Well sealing method for relief well on large bottom plate of foundation pit

A technology for decompression wells and foundation pits, which is applied in excavation, infrastructure engineering, protection devices, etc., can solve the problems of unsatisfactory well sealing effect, high construction difficulty, complicated construction process, etc., and achieves good well sealing effect and construction difficulty. Reduced, clear process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] The present invention comprises the steps:

[0032] 1.1. Preparations before closing the well:

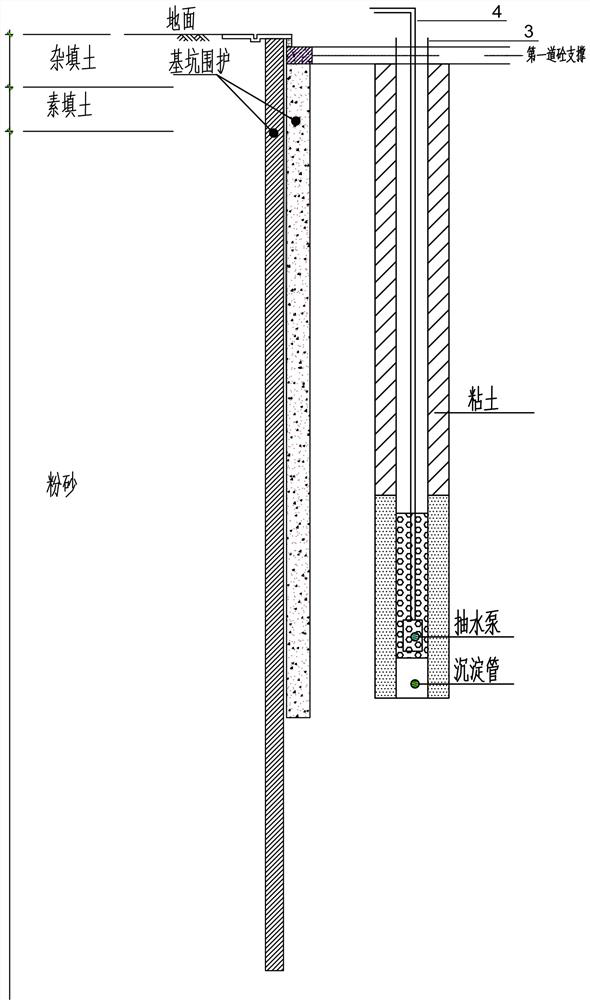

[0033] refer to figure 1 , 1.1.1, along with the decline of foundation pit water level, carry out excavation of foundation pit, finish the first concrete support of foundation pit; The suction pipe 4, the relief well continues to maintain the pumping condition.

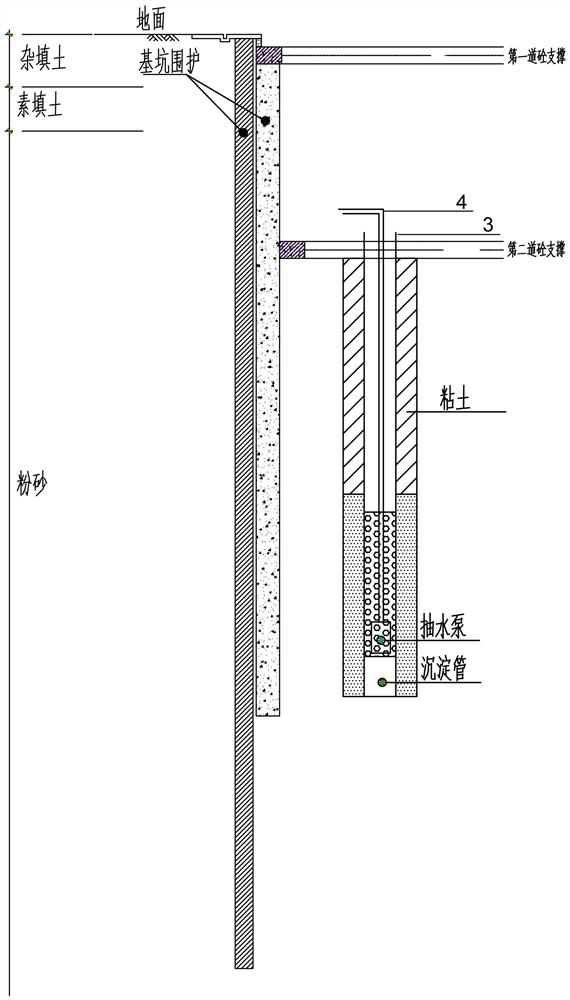

[0034] refer to figure 2 , 1.1.2, continue to implement the excavation of the foundation pit, complete the second concrete support of the foundation pit; cut off the relief well pipe 3 above the excavation surface, retain the original suction pipe 4 in the relief well pipe 3, reduce Kill the well and continue to maintain the pumping condition;

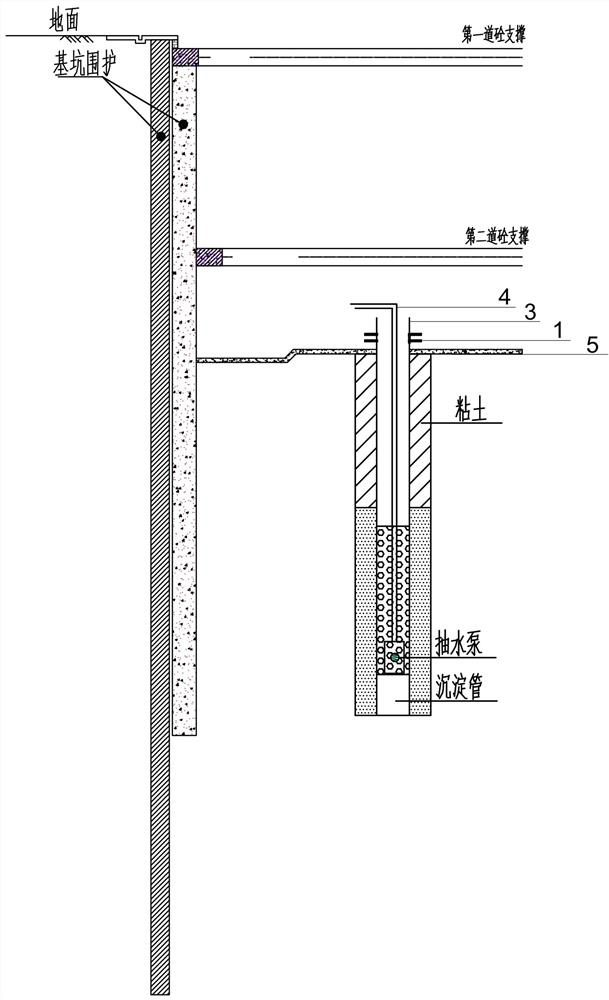

[0035] Repeat the above steps 1.1.1 and 1.1.2 until the last concrete support of the foundation pit is completed; cut off the well pipe 3 of the relief well above the excavation surface, and keep the well pipe 3 of the relief well below the plane elevation of the large ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com