Continuous circulating water treatment biochemical pool and water treatment method

A technology of circulating water and biochemical pool, applied in the direction of sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of idle reaction pool and low utilization rate, and reduce structure and cumbersome processes, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

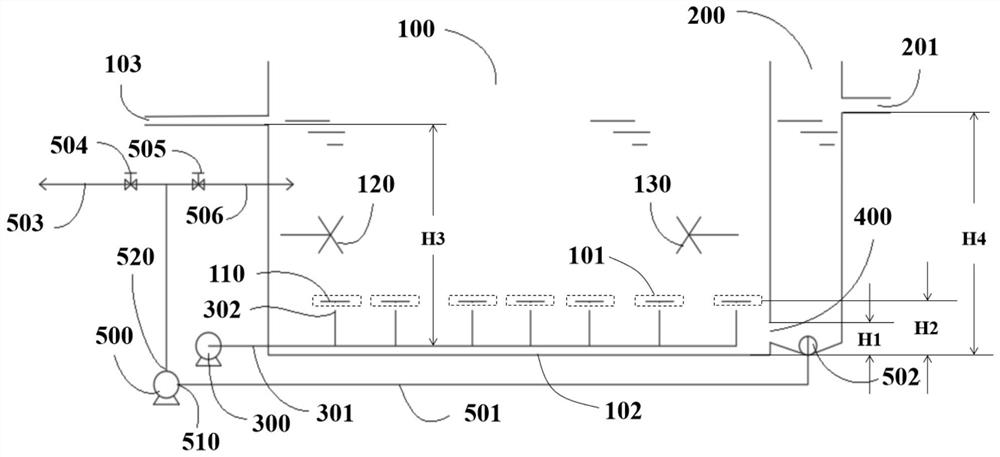

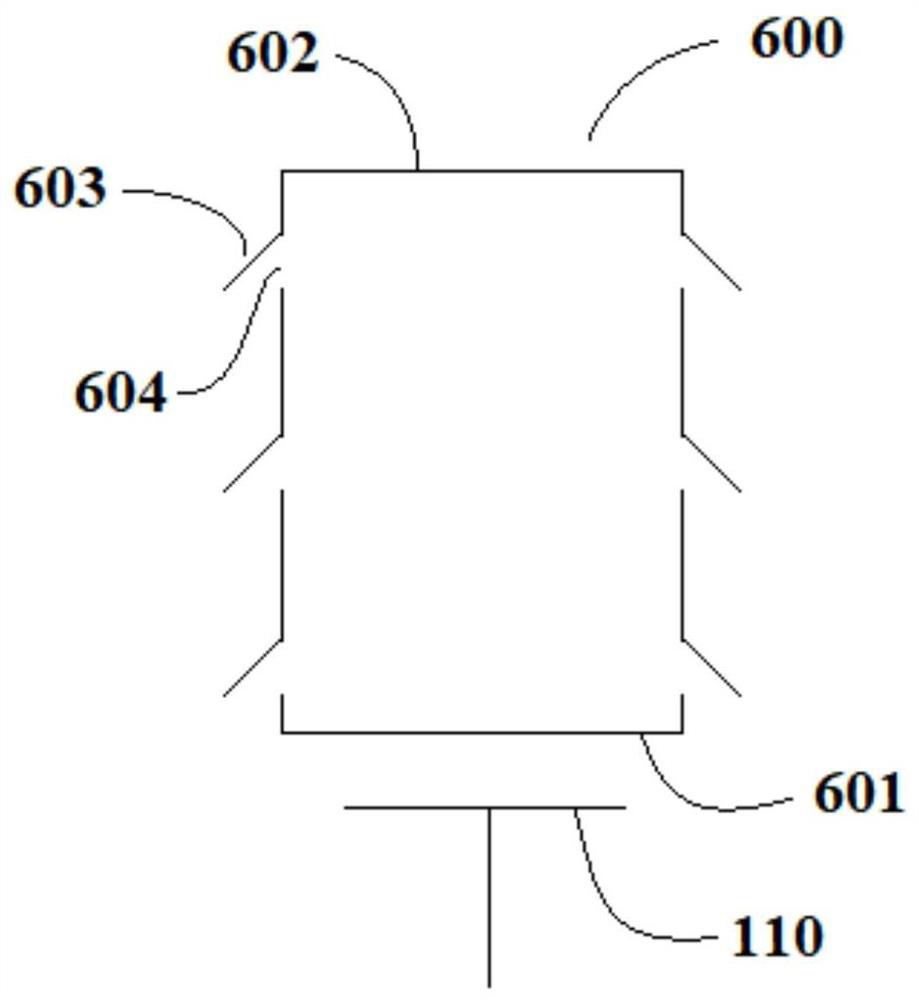

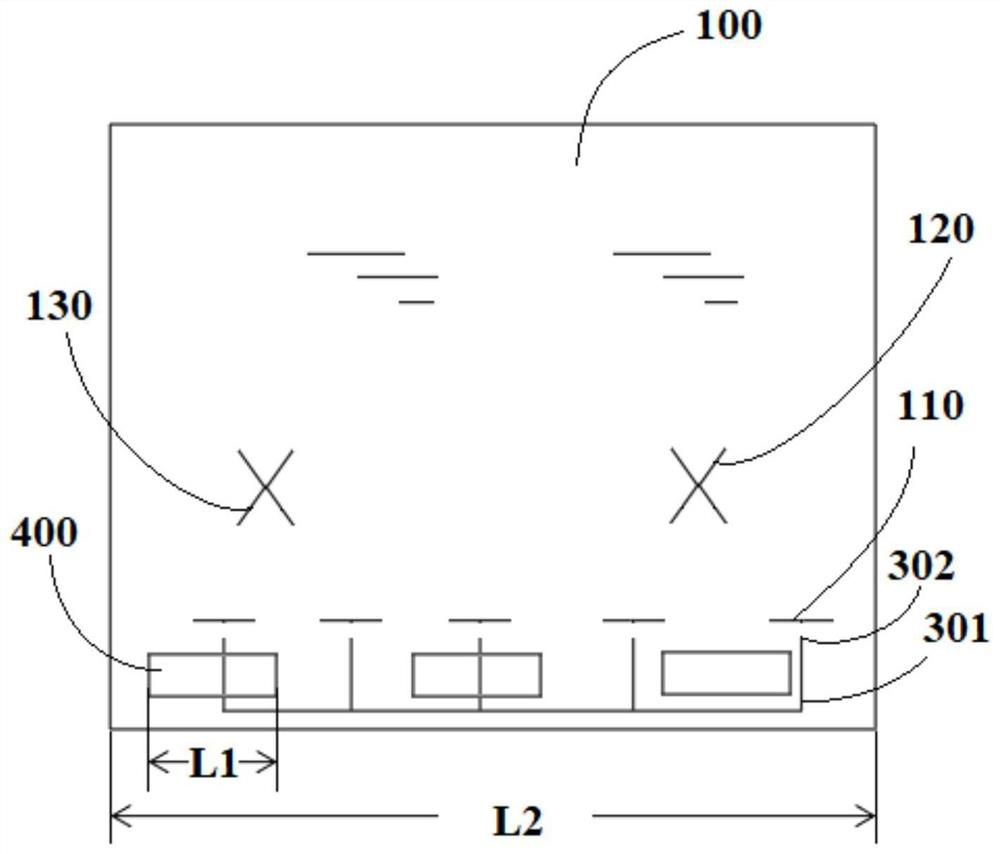

[0041] Such as figure 1 As shown, the present embodiment provides a continuous circulation water treatment biochemical pond, which includes a biochemical reaction zone 100 and a drainage zone 200, and the volume of the biochemical reaction zone 100 is V 1 =1000m 3 , the volume of the drainage area 200 is V 2 =100m 3 , the V 2 :V 1 =0.1:1; the biochemical reaction zone 100 and the drainage zone 200 are connected through the communication hole 400, and the communication hole 400 is provided with n=10, and the opening width of each communication hole is L 1 =1m; the width of the biochemical reaction zone is L 2 =20m; the biochemical reaction zone 100 is provided with an aeration position 101, and the aeration position 101 is provided with an aeration component 110 for aerating the water in the biochemical reaction zone 100, and the aeration component 110 in the present embodiment It is an aeration tray; the height of the connecting hole 400 from the bottom surface 102 of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com