Deslagging device of tunnel boring machine and tunnel boring machine

A technology of tunnel boring machine and tunnel, which is applied in tunnels, mining equipment, earthwork drilling and mining, etc. It can solve the problems of large slag discharge dead angle, affecting tunneling efficiency, large slag discharge dead angle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

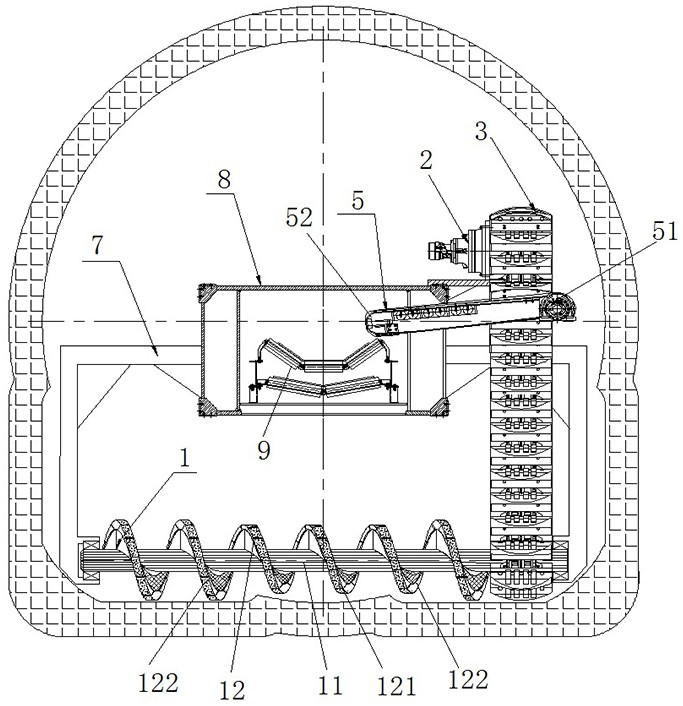

[0064] The tunnel boring machine in this embodiment is mainly used for processing and excavating door-hole type tunnels. The basic structure of the tunnel boring machine is the same as that of the gate-hole type tunnel boring machine disclosed in the application publication number CN112727483A, and will not be described in detail here. .

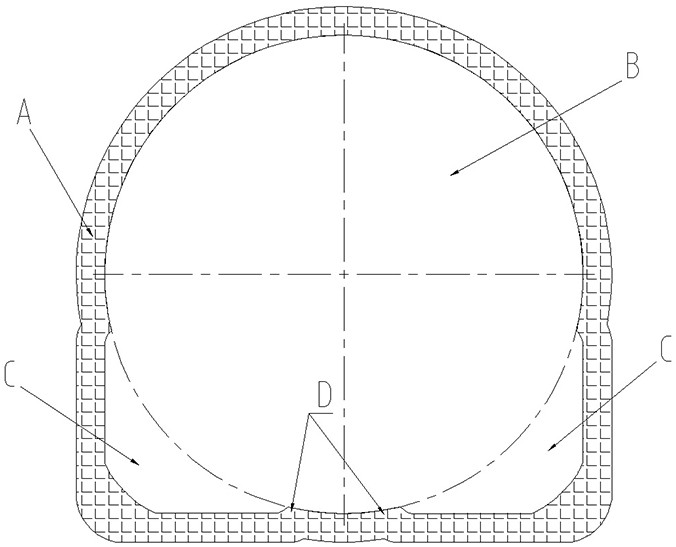

[0065] Here, the tunnel boring machine as a whole includes a main beam extending along the front-to-back direction, and a circular cutter head is arranged at the front end of the main beam to excavate a circular first tunnel section, such as figure 1 In area B in the front shield, auxiliary cutter heads are respectively provided on the inner side of the front shield and on both sides of the bottom of the circular cutter head. The corner area C is excavated, and then the second tunnel section A in the shape of a doorway is formed through the cooperation of the main cutterhead and the auxiliary cutterheads at the bottom of both sides, that is,...

specific Embodiment 2

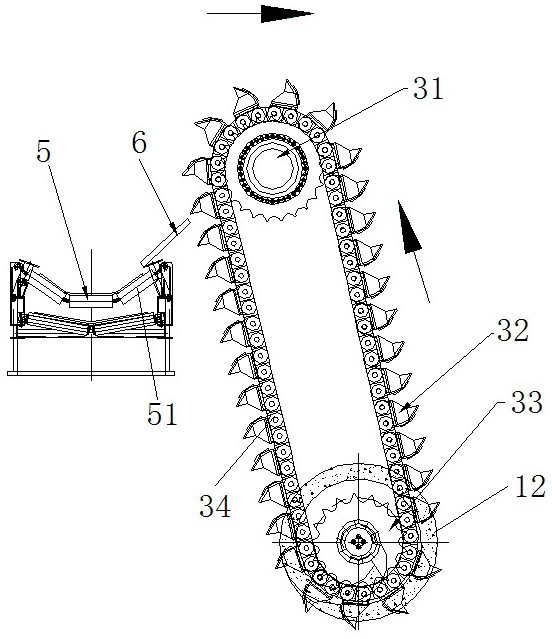

[0078]The main difference between it and Embodiment 1 is that in Embodiment 1, the scraper conveying mechanism includes an upper sprocket, a lower sprocket and a transmission chain. In this embodiment, the scraper conveying mechanism can also adopt the structure of the slag collecting device disclosed in the application publication number CN112727483A, which can include a single driving sprocket and an annular ring arranged around the driving sprocket. Transmission chain, at this moment, the central axis of driving sprocket is parallel with the central axis of central drive shaft, and bucket-shaped hanging plate can be set on the endless transmission chain, satisfy the transshipment of slag.

[0079] Of course, at this time, in order to ensure the normal operation of the screw conveying structure, a separate driving device needs to be provided corresponding to the central drive shaft to drive the central drive shaft to rotate with the helical blades.

specific Embodiment 3

[0081] The difference between it and Embodiment 1 mainly lies in that in Embodiment 1, the lower sprocket is coaxially connected with the central drive shaft, and the central drive shaft is driven to rotate by the corresponding lower sprocket, sharing a motor. In this embodiment, driving motors can be independently configured corresponding to the scraper conveying mechanism and the screw conveying structure, so as to satisfy normal operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com