Energy-saving, purifying and environment-friendly system for drilling fluid

A drilling fluid and environmental protection technology, applied in the field of drilling fluid energy saving, purification and environmental protection systems, can solve the problems affecting the working performance and working life of the bottom hole power machine, waste of production materials, barite powder deposition, etc. Risk, guarantee timeliness and accuracy, effect of rational structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

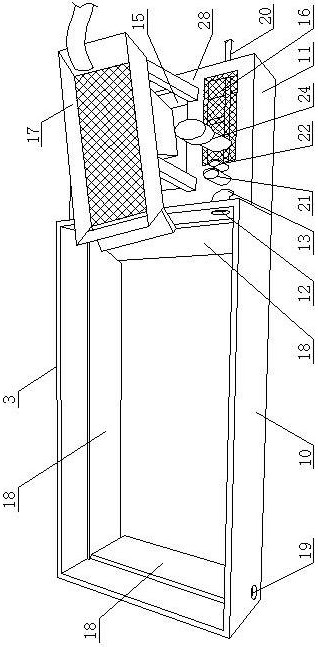

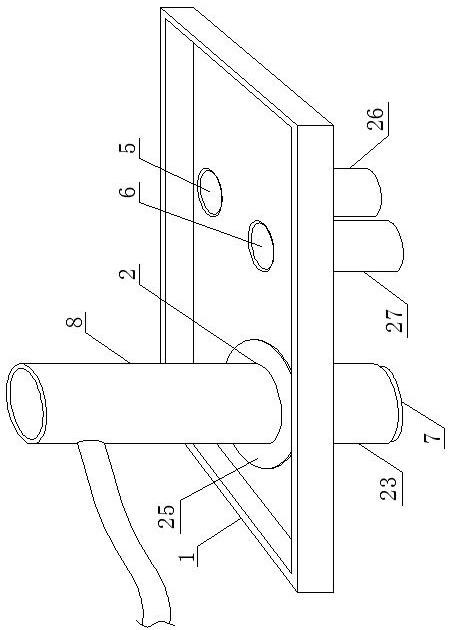

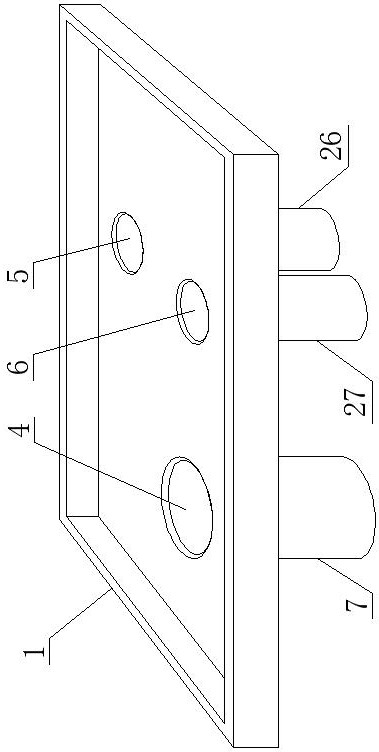

[0025] The drilling fluid energy-saving purification and environmental protection system of the present invention includes a drilling fluid isolation collection device 1, a surface wellhead device 2 and a wellhead energy-saving purification device 3. The drilling fluid isolation collection device 1 is a tank with an open top, and its bottom sits on the ground. Hole I4, hole II5 and hole III6 are opened on the bottom of the tank of drilling fluid isolation and collection device 1, and hole I4, hole II5 and hole III6 are respectively connected to the wellhead, rat hole 26 and mouse hole 27 in the ground. Correspondingly, according to the different construction methods and construction periods of different drilling rig models, drilling fluid isolation and collection devices 1 of different materials and shapes can be used. The drilling fluid isolation and collection device 1 can collect and utilize scattered drilling fluid, The drilling fluid produced when the rat hole 26 and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com