CTCS-3 level train control system integrated test method

A technology for train control system and integrated testing, which is applied in the fields of operation center control system, railway signal and safety, railway traffic management, etc. It can solve the problems of low efficiency, waste of human resources, actual gap in accuracy and reliability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

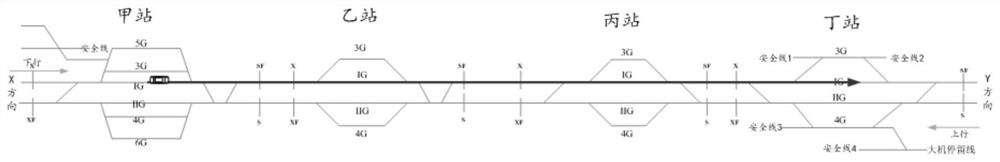

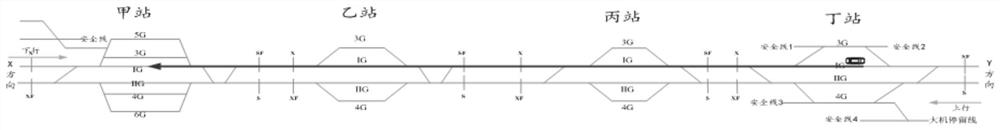

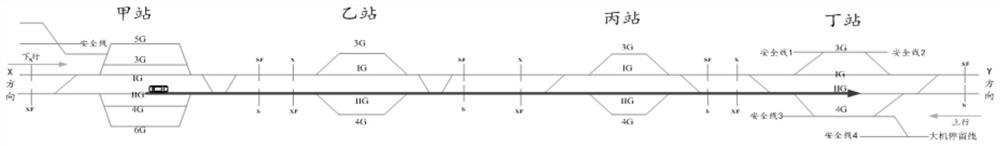

[0061] The following is a further elaboration of the CTCS-3 train control system integration test method described in this application in accordance with the test sequence in conjunction with the accompanying drawings and specific lines:

[0062] [Step 1: Since the high-speed railways are all double-track lines, a 300T EMU will be arranged for the uplink and downlink respectively to carry out the C2 class speed 90Km / h forward and reverse positive line;]

[0063] Test purpose: to collect C2 level main line data, track conditions, capacitance, automatic phase separation, low frequency code sequence, transponder message and link test;

[0064] Test conditions: (1) The 300T moving inspection car needs to turn off the MT power supply when controlling the car with C2 train control on-board equipment. (2) Each station arranges the incoming and outgoing routes according to the test sequence, and each station (station) needs to open the entry and exit signals after the driver's joint c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com