Automatic sealing strip attaching integrated equipment

A strip-integrated, sealing-strip technology, applied in the direction of winding strips, sending objects, rollers, etc., can solve the problems of high labor intensity and low production capacity of door leaves, and achieve the effects of improving efficiency, high compatibility, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to better understand the technical solution of the present invention, the following will be described in detail through specific examples:

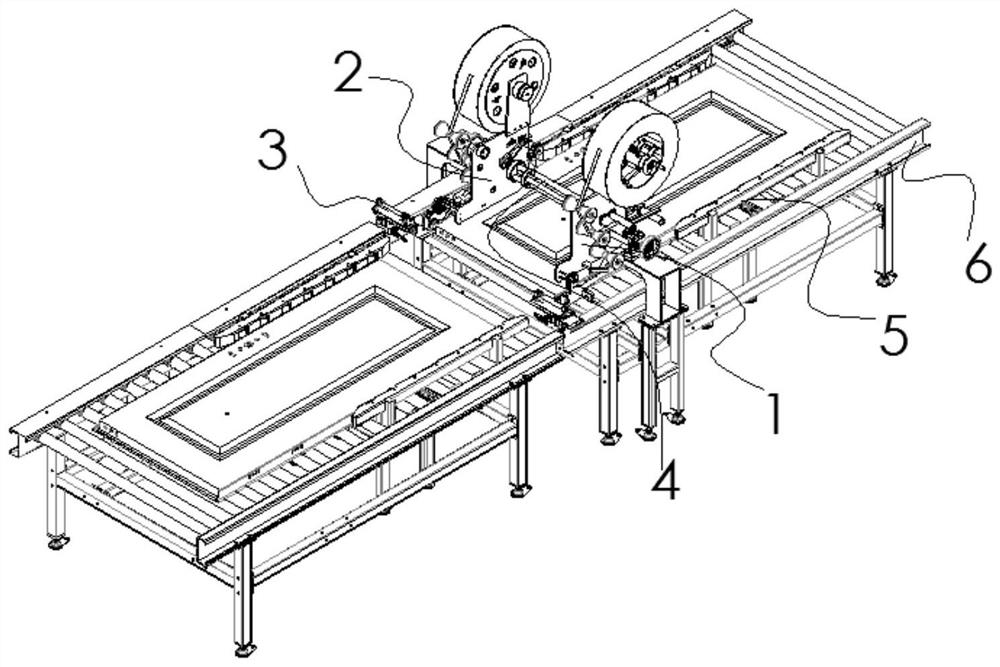

[0027] see figure 1 , an integrated device for automatically attaching sealing strips according to the present invention consists of an automatic sealing strip attachment mechanism 1 on the hinge side, an automatic sealing strip attachment mechanism 2 on the keyhole side, a sealing strip clamping and cutting device 3, a bracket width adjustment mechanism 4, and a pair of The middle clamps the facade mechanism 5 and the facade conveying roller line body 6 to form.

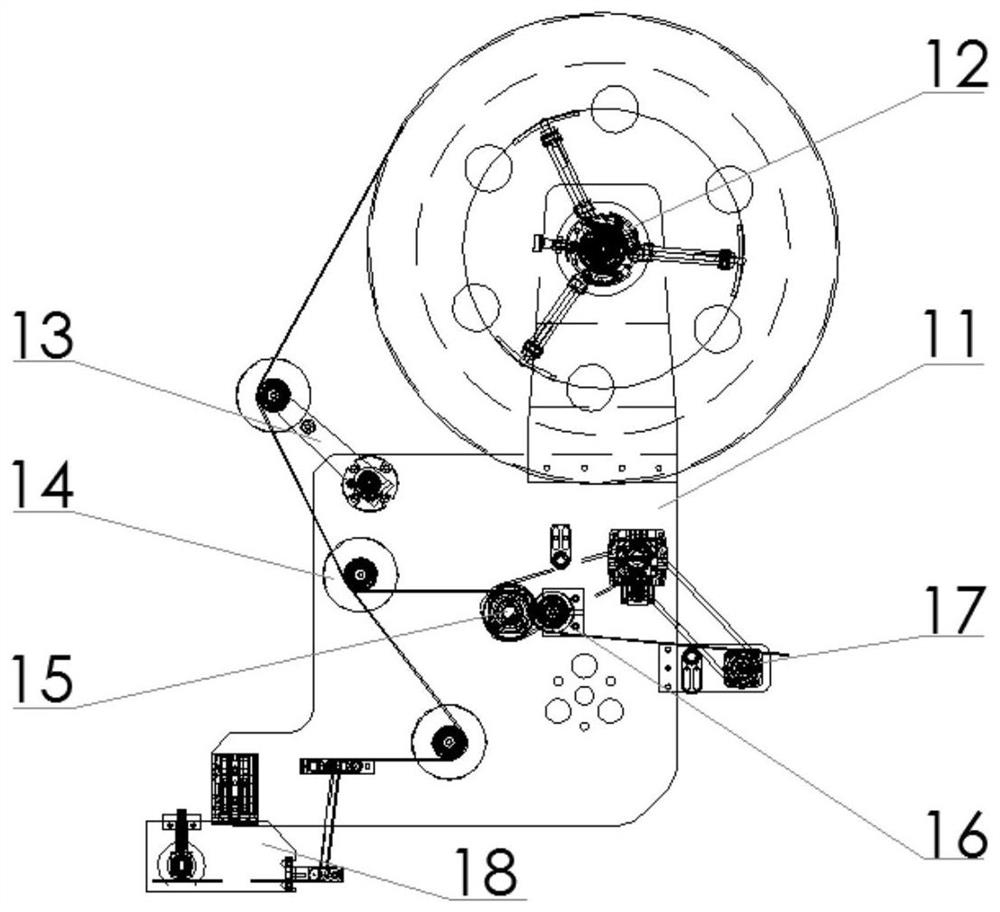

[0028] see figure 2 , the coil material with a diameter of 500 mm in the sealing strip mechanism 1 that is automatically attached to the hinge side is placed on the sealing strip coil placing mechanism 12, and the internal structure of the sealing strip coil placing mechanism 12 contains a screw assembly. After manually placing the coil material, turn the hand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com