Method and appts. for mfg. disc-shaped recording medium

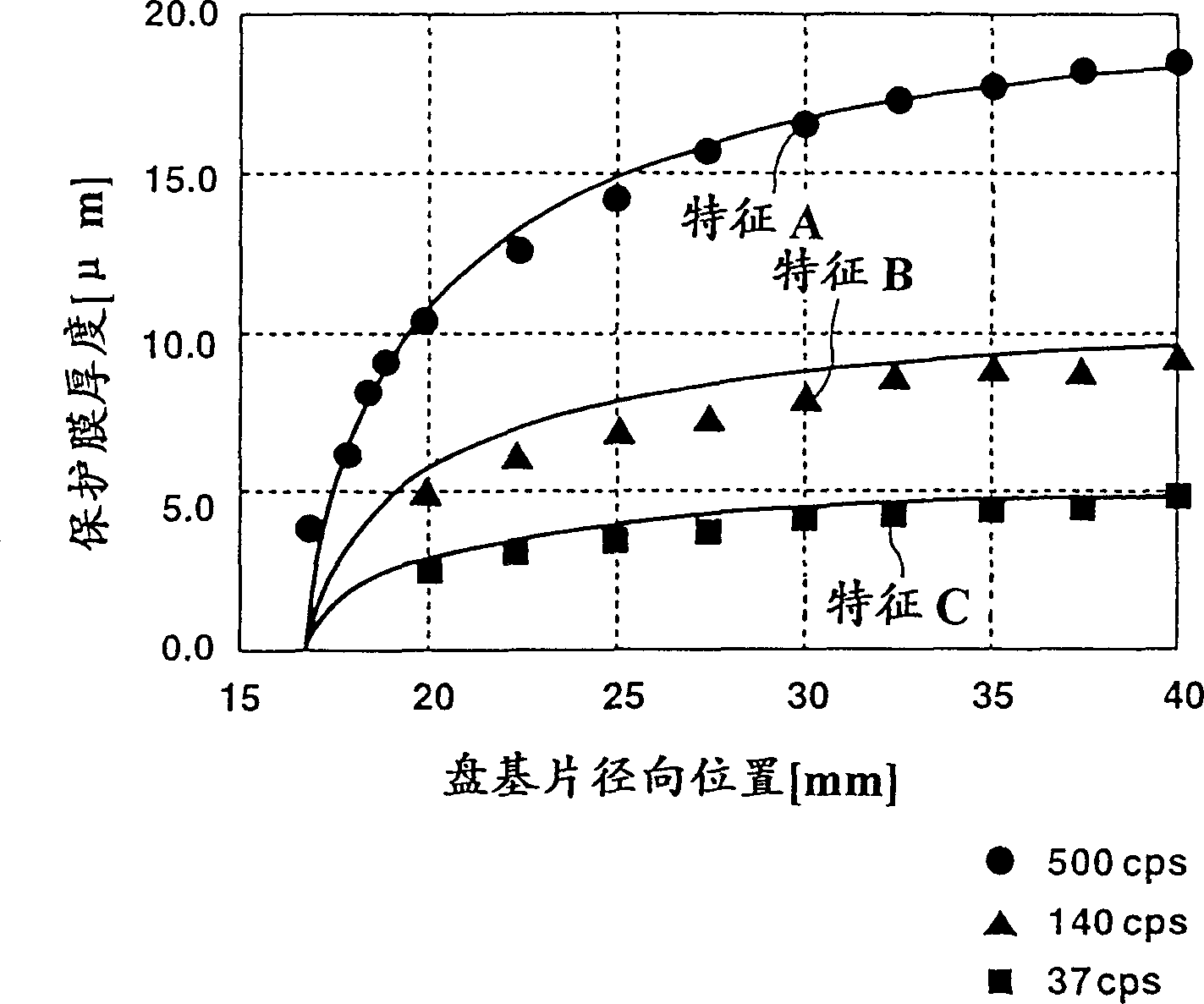

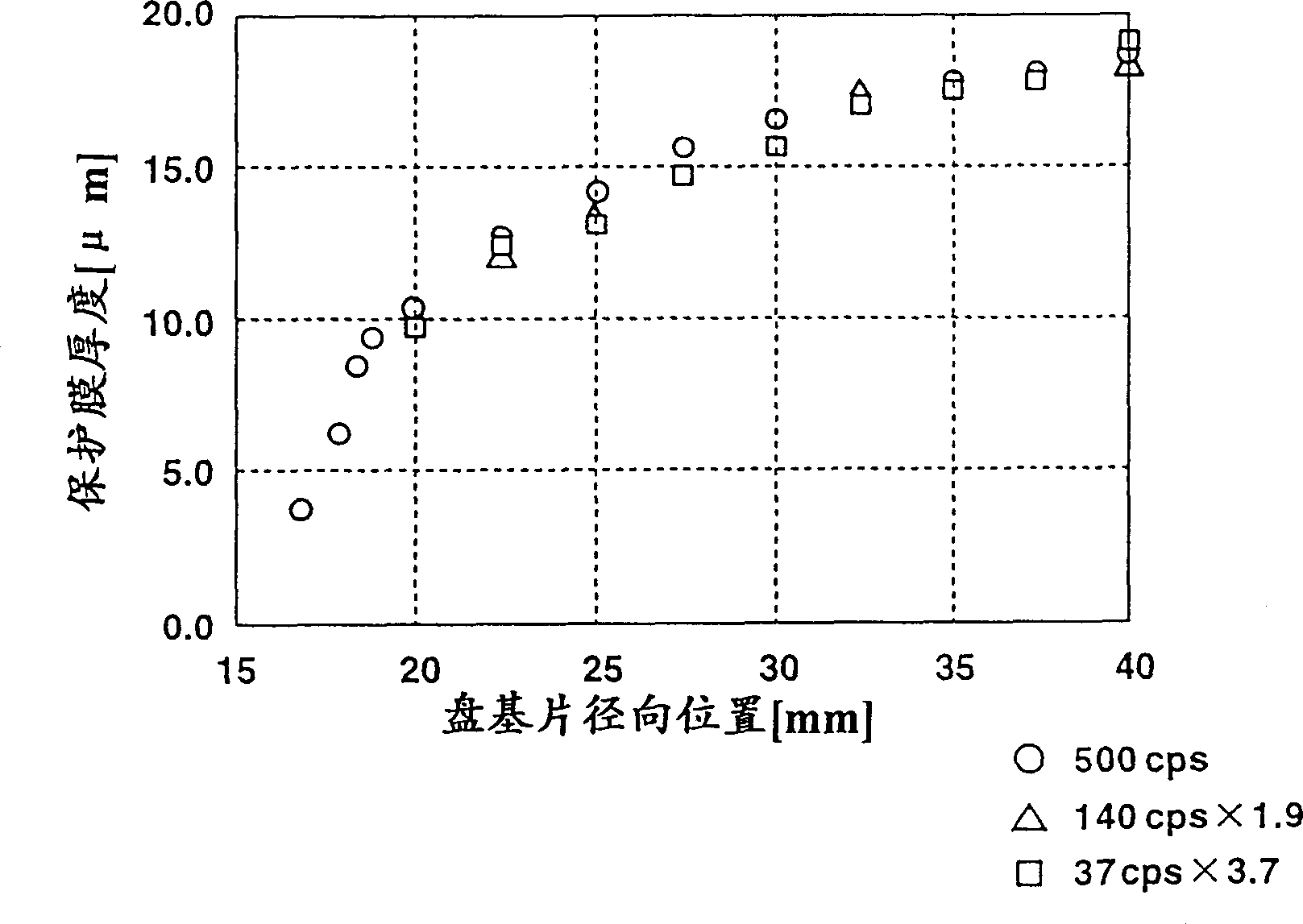

A recording medium and disk-shaped technology, which is applied in the field of manufacturing disk-shaped recording media such as magneto-optical disks, can solve problems such as fluctuations in the thickness of the protective film, achieve uniform thickness of the protective film, eliminate film thickness differences between the inner and outer edges of the recording medium, and stabilize The effect formed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 approach

[0116] A second embodiment of the disc-shaped recording medium according to the present invention will be described below.

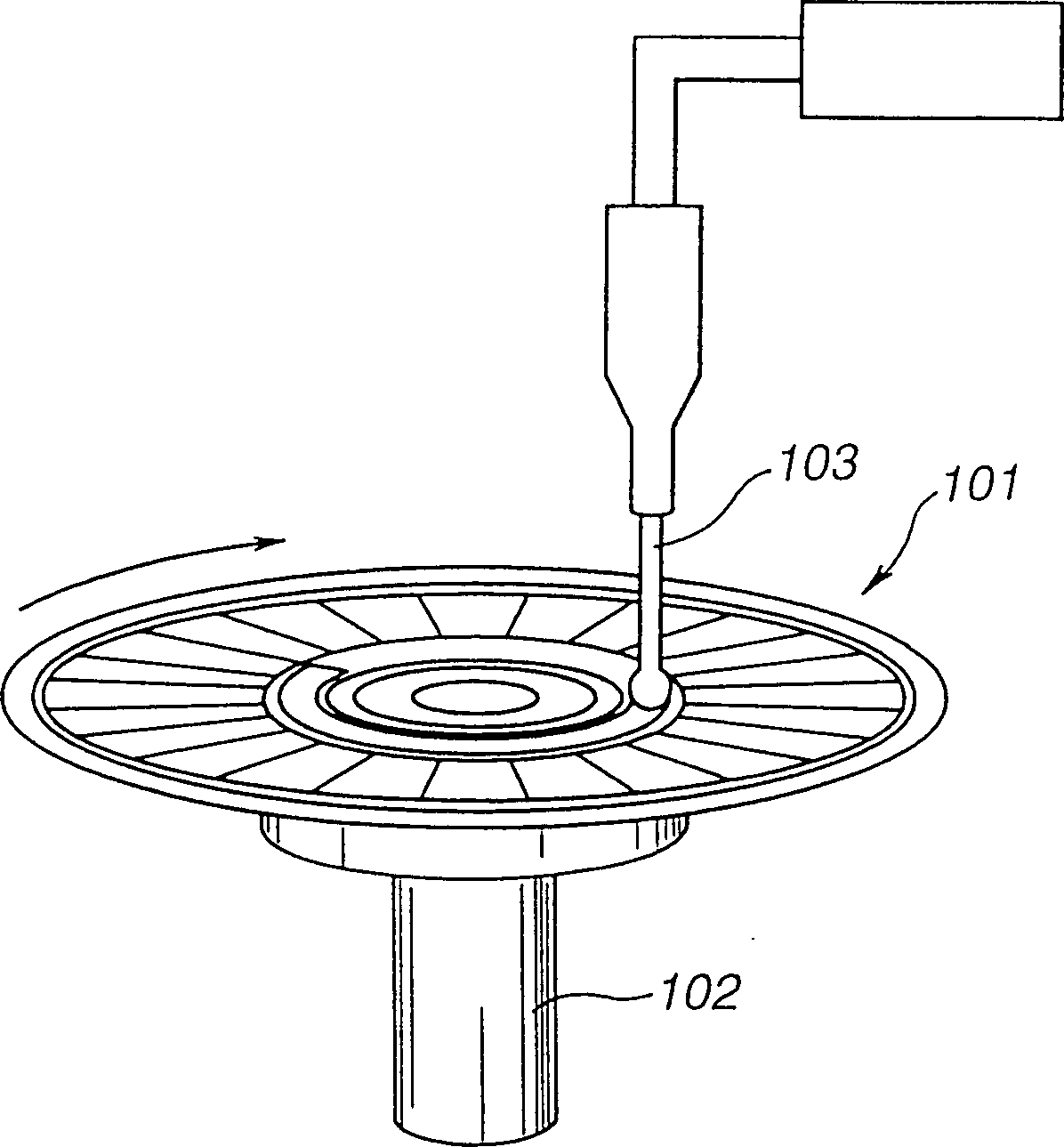

[0117] refer to Figure 5 to Figure 7 , the manufacturing apparatus of a disc-shaped recording medium includes a rotating shaft 31 having a flange 33 having a substantially annular planar configuration on an end 31a thereof, the end 31a supporting a disc substrate 32 of the disc-shaped recording medium. The rotating shaft 31 has a central groove 34, which is opened on the end 31a. The disk-shaped recording medium manufacturing equipment also includes a rotating disk unit 38 , the disk body 36 of which covers the central hole 35 on the disk substrate 32 of the disk-shaped recording medium, and the central shaft 37 inserted into the groove 34 of the rotating shaft 31 .

[0118] The rotating shaft 31 is substantially cylindrical in shape and has a flange 33 at its end 31a. The flange 33 is provided not at the top end of the end 31 a but slightly below the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com