Preparation process of hydraulic anti-crack low-shrinkage high-performance concrete and preparation device

A kind of high performance concrete, technology of preparation device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

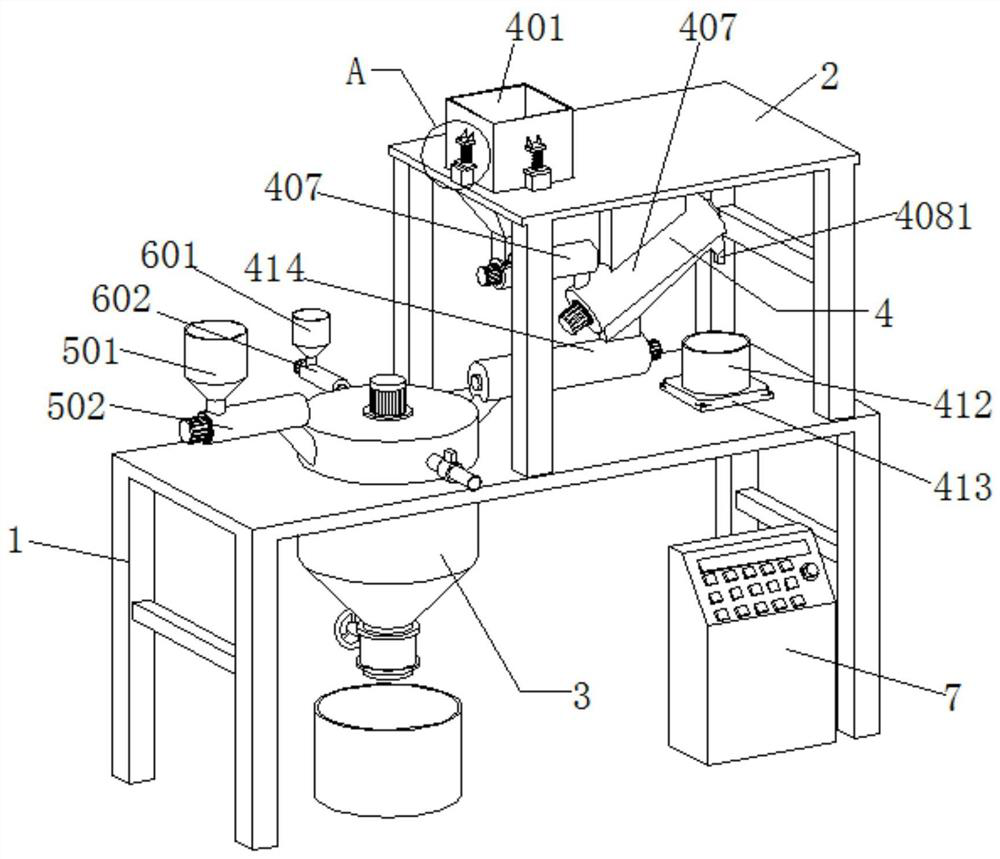

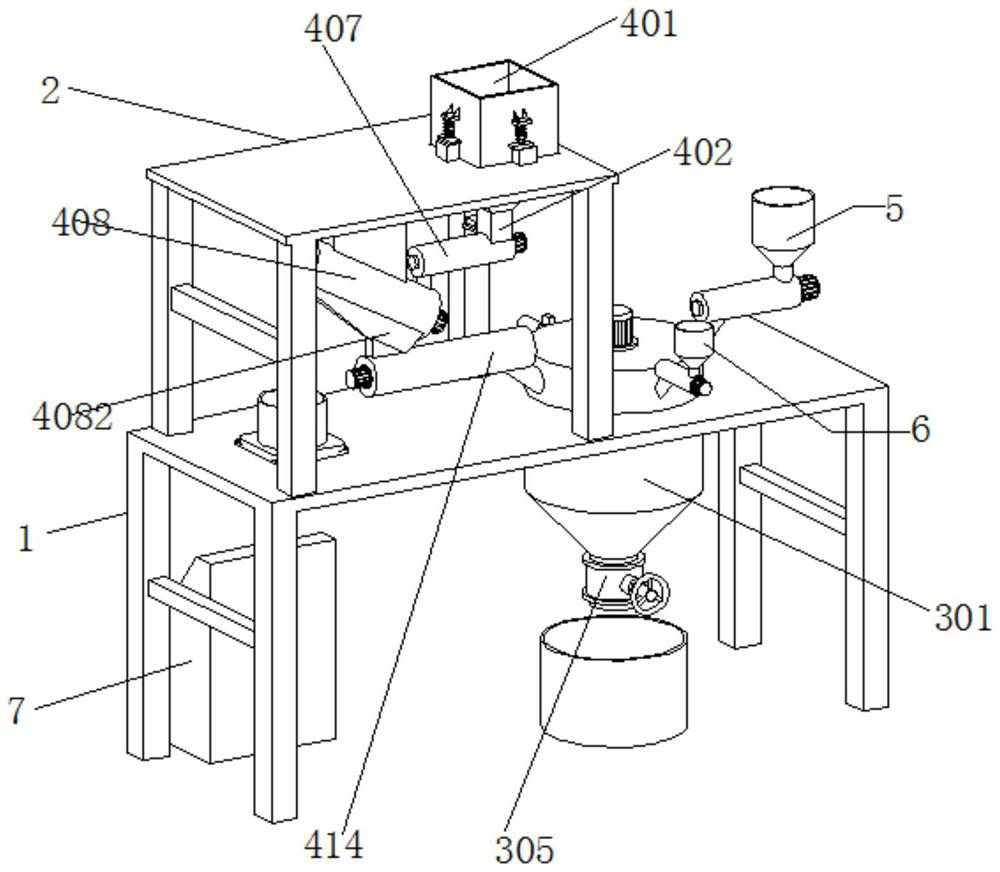

[0056] This embodiment 1 discloses a preparation device for hydraulic crack-resistant low-shrinkage high-performance concrete, refer to the attached figure 1 And attached figure 2 , its main components include bottom frame 1, top frame 2, stirring and mixing device 3, aggregate screening and quantitative feeding device 4, cement quantitative feeding device 5, auxiliary material quantitative feeding device 6 and control cabinet 7. When setting, the top frame 2 is arranged on one end of the upper surface of the bottom frame 1, and the stirring and mixing device 3 is fixedly installed on the bottom frame 1.

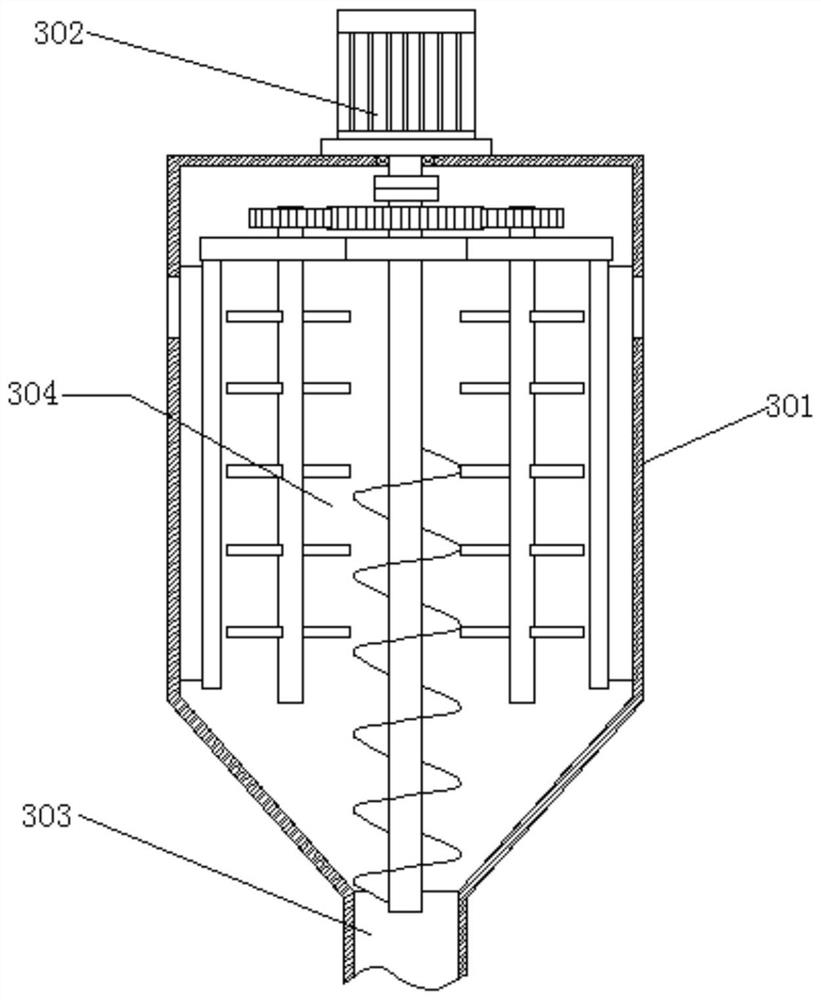

[0057] Reference attached image 3 , attached Figure 4 And attached Figure 5 , its stirring and mixing device 3 comprises a stirring and mixing tank 301, a stirring motor 302 arranged at the center of the upper surface of the stirring and mixing tank 301 and a discharge pipe 303 connected to the lower end of the stirring and mixing tank 301, and the discharge pipe 303 ...

Embodiment 2

[0063] Embodiment 2 discloses a preparation device for hydraulic crack-resistant low-shrinkage high-performance concrete improved on the basis of Embodiment 1. Its similarities with Embodiment 1 will not be described again, and the differences are:

[0064] Please refer to the attached image 3 , attached Figure 5 In this embodiment 2, a scraper 3048 vertically arranged and attached to the inner wall of the stirring and mixing tank 301 is connected to the outer end of each end of the fork-shaped plate 3043 . After a batch of concrete processing is completed, the stirring motor 302 continues to drive the scraper plate 3048 to scrape and clean the mixing tank 301, which can effectively prevent scaling on the inner wall of the mixing tank 301 and cause serious damage to the subsequent concrete preparation. influences.

[0065] Reference attached Figure 8 , the present embodiment 2 is also provided with a vibrating motor 400 on the lower surface of the screening machine casin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com