Preparation method of pentamethylindane

A technology of pentamethylindene and indane, which is applied in the field of preparation of pentamethylindane, which can solve the problems of low synthesis yield, influence on reaction effect and low catalytic efficiency of musk musk, achieve excellent catalytic performance and improve purity , the effect of increasing the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

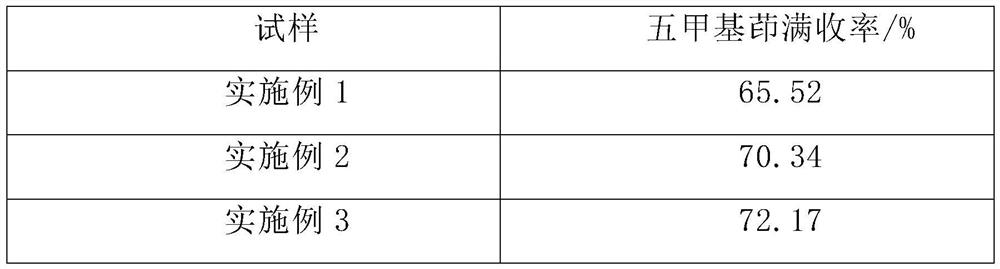

Embodiment 1

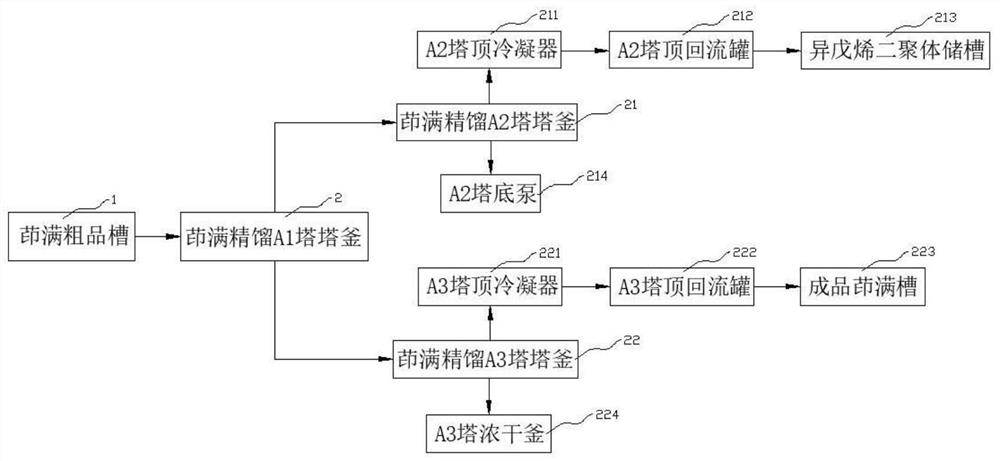

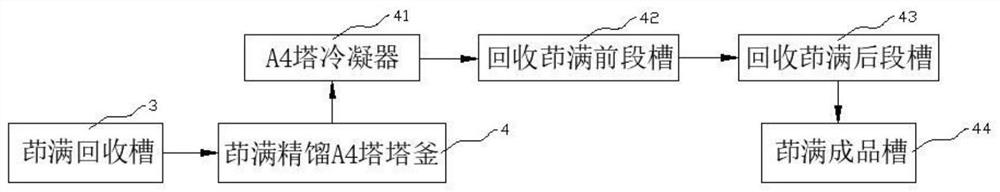

[0030] A preparation method of pentamethylindane, the specific method is: mix α-methylstyrene and isopentene evenly in a molar ratio of 1:0.75, then drop the mixed solution into the reaction kettle, the dropping time is 20h, Put phosphomolybdic acid into the reaction kettle, the molar ratio of phosphomolybdic acid to isopentene is 1:0.85, the pressure inside the kettle is normal pressure, keep the temperature at 30°C, keep warm for 2 hours, and react to obtain the crude product of pentamethylindane , use the indane rectification unit to rectify the indane crude product to obtain the pentamethylindane finished product.

Embodiment 2

[0032] A preparation method of pentamethylindane, the specific method is: mix α-methylstyrene and isopentene evenly in a molar ratio of 1:0.75, then drop the mixed solution into the reaction kettle, the dropping time is 20h, Put cross-linked polystyrene-loaded phosphomolybdic acid into the reactor, the molar ratio of cross-linked polystyrene-loaded phosphomolybdic acid to isopentene is 1:0.85, the pressure in the kettle is normal pressure, keep the temperature at 30°C, keep the temperature After reacting for 2 hours, the crude product of pentamethylindane was obtained through the reaction, and the crude product of indane was rectified by using an indane rectification unit to obtain the finished product of pentamethylindane. ;

[0033] Among them, the loading method of cross-linked polystyrene loaded phosphomolybdic acid is: 1) disperse the cross-linked polystyrene powder with a cross-linking degree of 5 into boiling water, add phosphomolybdic acid after stirring evenly, polyst...

Embodiment 3

[0034] Embodiment 3 is different from Embodiment 2 in that,

[0035] The degree of crosslinking of the crosslinked polystyrene powder is 7.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap