Nanosheet orderly stacked type macroscopic high-conductivity MXene ribbon-like fiber as well as preparation method and application thereof

A high-conductivity, nanosheet technology for hybrid/electric double-layer capacitor fabrication, hybrid capacitor electrodes, inorganic raw rayon, etc., which can solve problems such as exhibiting limited lateral dimensions, MXene fiber barriers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

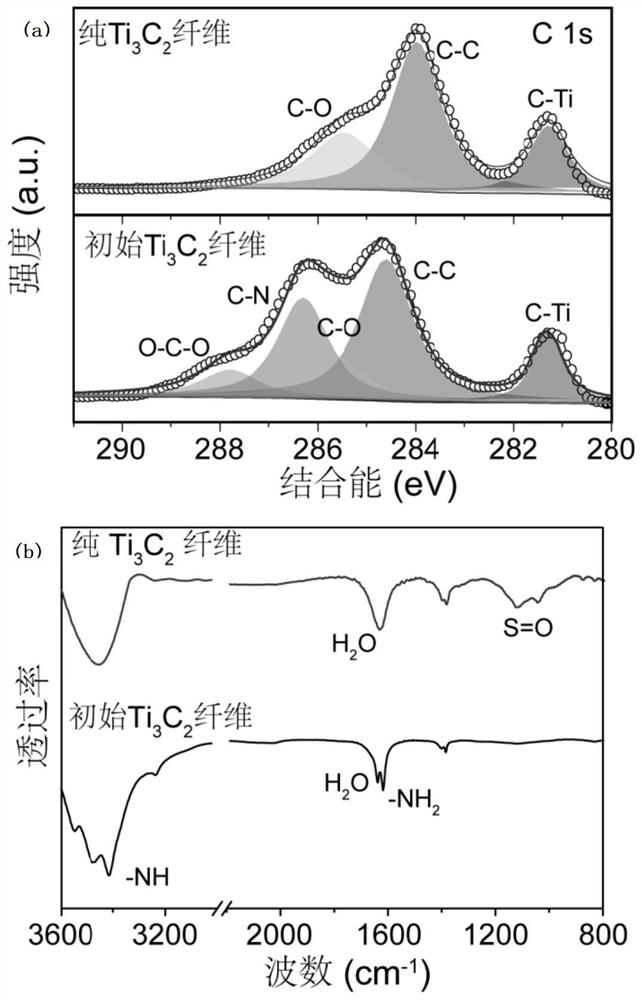

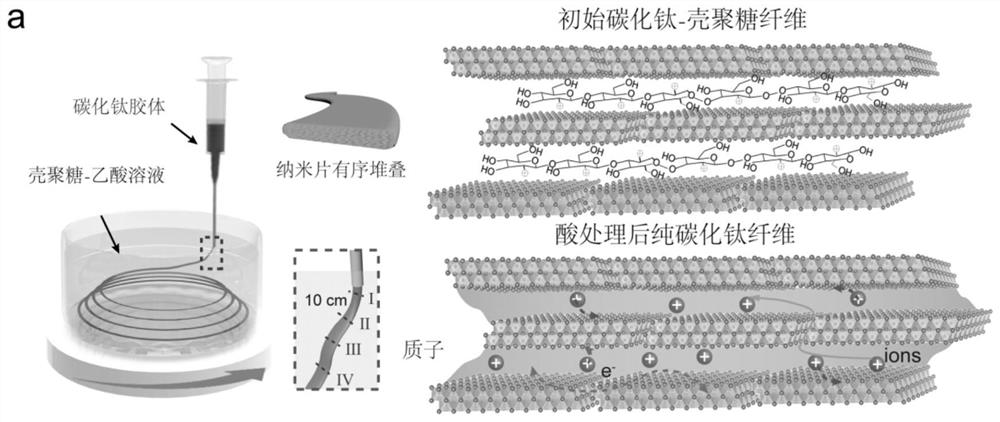

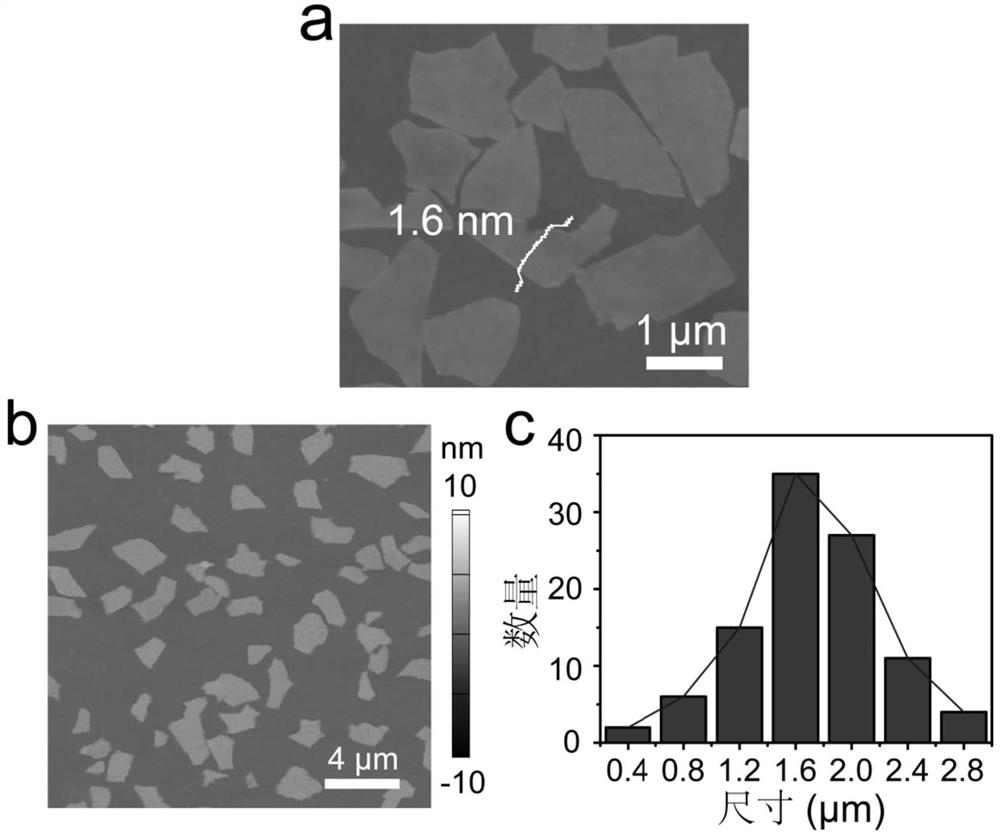

[0053] Preparation of Titanium Carbide Colloidal Aqueous Solution: Ti 3 AlC 2 The powder (1 g) was put into HF solution (10 wt%, 30 mL), stirred for 10 minutes, washed with distilled water for 3 times, and then dried in a vacuum oven at 80 °C for 24 hours. The dried powder was placed in tetramethylammonium hydroxide aqueous solution (25 wt%, 10 mL) and stirred continuously for 24 hours; the resulting suspension was centrifuged at 5000 rpm for 10 minutes, and the bottom precipitate was washed with deionized water and dried; then Redisperse in deionized water, sonicate at room temperature for 15 minutes, centrifuge at 3500rpm for 15 minutes, take the upper suspension and centrifuge at 8000rpm for 15 minutes, and take the lower suspension to obtain an aqueous solution of titanium carbide colloid with a concentration of 20 mg / mL.

[0054] Fill the titanium carbide colloidal aqueous solution into a plastic syringe with a rotating nozzle (conventional stainless steel spinning needl...

Embodiment 2

[0065] A high-performance flexible supercapacitor was obtained by using the orderly stacked macroscopic high-conductivity MXene ribbon fiber of Example 1 as the negative electrode, and assembling it with polyvinyl alcohol-sulfuric acid electrolyte and positive electrode rGO fiber.

[0066] Using the method in Example 1, the titanium carbide colloidal aqueous solution was replaced with a commercially available GO aqueous solution with a concentration of 10 mg / mL (the thickness of the GO sheet was about 1 nm, and the lateral dimension was 3-5 μm), to obtain GO initial fibers, which were then immersed in 90 °C hydroiodic acid (57 wt%) aqueous solution for 5 hours, and then washed with water to obtain rGO fibers as the cathode.

[0067] Under stirring, 1 g of PVA powder was dissolved in 10 mL of distilled water at 90 °C until a clear solution was obtained. After adding 1 g of sulfuric acid and stirring, the clear solution was cooled to room temperature to obtain a polyvinyl alcohol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal size | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com