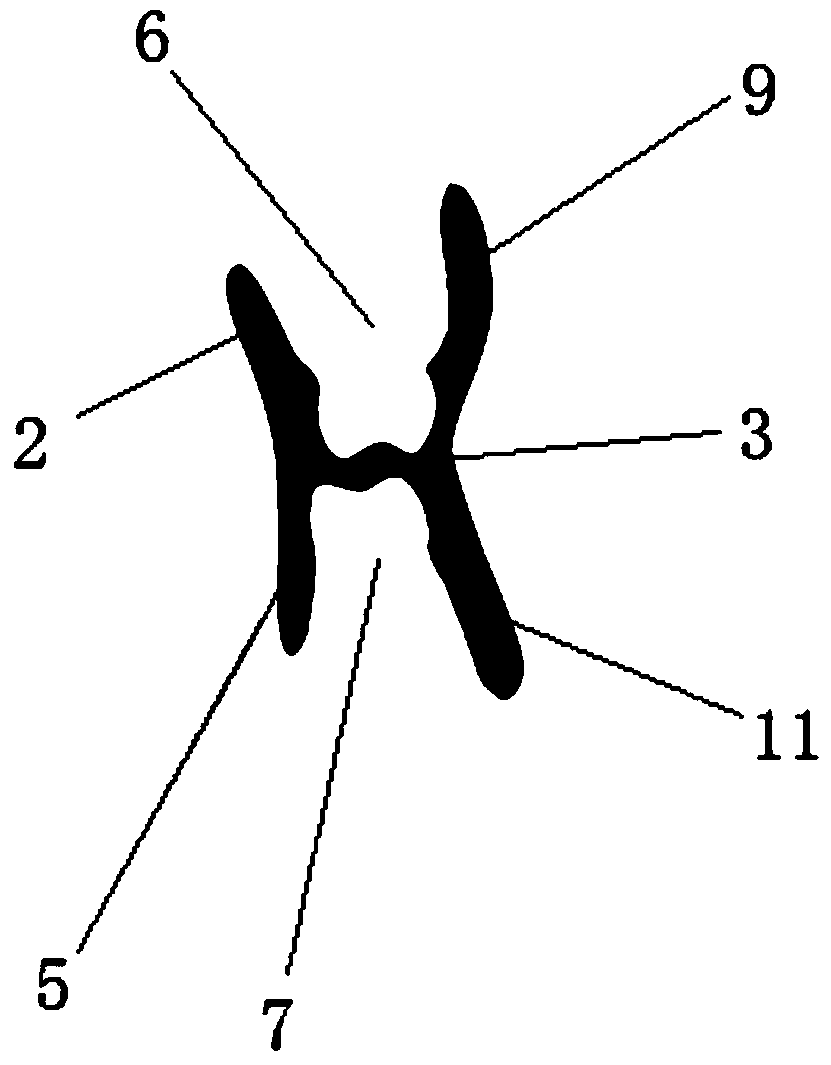

A type II personalized functional appliance and its manufacturing method and application

The invention discloses an II type appliance with a personalized function as well as a manufacture method and an application of the II type appliance. The II type appliance with the personalized function comprises a maxillary outer side base 1, a maxillary tongue side base 2, an occlusal pad 3, a mandible outer side base 4 and a mandible tongue side base 5, wherein the maxillary outer side base 1 and the maxillary tongue side base 2 are integrally connected through the occlusal pad 3 to form an upper tooth space 6, and the mandible outer side base 4 and the mandible tongue side base 5 are integrally connected through the occlusal pad 3 to form a lower tooth space 7. The II type appliance with the personalized function can promote growth of mandible and inhibit growth of maxilla, and the purpose of preventive or interruptive correction of functional II type malocclusion or mild bony II type malocclusion is achieved; correction is completed under the condition that tooth extraction for subtrahend is not adopted, the conditions that the front section of the upper dental arch becomes narrower and the side face of the upper dental arch is more umbilicate can be avoided, reverse occlusion of anterior teeth can be corrected, space is regained, dentition is aligned, the face shape is improved, and the II type appliance with the personalized function has a good application prospect.

Owner:STOMATOLOGY AFFILIATED STOMATOLOGY HOSPITAL OF GUANGZHOU MEDICAL UNIV

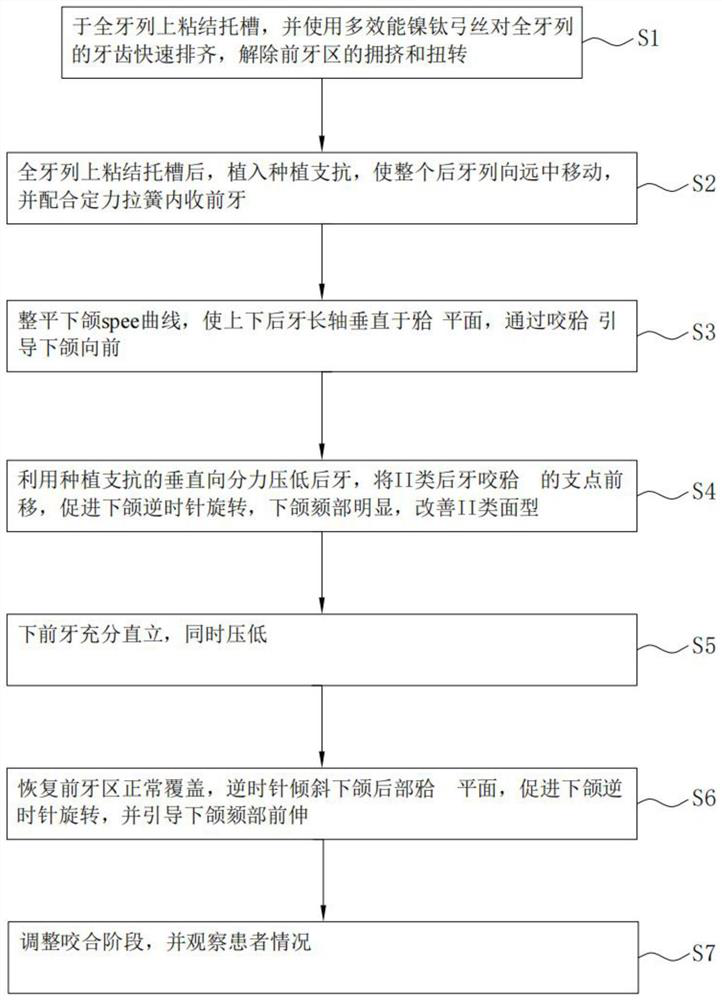

Method for correcting class II occlusion malformation

The embodiment of the invention discloses a bony class-II malformation correction method which comprises the following steps: quickly aligning teeth by adopting a multi-effect nickel-titanium arch wire, adducting anterior teeth by utilizing an anchorage nail and a constant-force tension spring, distally erecting upper posterior teeth, leveling a lower jaw spee curve, rotating a mandible anticlockwise, stretching a mandible chin forwards, reducing the heights of the upper posterior teeth and the lower posterior teeth, and promoting the mandible to rotate anticlockwise. And the lower anterior teeth are erected on the basal bone and are simultaneously depressed. In the later treatment period, when the upper anterior teeth reach the standard position, the lower mandibular anterior teeth are fully erected in the basal bone, but the anterior teeth cover a large area, a TMA wire is used for bending and raising in cooperation with oblique guiding and (or) the lower mandibular to conduct short-distance II-type traction, a rear tooth occlusion relation is established, the lower mandibular bone is promoted to move forwards, and the face of a II-type patient is improved. According to the invention, complicated operations such as operations are not needed, the orthopedic II-type correction of adults can be completed, and the facial forms of maxillary protrusion and mandibular retrograde can be effectively improved.

Owner:北京非凡禾禾医疗器械有限公司

Optical imaging lens

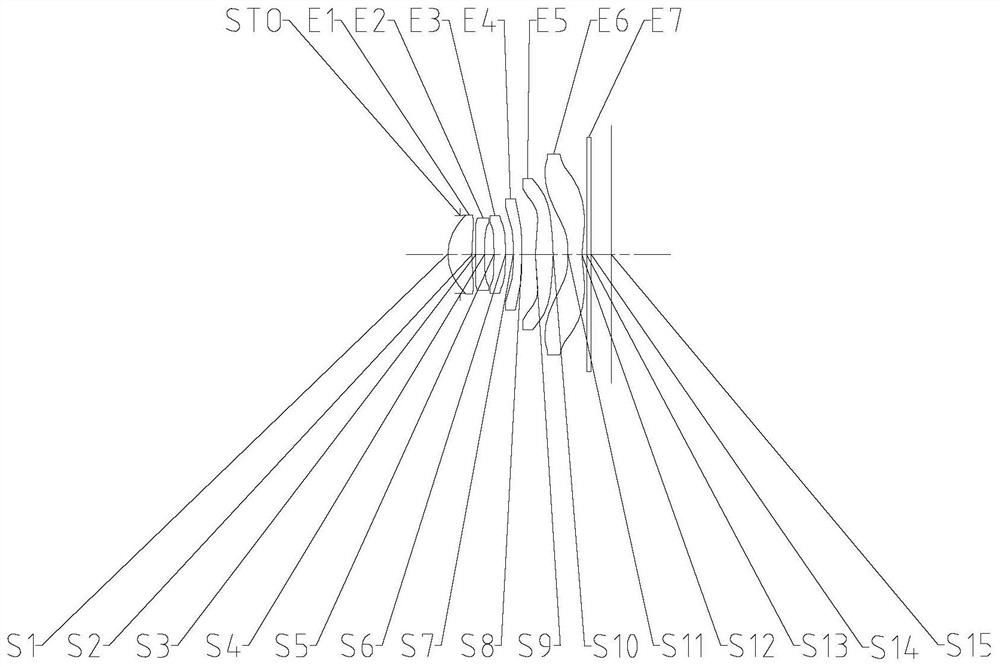

PendingCN113985574AImprove facial shapeIncreasing the thicknessOptical elementsOphthalmologyOptical axis

The invention discloses an optical imaging lens which sequentially comprises, from an object side to an image side along an optical axis, a first lens having focal power; a second lens having focal power, wherein the object side surface of the second lens is a convex surface, and the image side surface of the second lens is a convex surface; a third lens having focal power; a fourth lens having focal power; a fifth lens having negative focal power; a sixth lens having focal power; and a seventh lens having focal power. The effective focal length f of the optical imaging lens and the entrance pupil diameter (EPD) of the optical imaging lens meet the condition that f / EPD is less than 1.5. The distance TTL from the object side surface of the first lens to the imaging surface of the optical imaging lens along the optical axis, the half ImgH of the diagonal length of an effective pixel area on the imaging surface and the half Semi-FOV of the maximum field angle of the optical imaging lens meet the following condition: TTL / (ImgH * TAN (Semi-FOV)) < 1.7.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

Quartz and methods of increasing its resistance to laser damage

ActiveCN108455870BIncreased resistance to laser damageEasy to fillCoatingsLaser damageSilicon dioxide

The invention relates to the field of optical materials, in particular to a quartz and a method for increasing the anti-laser damage performance of the quartz. The method for increasing the anti-laser damage performance of quartz comprises the following steps: depositing silicon dioxide on the quartz substrate after etching the quartz substrate; while depositing the silicon dioxide, depositing the deposited silicon dioxide Silicon is melted. It can completely remove smaller micro-cracks by etching, and at the same time, can completely expose larger micro-cracks and passivate the crack tip, which facilitates the filling and repair of micro-cracks in the subsequent cladding process. The fluidity of fused silica is then used to repair and fill the cracks, thereby improving the mechanical properties of fused silica and ultimately improving its laser damage resistance. At the same time, the large-area uniform deposition and cladding glass coating makes the entire surface of the fused silica have a better surface shape.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

Optical imaging lens

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

Optical imaging lens

The present application discloses an optical imaging lens, comprising in sequence from the object side to the image side along an optical axis: a first lens with optical power; a second lens with positive optical power; and a third lens with optical power; a fourth lens with negative power; a fifth lens with power; a sixth lens with positive power; and a seventh lens with power. The material of at least three lenses in the first lens to the fourth lens is plastic. The material of the fifth lens is glass, and the object side surface and the image side surface are spherical surfaces. The effective focal length f of the optical imaging lens and the entrance pupil diameter EPD of the optical imaging lens satisfy: f / EPD<1.25.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

Optical imaging lens

PendingCN114265180AImprove facial shapeIncreasing the thicknessOptical elementsOphthalmologyOptical axis

The optical imaging lens sequentially comprises a first lens, a second lens, a third lens and a fourth lens from an object side to an image side along an optical axis, a second lens; a third lens; the fourth lens has negative focal power; a fifth lens element; and a sixth lens. The distance TTL from the object side surface of the first lens to the imaging surface of the optical imaging lens along the optical axis and half ImgH of the length of a diagonal line of an effective pixel area on the imaging surface meet TTL / ImgHlt; and 1.3. The aperture number Fno of the optical imaging lens meets the following formula: Fnolt; 1.8).

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

Optical imaging lens

PendingCN113917659AWith telephoto characteristicsImprove image qualityOptical elementsOphthalmologyOptical axis

The invention discloses an optical imaging lens. The optical imaging lens sequentially comprises, from an object side to an image side along an optical axis: a first lens having positive focal power; a second lens having negative focal power; a third lens having focal power; a fourth lens having focal power, the image side surface of the fourth lens being a convex surface; and a fifth lens having negative focal power, and the object side surface of the fifth lens being a concave surface; wherein the distance TTL from the object side surface of the first lens to the imaging surface of the optical imaging lens on the optical axis and the total effective focal length f of the optical imaging lens meet the condition that TTL / f is less than 1.1; and the combined focal length f123 of the first lens, the second lens and the third lens and the combined focal length f45 of the fourth lens and the fifth lens meet the condition that f123 / f45 is more than -0.8 and less than -0.3.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

Optical imaging lens

ActiveCN114280761AImprove facial shapeIncreasing the thicknessOptical elementsOphthalmologyOptical axis

The optical imaging lens sequentially comprises a first lens, a second lens, a third lens and a fourth lens from an object side to an image side along an optical axis, a second lens; the object side surface of the third lens is a concave surface, and the image side surface of the third lens is a convex surface; a fourth lens; a fifth lens element; and a sixth lens. The distance TTL from the object side surface of the first lens to the imaging surface of the optical imaging lens along the optical axis and half ImgH of the length of a diagonal line of an effective pixel area on the imaging surface meet TTL / ImgHlt; and 1.25. Half ImgH of the diagonal line length of the effective pixel area on the imaging surface is 5 mmlt; and ImgH. At least one of the first lens to the sixth lens is made of glass.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

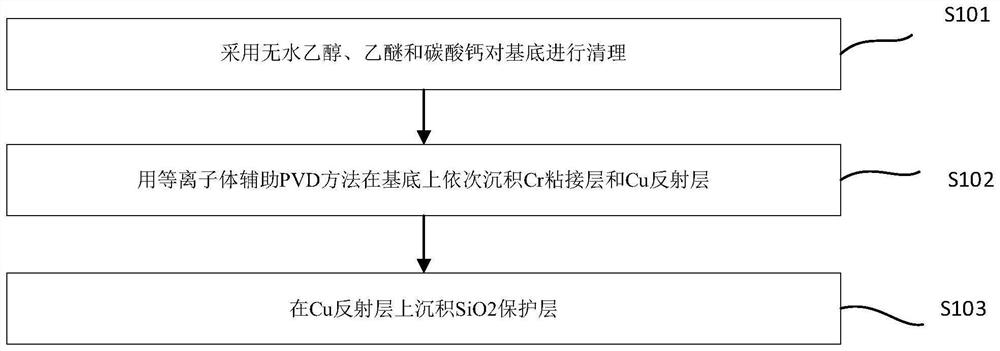

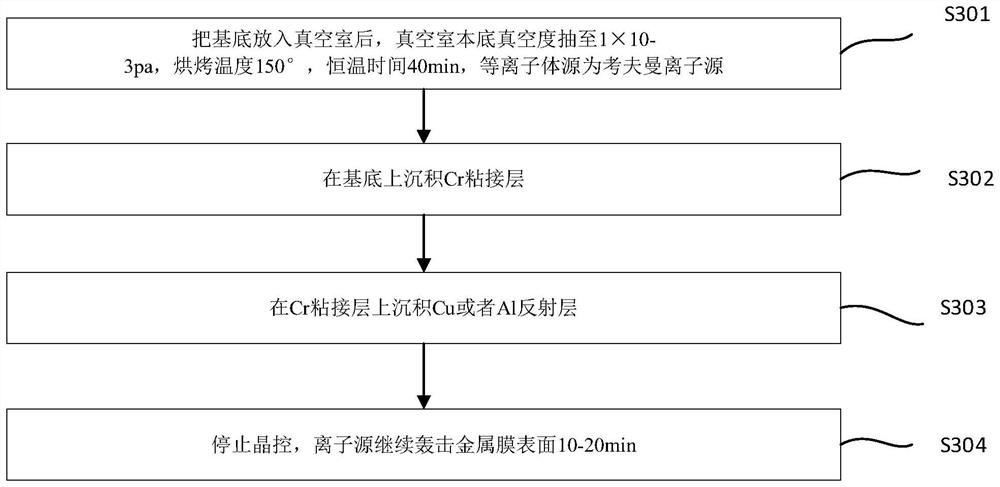

Method for improving white points on surface of metal film

PendingCN114369791AImprove surface qualityImprove facial shapeVacuum evaporation coatingSputtering coatingThin membraneMetal membrane

The invention relates to the field of optical elements, in particular to a method for improving white dots on the surface of a metal film, which comprises the following steps: cleaning a substrate by using absolute ethyl alcohol, diethyl ether and calcium carbonate; sequentially depositing a Cr bonding layer and a Cu reflecting layer on the substrate by using a plasma-assisted PVD (Physical Vapor Deposition) method; and depositing a SiO2 protective layer on the Cu reflecting layer. Firstly, a bonding layer is deposited, the bonding force between a substrate and a Cu or Al film is increased, and ion source bombardment is adopted during deposition of the Cu or Al film, so that protrusions of the metal film layer are flattened, the surface quality of the metal film layer is better, the number of white points is effectively reduced, and the reflectivity of the metal film layer is improved. And a layer of oxide hard protective film is plated outside the metal film, so that the hardness of the reflecting film is increased, and the reflecting film is ensured to pass an environmental test.

Owner:重庆四联特种装备材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

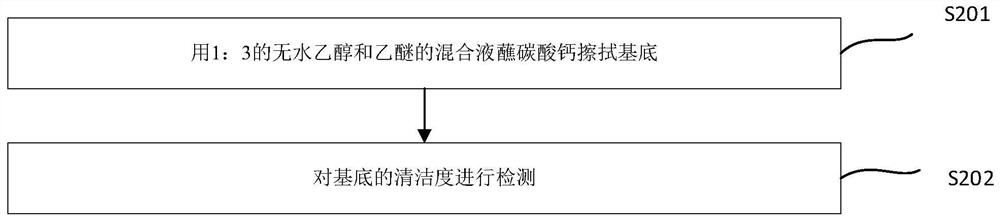

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com