Full-automatic loading and unloading system compatible with multi-specification materials

An automatic loading and unloading and loading and unloading system technology, applied in the field of tobacco logistics, can solve the problems of different packaging specifications of goods and incompatibility of loading and unloading systems, and achieve the effects of eliminating potential safety hazards, accelerating the process of automation and intelligence, and improving turnover efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

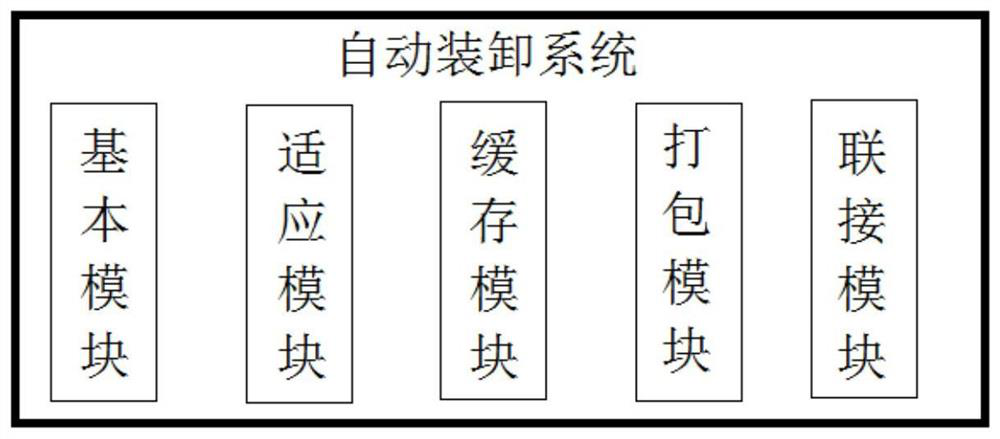

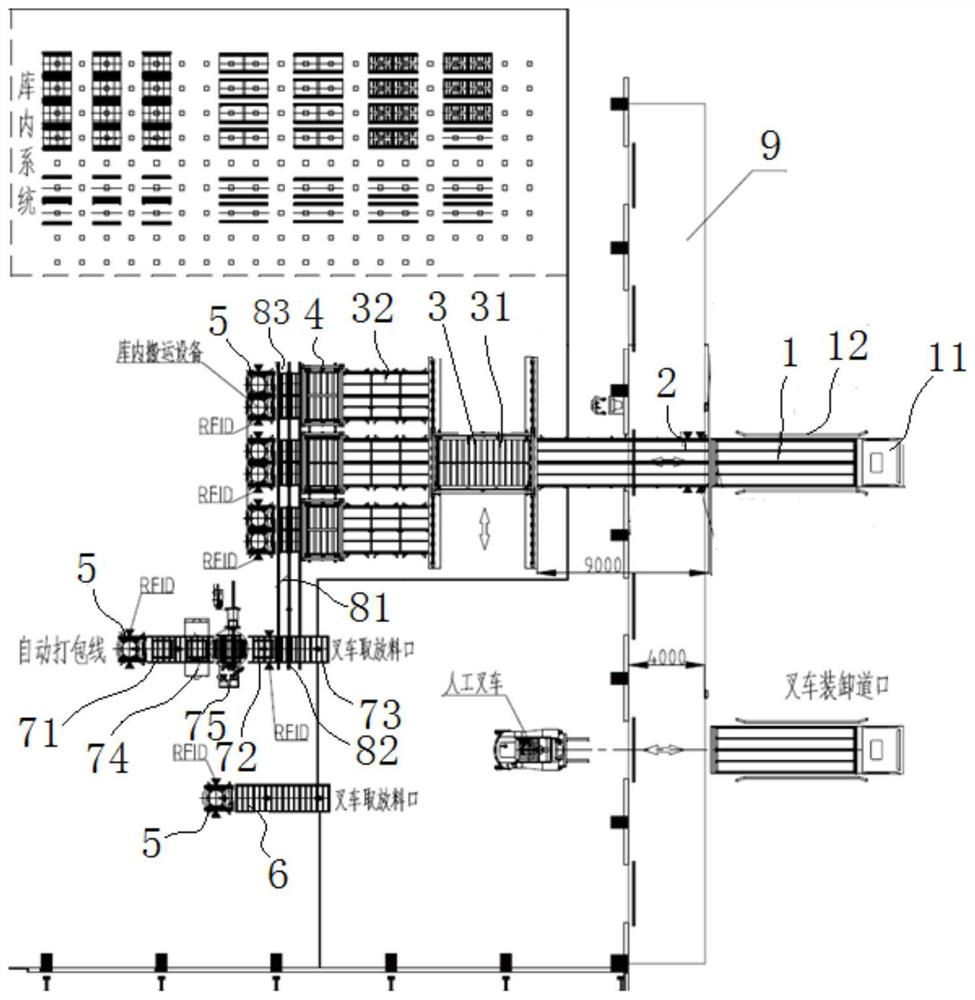

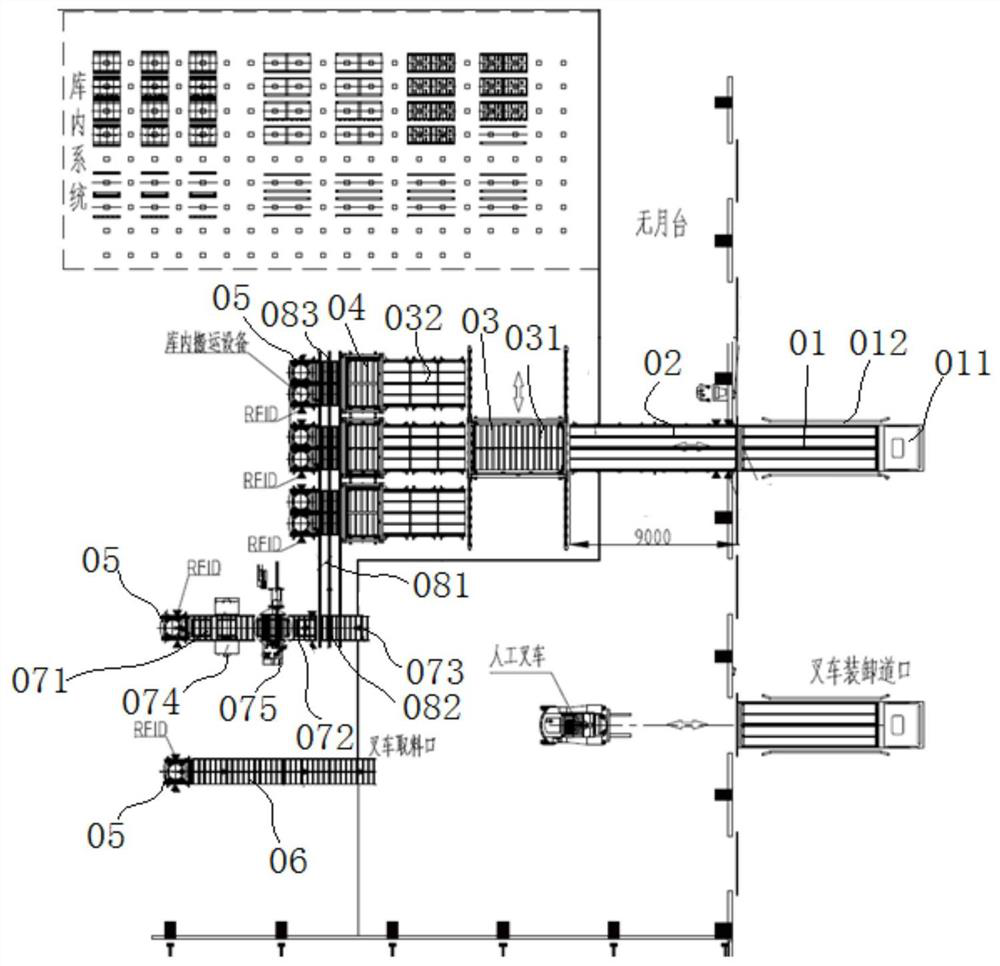

[0046] The invention provides a fully automatic loading and unloading system compatible with multi-standard materials, such as figure 1 As shown, the system mainly includes a basic module, a cache module and an adaptation module. Further optionally, the system may also include a packing module and a connecting module. The system can be highly integrated with WCS warehouse control system and WMS warehouse management system.

[0047] One end of the basic module is used to realize the docking of vehicles or the automatic loading and unloading of goods, and the other end is connected to the buffer module; The other end of the module is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com