Extra-thick anti-seismic fire-resistant steel plate with yield strength of 390MPa and manufacturing method thereof

A technology of yield strength and manufacturing method, which is applied in the field of anti-seismic refractory steel plate and its manufacturing, can solve the problems of high cost and no hot-rolled extra-thick refractory steel, etc., and achieve the goal of improving high-temperature performance, excellent comprehensive performance, and improving performance pass rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

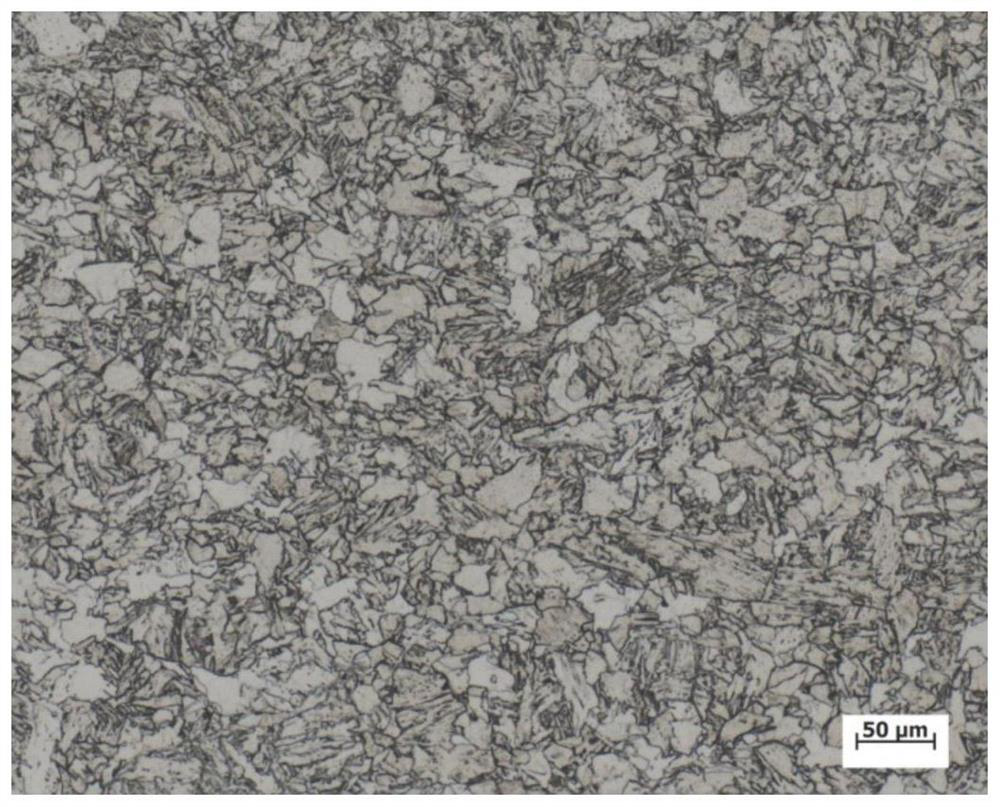

Embodiment 1

[0020] The yield strength 390MPa grade 100mm extra-thick anti-seismic refractory steel plate of Example 1 has the mass percentages of each element in its chemical composition: C: 0.048%, Si: 0.31%, Mn: 0.55%, P: 0.008%, S: 0.003%, Cr: 0.38%, Mo: 0.17%, Nb: 0.037%, V: 0.061%, Ti: 0.015%, Al: 0.031%, N: 0.004%, and the balance is Fe and unavoidable impurity elements.

[0021] Its manufacturing method comprises the following process steps:

[0022] Steelmaking and continuous casting process: target sulfur content of molten iron is 0.010% after desulfurization; converter smelting adopts high-blown low-drawing method for dephosphorization, and converter taps steel as slag; refining adopts white slag operation, white slag retention time is 19 minutes, and the total refining time is 46 minutes. During the process, alloys are added sequentially in the order of Ti, Cr, Mo, Nb and V to adjust the composition of molten steel to the target composition; the vacuum treatment is kept for 22 ...

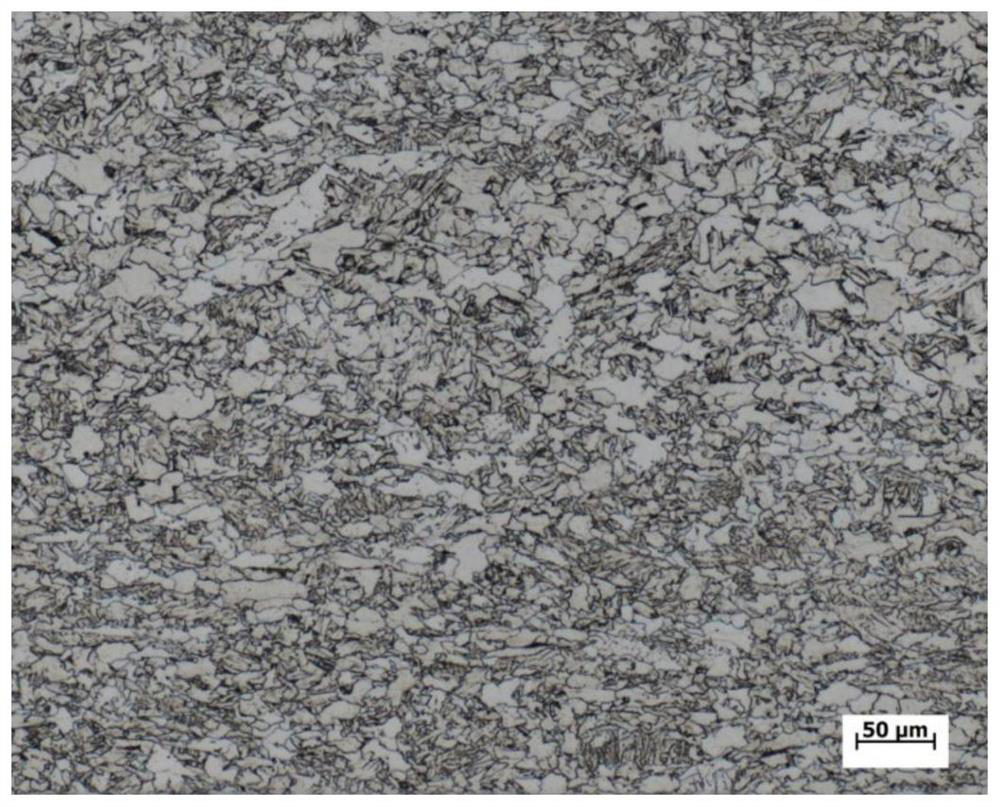

Embodiment 2

[0026] The yield strength 390MPa grade 100mm extra-thick anti-seismic refractory steel plate of Example 2 has the mass percentages of the elements of the chemical composition: C: 0.062%, Si: 0.42%, Mn: 0.76%, P: 0.010%, S: 0.002%, Cr: 0.45%, Mo: 0.13%, Nb: 0.032%, V: 0.065%, Ti: 0.022%, Al: 0.023%, N: 0.004%. The balance is Fe and unavoidable impurity elements.

[0027] Its manufacturing method comprises the following process steps:

[0028] (1) The target sulfur content after desulfurization of molten iron is 0.008%; converter smelting adopts high-blown low-drawing method for dephosphorization, and converter taps steel as slag; refining adopts white slag operation, white slag retention time is 22 minutes, and the total refining time is guaranteed to be 40 minutes. Add alloys in the order of Ti, Cr, Mo, Nb and V to adjust the composition of molten steel to the target composition; hold the vacuum treatment for 20 minutes; after the vacuum treatment, perform the treatment of fe...

Embodiment 3

[0032] The steel plate of embodiment 3, its chemical composition each element mass percent is: C: 0.071%, Si: 0.28%, Mn: 0.46%, P: 0.009%, S: 0.004%, Cr: 0.53%, Mo: 0.16%, Nb: 0.044%, V: 0.041%, Ti: 0.017%, Al: 0.019%, N: 0.004%. The balance is Fe and unavoidable impurity elements.

[0033] Its manufacturing method comprises the following process steps:

[0034] (1) The target sulfur content after desulfurization of molten iron is 0.011%; converter smelting adopts high-blowing and low-drawing method for dephosphorization, and converter is tapped as slag; refining adopts white slag operation, white slag retention time is 16 minutes, and the total refining time is guaranteed to be 40 minutes. Add alloys in sequence according to the order of Ti, Cr, Mo, Nb and V, adjust the composition of molten steel to the target composition; keep the time of vacuum treatment for 25 minutes; after the vacuum treatment, perform the treatment of feeding pure calcium wire; the temperature of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com