Konjac spaghetti processing technology

A pasta and processing technology, applied in the field of food processing, can solve the problems of hard taste, low dietary fiber content, high carbohydrate content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

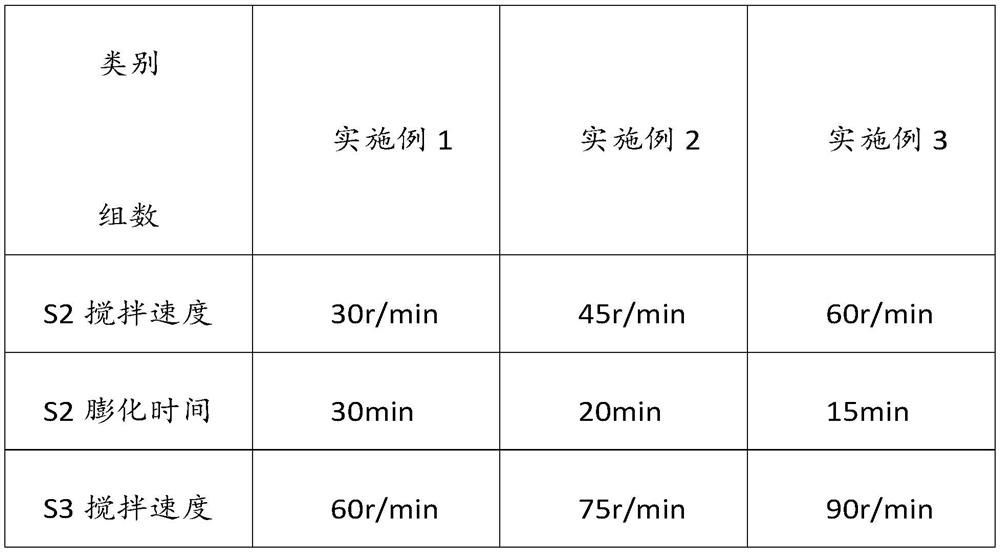

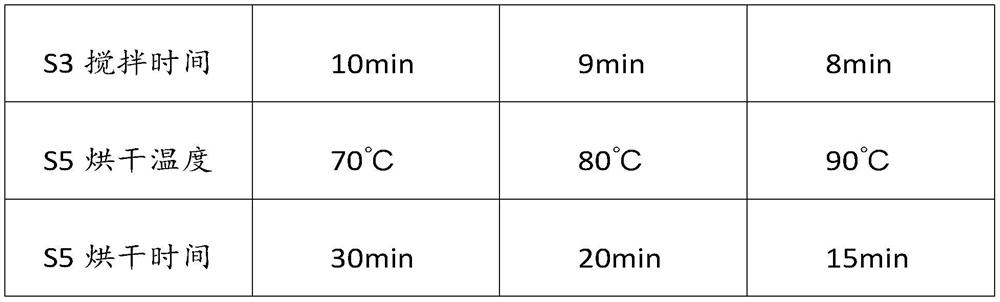

Embodiment 1

[0028] The invention provides a kind of konjac pasta processing technology, comprises the steps:

[0029] S1: Ingredients, use a special capacity device to take a certain amount of konjac dietary fiber powder, soybean powder, starch and water respectively, and set aside. The capacity of the capacity device in the step S1 is 500ml. Before weighing the materials, ensure that the inside of the capacity device is clean to ensure Clean the interior of the capacity appliance to prevent impurities from entering the material and affect the quality of the food. After pouring the material away, observe that there is no obvious residue in the inner wall of the capacity appliance. Raw material proportioning accuracy, konjac dietary fiber powder, soybean flour, starch and water are 1:6:2:3 by volume in the described step S1;

[0030] S2: Pour water into the cleaned blender, then add konjac dietary fiber powder and turn on the blender to stir, so that the konjac dietary fiber powder and wat...

Embodiment 2

[0035] The invention provides a kind of konjac pasta processing technology, comprises the steps:

[0036] S1: Ingredients, use a special capacity device to take a certain amount of konjac dietary fiber powder, soybean powder, starch and water respectively, and set aside. The capacity of the capacity device in the step S1 is 500ml. Before weighing the materials, ensure that the inside of the capacity device is clean to ensure Clean the interior of the capacity appliance to prevent impurities from entering the material and affect the quality of the food. After pouring the material away, observe that there is no obvious residue in the inner wall of the capacity appliance. Raw material proportioning accuracy, konjac dietary fiber powder, soybean flour, starch and water are 1:6:2:3 by volume in the described step S1;

[0037]S2: Pour water into the cleaned blender, then add konjac dietary fiber powder and turn on the blender to stir, so that the konjac dietary fiber powder and wate...

Embodiment 3

[0042] The invention provides a kind of konjac pasta processing technology, comprises the steps:

[0043] S1: Ingredients, use a special capacity device to take a certain amount of konjac dietary fiber powder, soybean powder, starch and water respectively, and set aside. The capacity of the capacity device in the step S1 is 500ml. Before weighing the materials, ensure that the inside of the capacity device is clean to ensure Clean the interior of the capacity appliance to prevent impurities from entering the material and affect the quality of the food. After pouring the material away, observe that there is no obvious residue in the inner wall of the capacity appliance. Raw material proportioning accuracy, konjac dietary fiber powder, soybean flour, starch and water are 1:6:2:3 by volume in the described step S1;

[0044] S2: Pour water into the cleaned blender, then add konjac dietary fiber powder and turn on the blender to stir, so that the konjac dietary fiber powder and wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com