Preparation method of 3D printing bionic continuous carbon fiber reinforced resin-based composite material

A biomimetic composite material, reinforced resin-based technology, applied in additive processing, 3D object support structure, additive manufacturing, etc., can solve the problems of high production cost and limited reinforcement effect, and achieve improved mechanical strength, wide application range, mechanical Significant effect of strength gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] A method for preparing a 3D printing bionic continuous carbon fiber reinforced resin-based composite material of the present invention, the preparation steps are as follows:

[0047] Step 1: Composition of Raw Materials

[0048] A: The continuous carbon fiber whose specification is 1K is the reinforcing phase;

[0049] B: Based on ABS thermoplastic resin coil suitable for fused deposition 3D printing;

[0050]C: The mass fraction of continuous carbon fiber in the composite material ranges from 5wt.% to 15wt.%;

[0051] Step 2: Equipment debugging

[0052] A: The continuous carbon fiber is ultrasonically treated in a H2SO4 / HNO3 mixture with a volume ratio of 3:1 for 3 hours to improve its interface wettability;

[0053] B: ABS resin was dried at 30°C for 24 hours;

[0054] C: Based on the self-built 3D printer, the ABS resin is printed to the heating platform through the nozzle, and then the continuous carbon fiber is put into the extrusion mechanism, so that it is p...

Embodiment 1

[0068] The bionic layered helical structure was established by analyzing the microstructure of mantis shrimp claws.

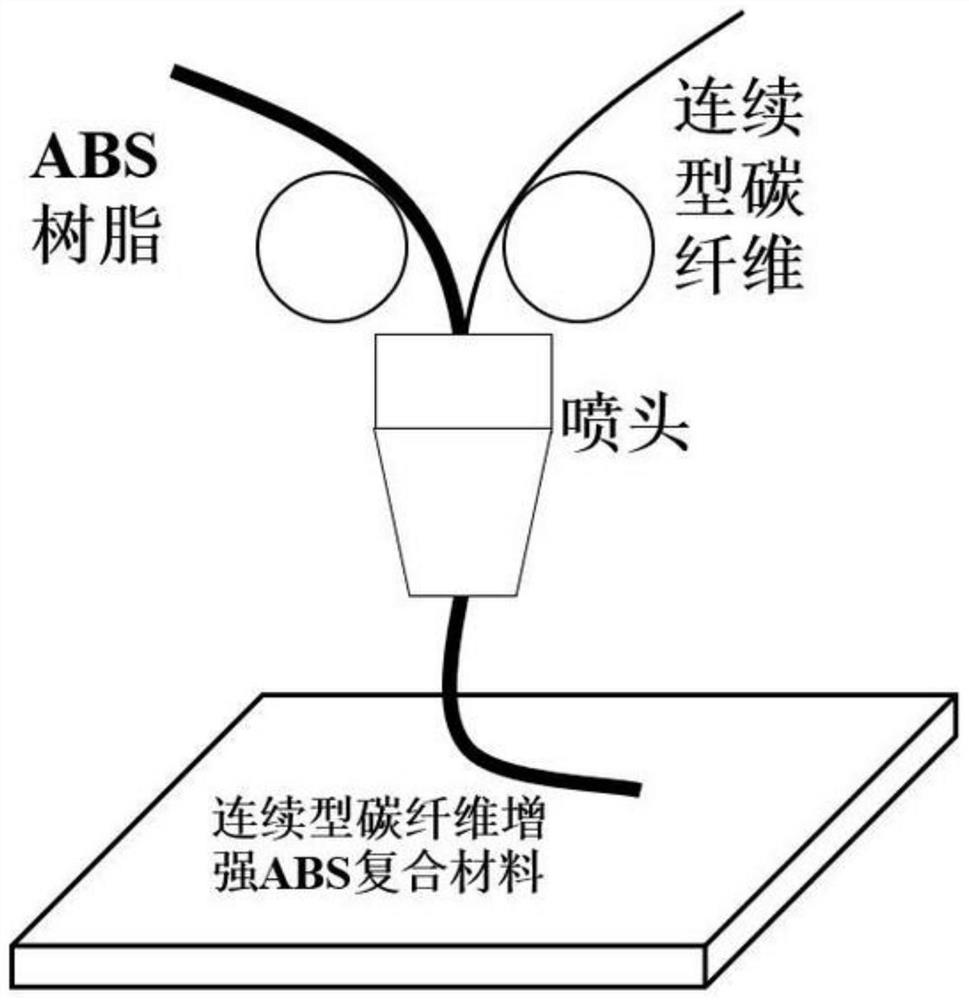

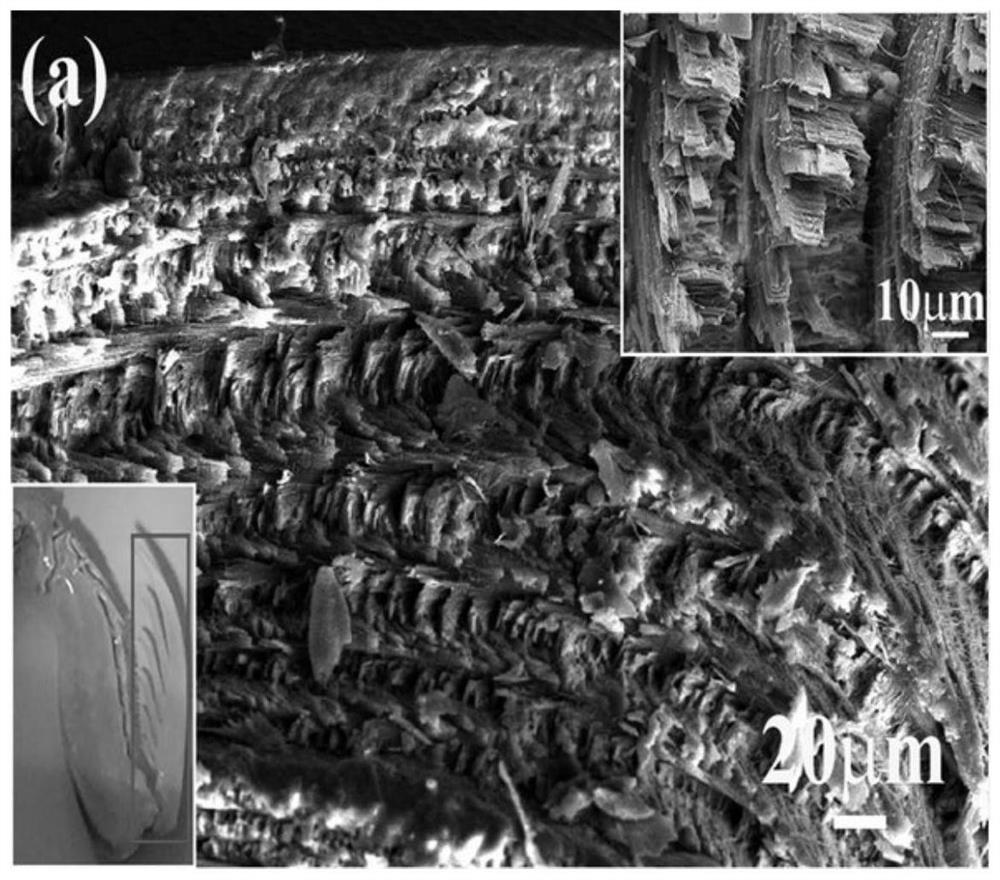

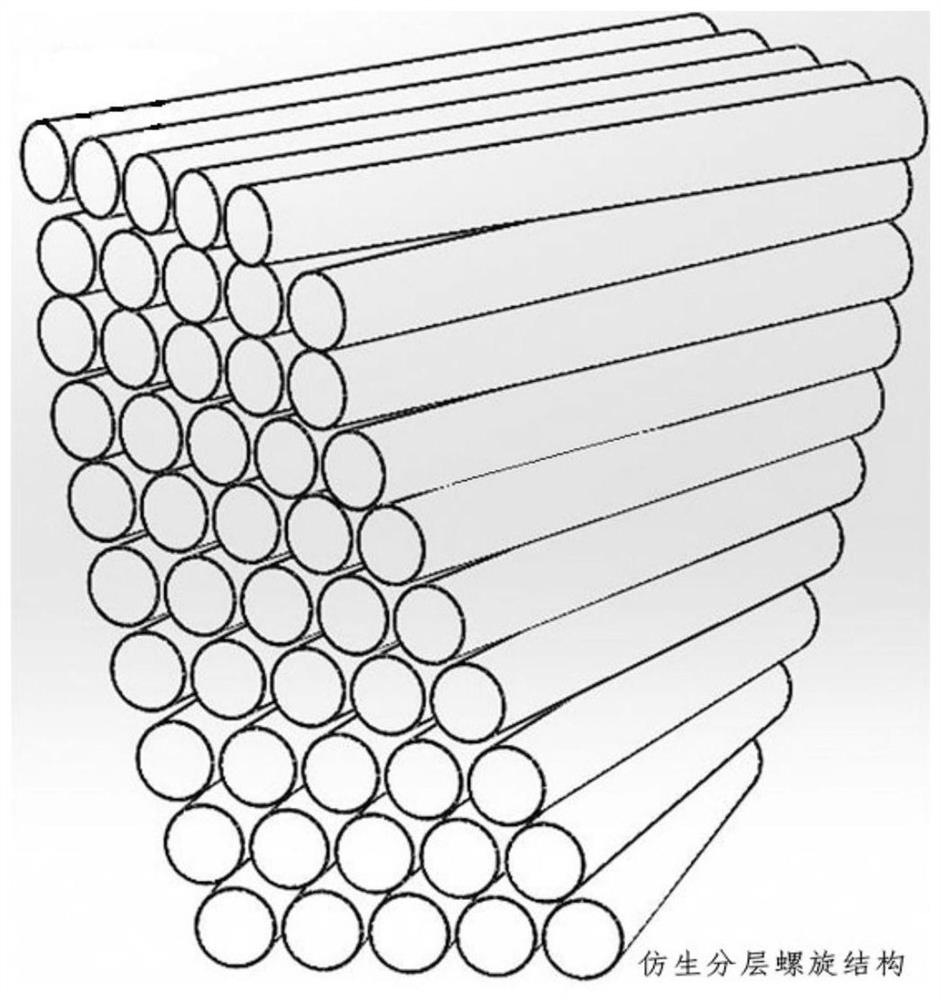

[0069] see figure 1 , figure 2 and image 3 , the present invention adopts self-constructed fused deposition 3D printer, heats the nozzle to reach the melting point of the ABS resin to make it fluid, and with the assistance of the feed gear, the ABS resin wraps the continuous carbon fiber during extrusion and drives which is placed on a heated platform (such as figure 1 shown); the claws of mantis shrimp are composed of multi-layer mineralized fiber thin-layer structures; each thin-layer structure is stacked at a certain angle to form a layered helical structure (such as figure 2 shown); this structure is the basis for the high mechanical properties of the mantis shrimp claw. According to the microstructure characteristics of mantis shrimp claws, combined with 3D printing technology and application characteristics, a image 3 The bionic layered spiral st...

Embodiment 2

[0071] The biomimetic continuous carbon fiber reinforced resin matrix composite was prepared by 3D printing and its mechanical strength was tested.

[0072] see Figure 4 to Figure 11 ,based on Figure 4 The established bionic layered helical structure has successfully prepared bionic continuous carbon fiber reinforced resin matrix composites through 3D printers, such as Figure 4-6 shown. through as Figure 7 The microstructure analysis shown shows that the continuous carbon fibers are completely arranged in the designed layered spiral form, which proves the feasibility of 3D printing method and bionic structure design. combine as Figure 8 , Figure 9 As can be seen from the stress-strain and impact toughness data analysis of the carbon fiber homodirectional arrangement structure sample and the pure ABS resin sample, the bionic continuous carbon fiber reinforced resin matrix composite material has the highest tensile strength and impact toughness, which proves the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com