Real-time regulation and control wall surface resonance ultrasonic metal solidification device and method

A technology for metal solidification and real-time control, applied in the configuration of safety devices, metal processing equipment, indicating equipment/measuring equipment, etc. The effect of avoiding solidification speed, increasing speed and prolonging working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

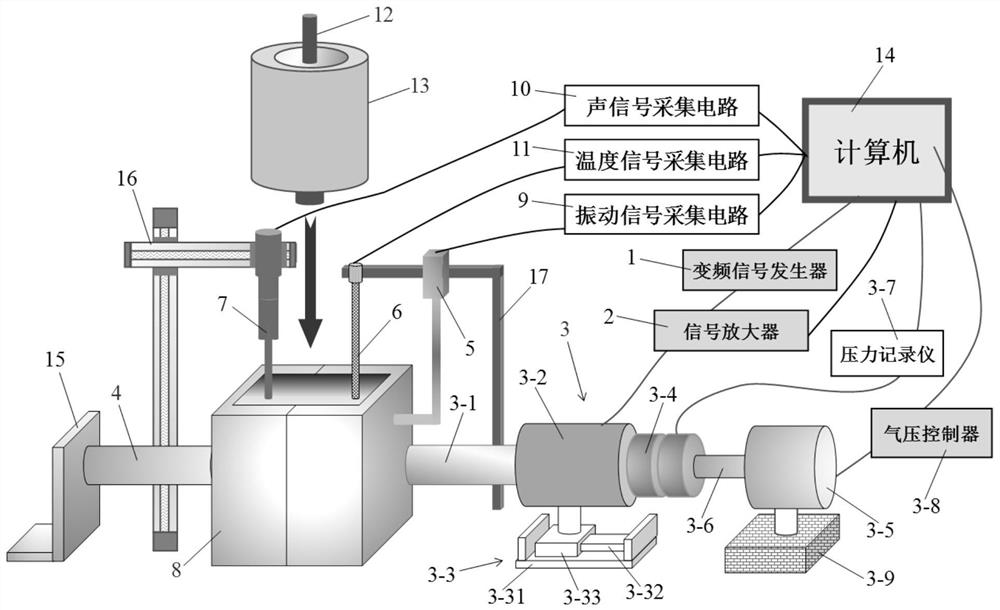

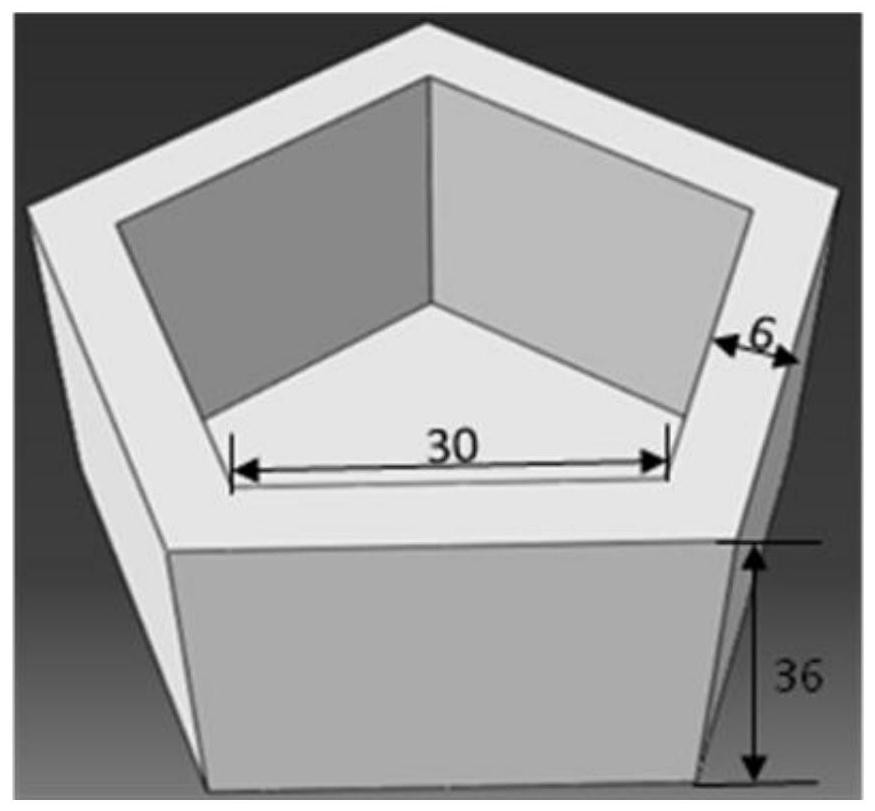

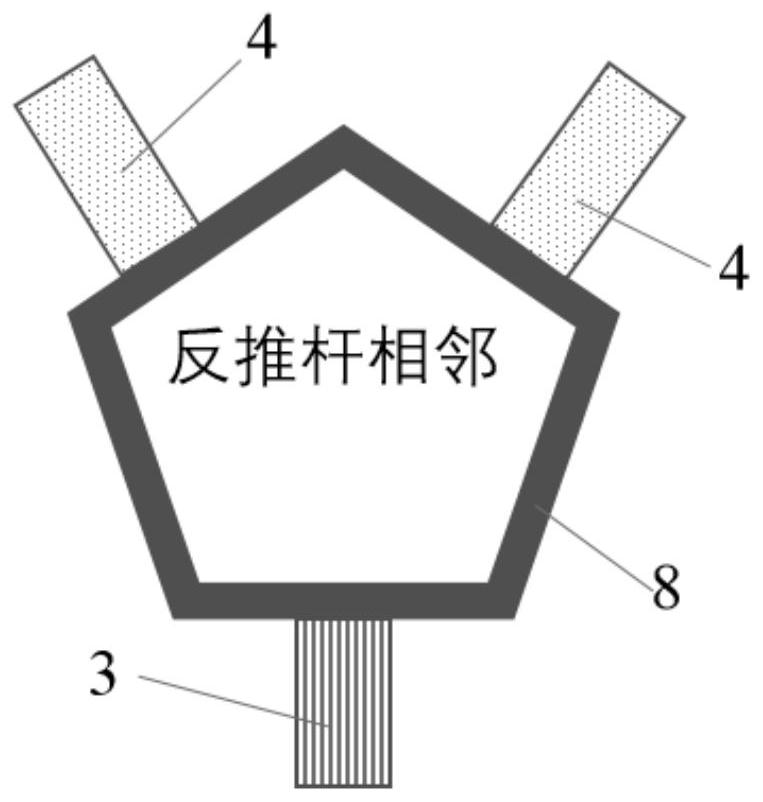

[0080] like figure 1 As shown, the real-time regulated wall surface resonance ultrasonic metal solidification device of the present embodiment includes a metal solidification device body and a metal solidification data acquisition and controller, and the metal solidification device body includes a mold 8 poured from the top and an outer wall of the compression mold 8 The ultrasonic vibration assembly 3 is provided, and the outer wall of the casting mold 8 is also provided with a thrust rod 4 that forms a counter force with the ultrasonic vibration assembly 3 to prevent the casting mold 8 from moving; the top of the casting mold 8 is provided with a solid material for melting alloy And to the smelting crucible 13 of casting in mold 8;

[0081] The metal solidification data acquisition and controller include a sensor group, a signal acquisition circuit group, a computer 14, a frequency conversion signal generator 1 and a signal amplifier 2 connected in sequence, and the sensor g...

Embodiment 2

[0136] like image 3 As shown, the difference between this embodiment and Embodiment 1 is that the ultrasonic vibration assembly 3 includes a sliding guide support 3-3, an ultrasonic transducer 3-2, a horn 3-1 and a The power mechanism that the device 3-2 moves back and forth on the sliding guide support 3-3, and the ultrasonic transducer 3-2 is connected on the sliding guide support 3-3 and can move forward and backward on the sliding guide support 3-3 The ultrasonic transducer 3-2 is connected to the output end of the signal amplifier 2, and the horn 3-1 is connected to the front end of the ultrasonic transducer 3-2 and is used to compress the outer wall of the mold 8, so The rear end of the ultrasonic transducer 3-2 is connected with a pressure sensor 3-4; the power mechanism includes a lead screw connection seat 3-10, a lead screw 3-11 connected to the lead screw connection seat 3-10, a rotating The leading screw nut 3-12 that is connected on the leading screw 3-11 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com