Method for obtaining super-smooth surface low-sub-surface-damage crystal

A technology of sub-surface damage and ultra-smooth surface, applied in the direction of working carrier, grinding device, grinding machine tool, etc., to achieve the effect of reducing process cost, process stability and strong pertinence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Grinding and polishing of YCOB crystals:

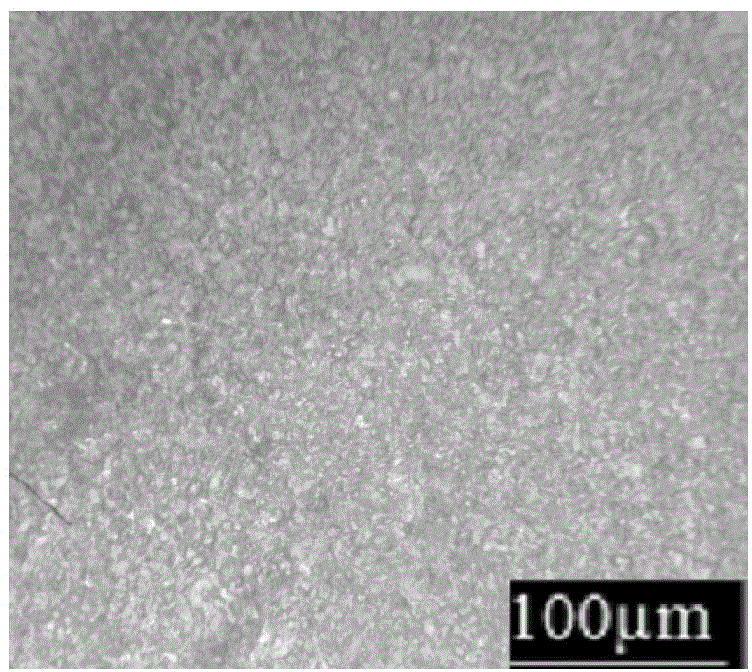

[0030] 1. Grinding --- Fix the YCOB crystal on the loading plate with paraffin, and stick a protective sheet around the crystal. The crystal is ground on a cast iron plate, with boron carbide as the abrasive W1, and ground on a Nanjing Lisheng double-axis precision grinding and polishing machine JM 030.2. The surface morphology of the crystal is as follows figure 1 shown. This can ensure the grinding speed while reducing the depth of the damaged layer and shorten the subsequent polishing time. On the double-axis polishing machine, the self-made clamping tool is used to avoid the crystal sagging caused by the unbalanced moment when the axis is moving, so as to ensure the crystal surface shape is good.

[0031] 2. Make the rubber plate --- select No.55 asphalt from GUGOLZ company in Switzerland and put it on the loading plate, fix a circle of tape around it, gradually increase the heating temperature, and try to avoid stirring ...

Embodiment 2

[0038] A method for obtaining ultra-smooth surface and low subsurface damage crystal, the method comprises the following steps:

[0039] (1) Grinding: Paste a protective sheet around the crystal, fix the crystal on the abrasive tool with paraffin, then clamp the crystal with a clamping tool, and use boron carbide with a specification of W1 as the abrasive on a two-axis precision grinding and polishing machine. And cooperate with the cast iron disc to grind the crystal, quickly remove the damage layer caused by the previous process, so that the crystal surface has a good shape and the flatness reaches the standard;

[0040] (2) Coarse polishing: After preparing the asphalt disk and correcting the surface type and roughness of the asphalt disk, use a cerium oxide polishing solution with a particle size of 1 μm to mechanically polish the crystal on the asphalt disk until the surface roughness of the crystal reaches 1nm or basically no scratches , wherein, the temperature of rough...

Embodiment 3

[0046] A method for obtaining ultra-smooth surface and low subsurface damage crystal, the method comprises the following steps:

[0047] (1) Grinding: Paste a protective sheet around the crystal, fix the crystal on the abrasive tool with paraffin, then clamp the crystal with a clamping tool, and use boron carbide with a specification of W1 as the abrasive on a two-axis precision grinding and polishing machine. And cooperate with the cast iron disc to grind the crystal, quickly remove the damage layer caused by the previous process, so that the crystal surface has a good shape and the flatness reaches the standard;

[0048] (2) Coarse polishing: After preparing the asphalt disk and correcting the surface type and roughness of the asphalt disk, use a cerium oxide polishing solution with a particle size of 1 μm to mechanically polish the crystal on the asphalt disk until the surface roughness of the crystal reaches 1nm or basically no scratches , wherein the temperature of rough ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com