Blending method of Australian coking coal with G value of less than 75

A technology of G value and coking coal, applied in the field of coal blending and coking, can solve the problems of increasing production cost, unable to use coking coal, etc., and achieve the effect of reducing coal blending, low coal blending cost and excellent coke quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

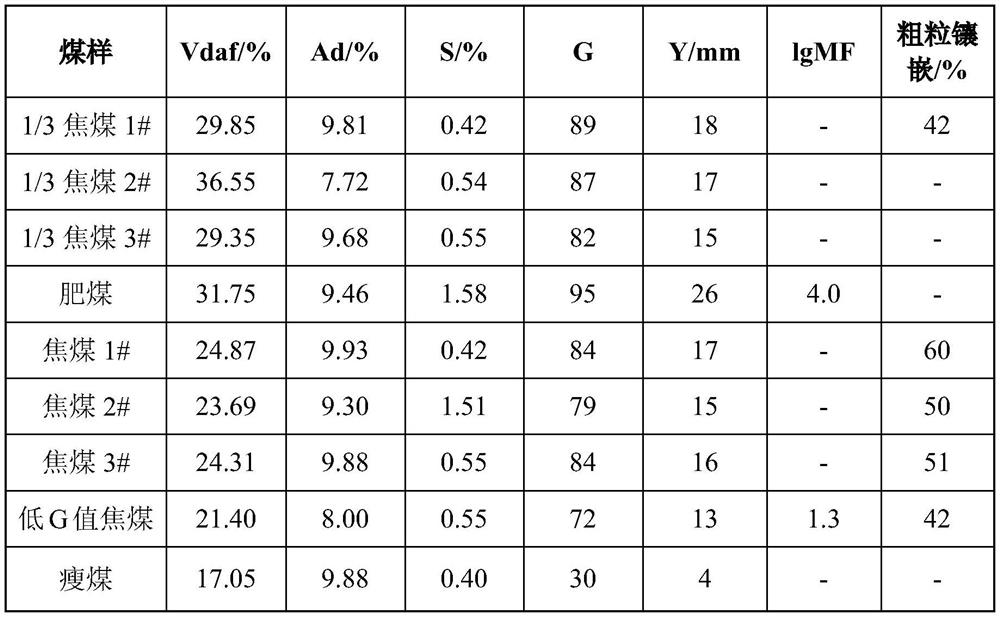

[0053] Coal 1, Coke 2, Coke 3, 1 / 3 Coke 1, 1 / 3 Coke 2, 1 / 3 Coke 3, fat coal, and Australian coking coal with low G value, the coal quality analysis data of lean coal in a coking plant are shown in Table 1 .

[0054] Table 1 Experimental data of single coal

[0055]

[0056]Step 2: Analyze the coking performance of coking coal and 1 / 3 coking coal single coal.

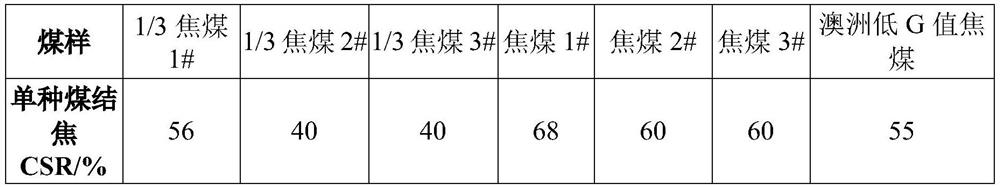

[0057] Table 2 Comparison of coking CSR of each single coal

[0058]

[0059] (The coking of the above single coal is smelted in a 2 kg experimental coke oven, and each laboratory can analyze it according to the specific small coke oven).

[0060] Rank coking coal and 1 / 3 coking coal single coal coking performance:

[0061] CSR 焦1 >CSR 焦2 ≈CSR 焦3 >CSR 低G值焦煤 ;

[0062] CSR 1 / 3焦1 >CSR 低G值焦煤 >CSR 1 / 3焦3 ≈CSR 1 / 3焦2 Wherein, coke 1 represents coking coal 1#, coke 2 represents coking coal 2#, coke 3 represents coking coal 3#, 1 / 3 coke 1 represents 1 / 3 coking coal 1#, 1 / 3 coke 2 represents 1 / 3 coking coal 2#, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volatile matter | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com