Method for improving white points on surface of metal film

A technology of metal thin film and white spots, applied in metal material coating technology, ion implantation plating, coating, etc., can solve the problems of white spots on the surface of metal films to reduce reflectivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

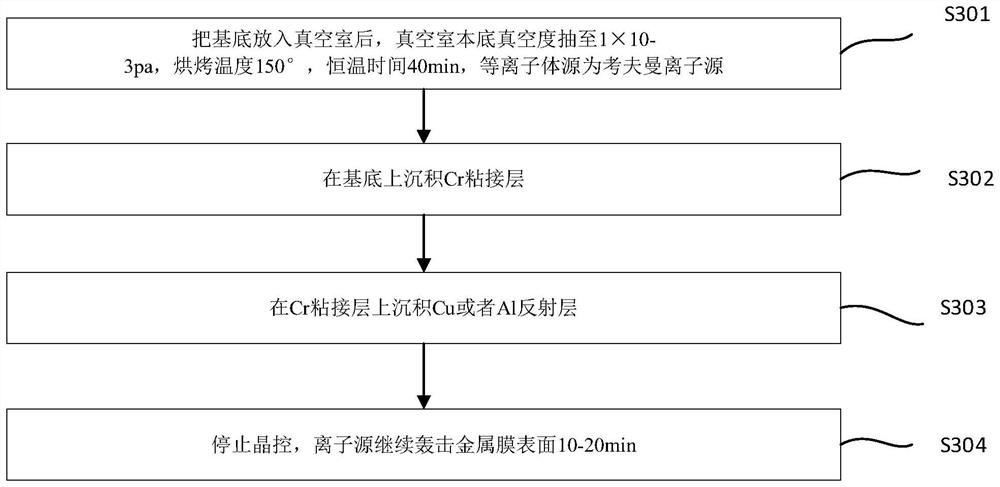

[0027] The present invention adopts ZZS-1600 vacuum coating machine and plasma-assisted physical vapor deposition method to coat the process.

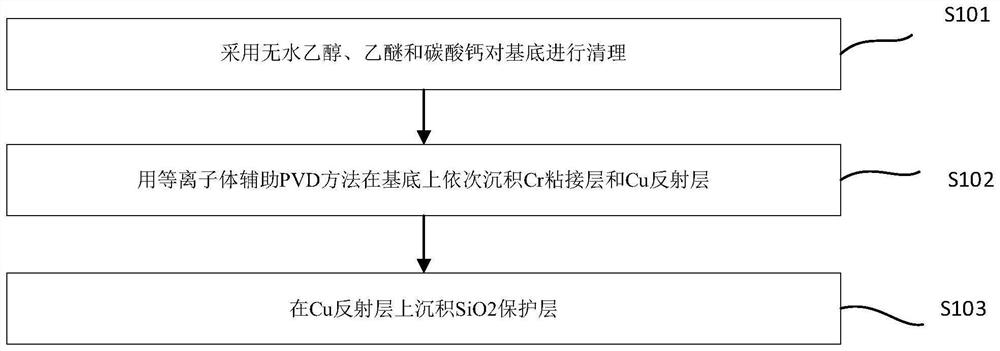

[0028] see Figure 1 to Figure 4 , the invention provides a method for improving white spots on the surface of a metal film, comprising:

[0029] S101 uses absolute ethanol, ether and calcium carbonate to clean the substrate;

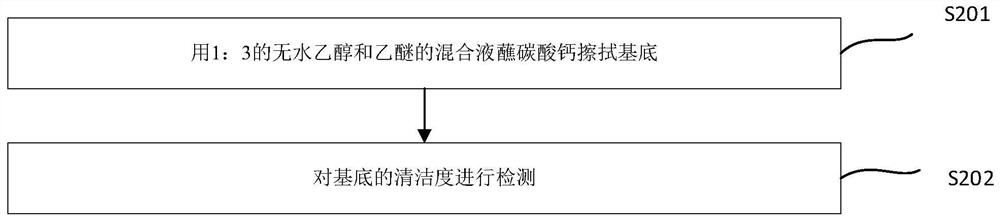

[0030] The specific steps are:

[0031] S201 Wipe the substrate with a 1:3 mixture of absolute ethanol and ether dipped in calcium carbonate;

[0032] Material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com