Photoetching hot area detection method based on federal personalized learning

A detection method and hot zone technology, applied in the field of machine learning, can solve problems such as data incompatibility, poor performance, and difficulty in achieving detection accuracy, and achieve the effects of overcoming data heterogeneity, improving accuracy, and realizing privacy protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

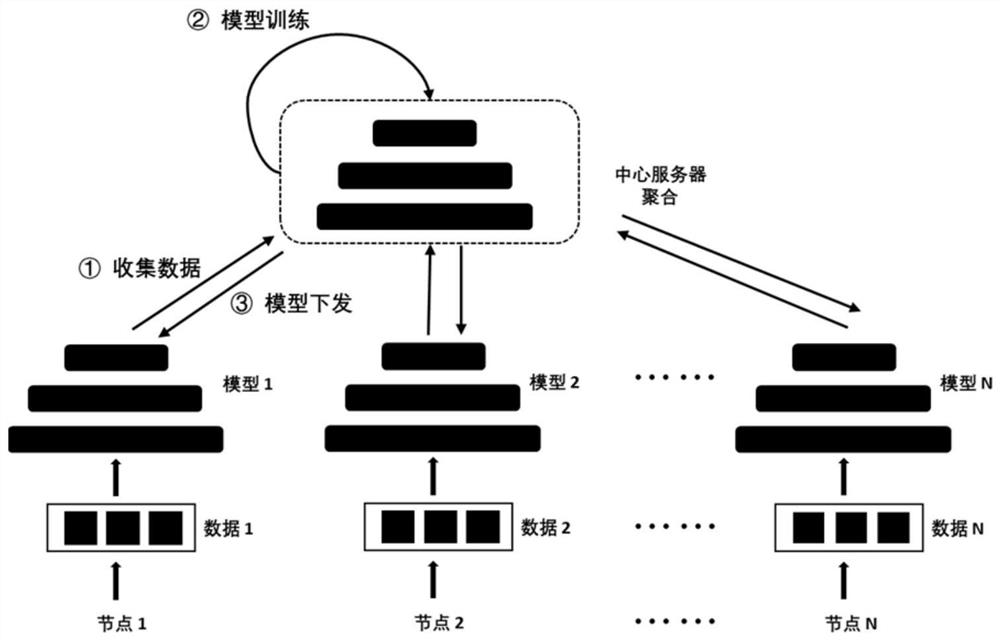

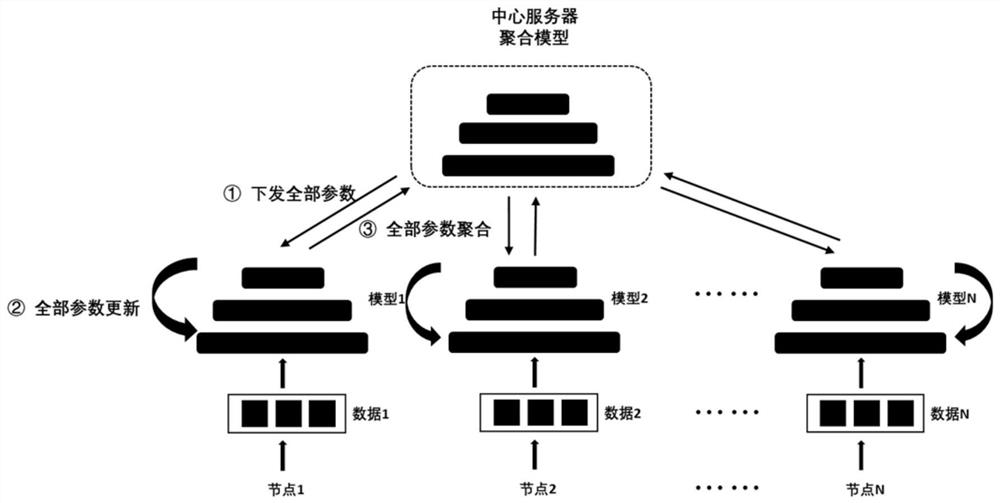

[0051] When photolithographic adjustments are made to IC design layouts, certain layouts are less robust to such adjustments and are more likely to cause open or short failures during fabrication, such failure-prone regions are defined as Photolithography hot zone. The main goal of lithography hot spot inspection is to improve the inspection accuracy as much as possible and minimize the inspection error rate. Training a lithographic hotspot detection model with good performance usually requires a large amount of data. However, due to data privacy, factories with lithographic hotspot data will not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com