Injection mold with linkage type undercut demolding mechanism

A demoulding mechanism and injection mold technology, applied in the field of mold manufacturing, can solve problems such as high labor costs and low production efficiency, achieve ideal working results, improve production efficiency, and eliminate interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

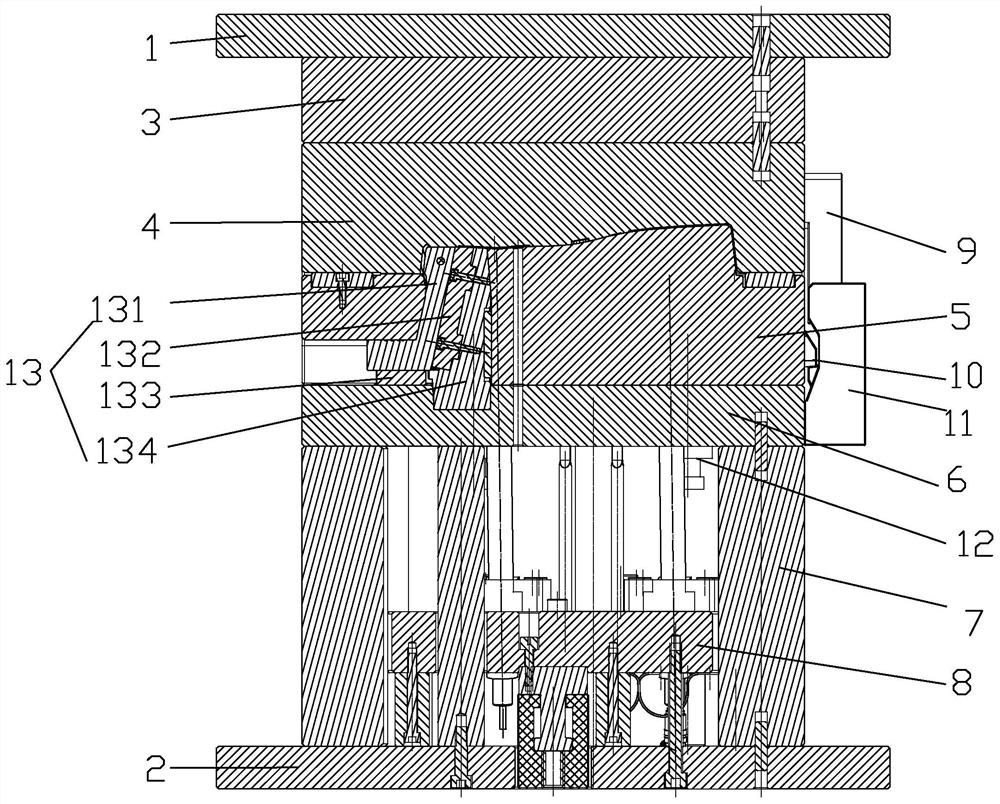

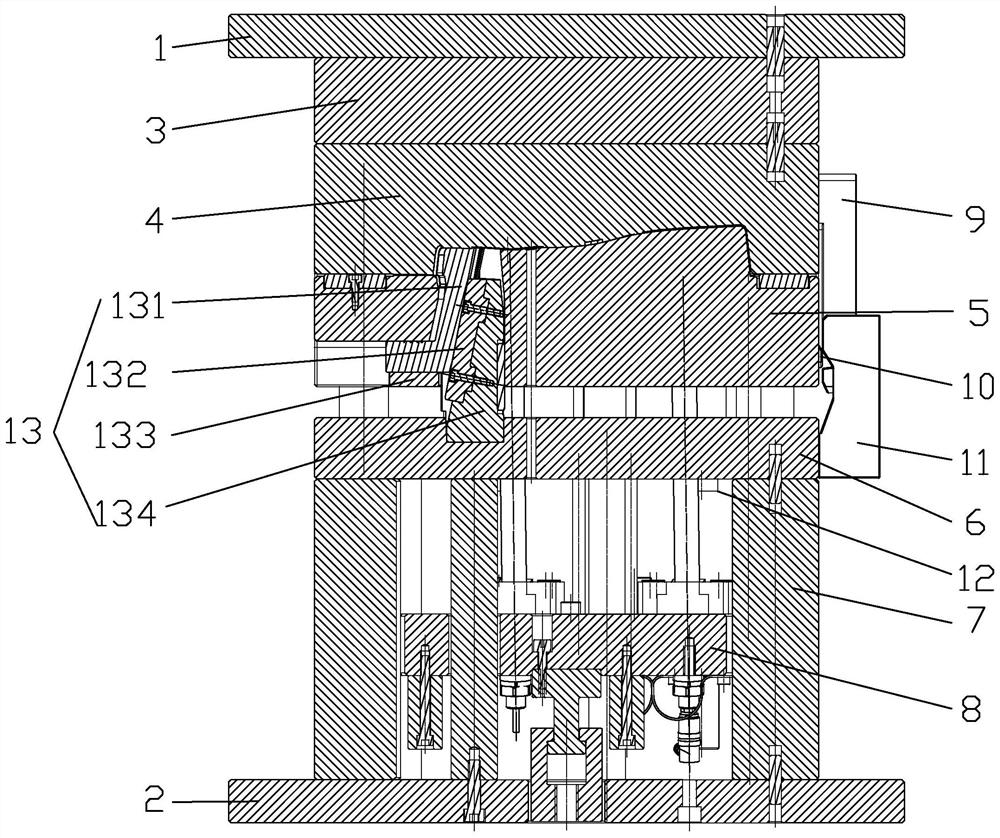

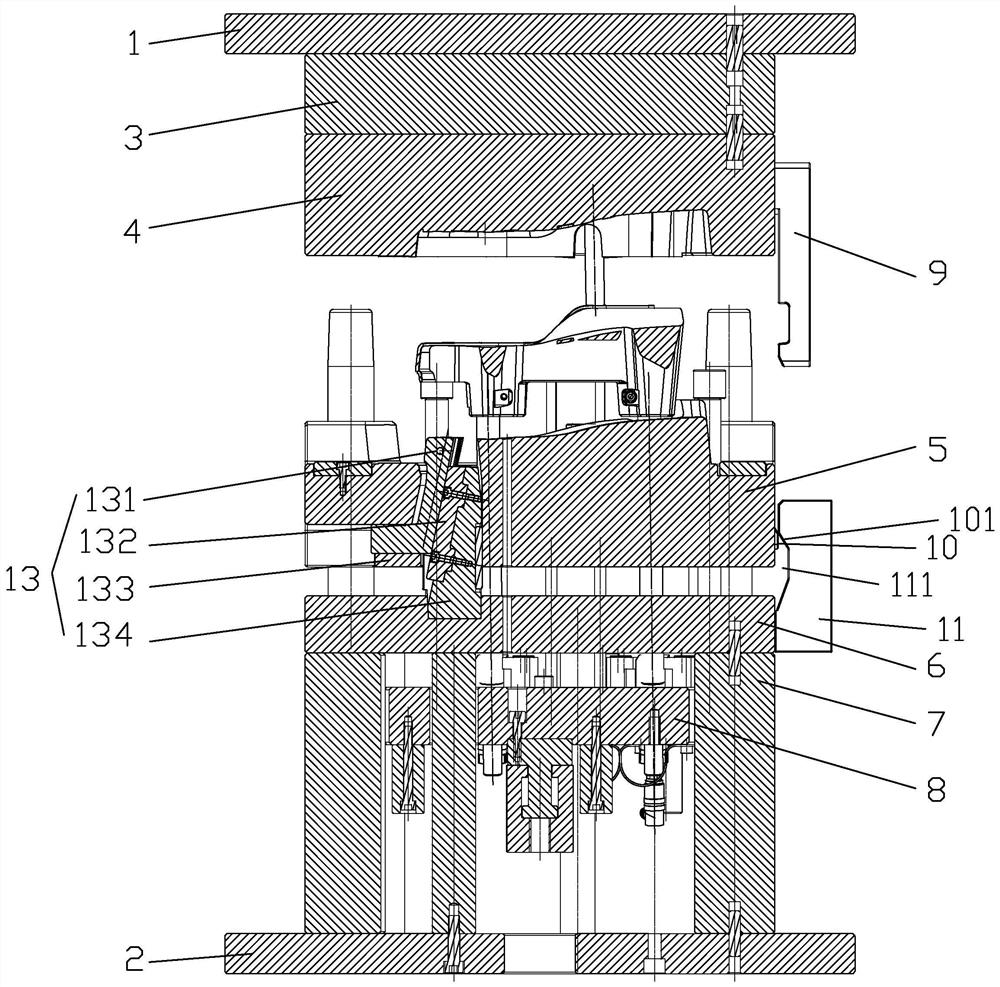

[0027] Such as figure 1 , 2, as shown, an injection mold with an interlocking reverse buckle stripping mechanism, including a mold body, the mold body includes an upper doubler plate 1 and a lower doubler plate 2, and the lower doubler plate 1 is provided with A mold cavity 4, a die foot 7 is arranged above the lower doubler plate 2, a backing plate 6 is arranged on the mold foot 7, and a core 5 is arranged on the backing plate 6; wherein, the mold body is provided with a linkage type reverse buckle demoulding mechanism, The linkage type reverse buckle stripping mechanism includes a linkage type sub-sequence mold opening assembly and an inclined top off the reverse buckle mold ejection assembly 14; The mold opening action is divided into cavity 4-backing plate 6 mold opening and core 5-cavity 4 mold opening; among them, between the cavity 4-backing plate 6 mold opening action and core 5-cavity 4 mold opening action During this period, the inclined ejection and undercutting ej...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap