Insect robot with ultra-smooth surface, processing method and application

A technology of robots and insects, applied in the field of insect robots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

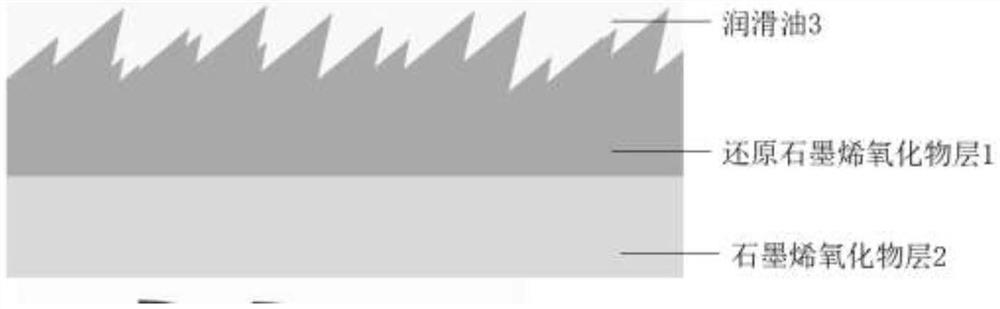

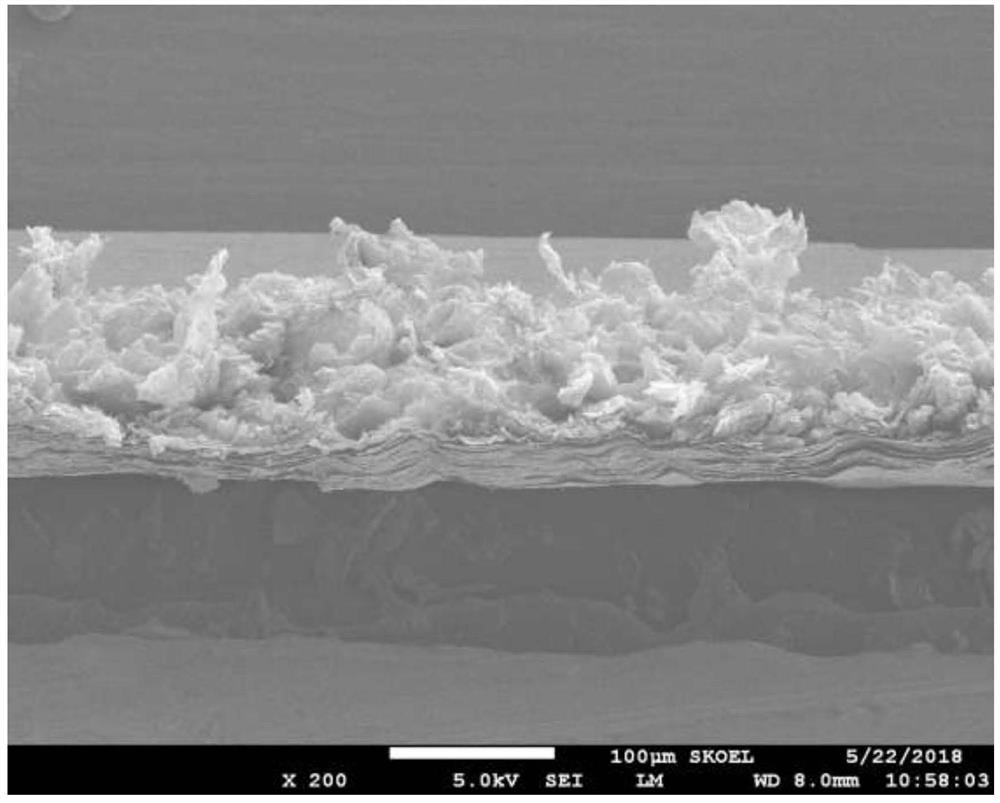

[0035] like figure 1 As shown, the present embodiment provides an insect robot with an ultra-smooth surface, the insect robot has a profiling structure, and is composed of a graphene oxide layer 2 and a reduced graphene oxide layer 1 sequentially from bottom to top. The described reduced graphene oxide layer 1 is a porous structure, obtained by laser processing of the graphene oxide film; the surface of the reduced graphene oxide layer 1 is perfused with lubricating oil 3, and the lubricating oil 3 penetrates into the reduced graphene oxide layer. in the holes of layer 1.

[0036] The lubricating oil 3 is 3M fluorinated lubricating oil, DuPont lubricating oil, silicone oil or edible oil.

[0037]The thickness of the reduced graphene oxide layer 1 is 10-100 μm; the thickness of the graphene oxide layer 2 is 5-10 μm; the thickness of the lubricating oil 3 is 5-10 μm.

[0038] The reduced graphene oxide layer 1 is a porous structure, which is obtained by laser processing the up...

Embodiment 2

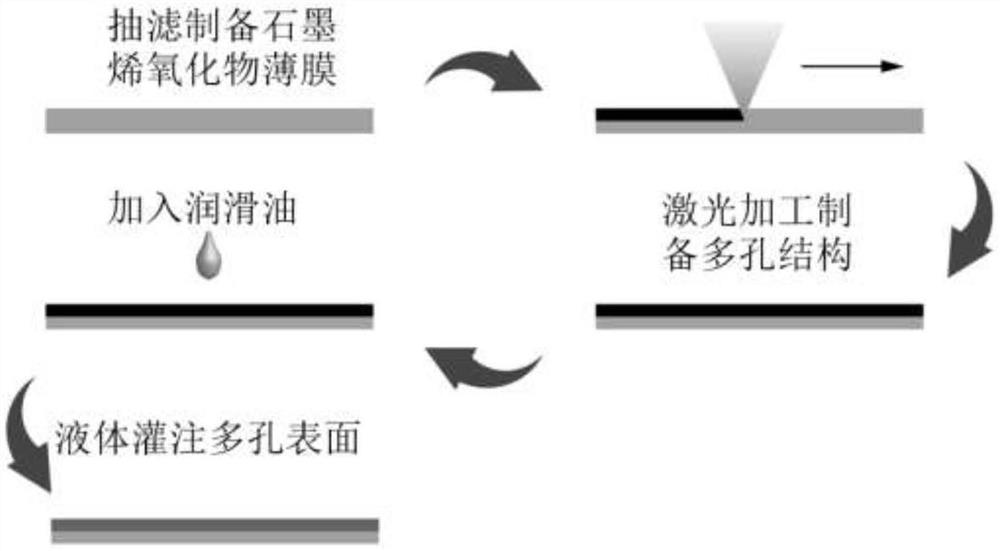

[0040] The present embodiment provides an insect robot with an ultra-smooth surface by using a laser, and the specific steps are as follows:

[0041] (1) Preparation of graphene oxide membrane: After wetting the filter membrane with a pore size of 0.1 μm with a small amount of deionized water, put it flat in the sand core funnel, and then slowly pour it into the sand core at a speed of 0.1 mL / s. Add 10 mL of graphene oxide solution with a concentration of 2 mg / mL into the funnel, and use a vacuum suction filter to perform suction filtration to form a graphene oxide film with a thickness of 15 μm;

[0042] Wherein the graphene oxide solution used is synthesized by Hummer's method, and the specific synthesis steps are:

[0043] First, the NaNO 3 Mix with graphite powder according to the mass ratio of 1:1 under ice bath condition 0°C, add 90mL concentrated sulfuric acid (mass concentration 98%); then, add 7g potassium permanganate, keep ice bath condition (0°C) and use 800 Stir...

Embodiment 3

[0051] Liquid anisotropic transport using laser-fabricated insect robots with ultraslippery surfaces.

[0052] The invention also provides the application of the insect robot with the ultra-slippery surface prepared by the laser for liquid anisotropic transmission, that is, the insect robot has the good liquid transmission ability of the ultra-slippery surface and the bendable performance when it is stimulated by the outside world, The anisotropic transport of liquid can be controlled by controlling the presence or absence of external stimuli.

[0053] Using laser-fabricated insect robots with ultra-slippery surfaces for liquid anisotropic transport, the specific steps are as follows:

[0054] (1), the preparation of graphene oxide film: same as Example 1.

[0055] (2) Preparation of porous structure: the same as in Example 1.

[0056] (3), the preparation of insect robot: the lubricating oil 3 is injected into the reduced graphene oxide layer 1 with porous structure of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com