Preparation method of foaming heat-insulation phosphate adhesive

A phosphate adhesive, foaming heat insulation technology, applied in the direction of adhesives, adhesive additives, inorganic adhesives, etc., can solve the problems of high thermal conductivity and poor heat insulation performance, and achieve low density and good heat insulation Effect, excellent high temperature stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

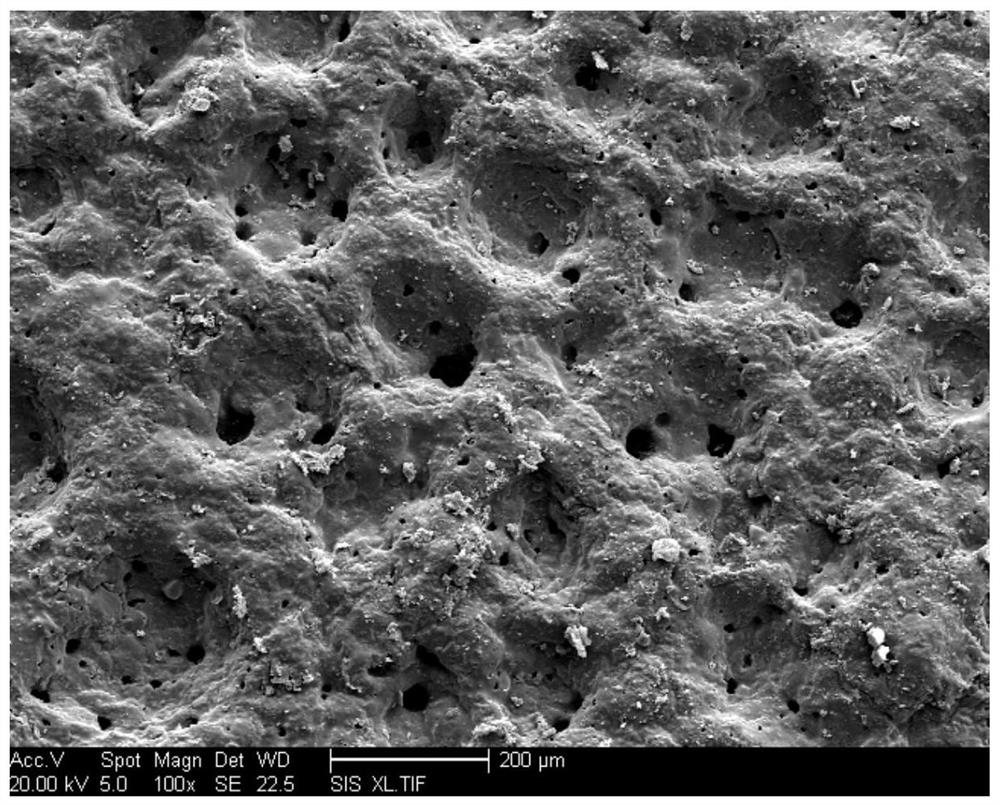

Image

Examples

specific Embodiment approach 1

[0020] Specific implementation mode 1: In this implementation mode, a method for preparing a foamed heat-insulating phosphate adhesive is specifically carried out according to the following steps:

[0021] 1. Heat the industrial-grade aluminum dihydrogen phosphate solution to obtain a saturated salt solution. Control the heating temperature at 78-82°C, then lower the temperature to -18-20°C and keep it for 12-13 hours. Aluminum dihydrogen phosphate crystallizes at the bottom and freezes on the upper layer , the ice is separated to obtain crystallized aluminum dihydrogen phosphate;

[0022] 2. Add acetone and auxiliary agents to the aluminum dihydrogen phosphate obtained in step 1, fully dissolve, and obtain the phosphate adhesive matrix;

[0023] 3. Mix forsterite sand with a particle size of 120-200 μm, magnesia-zircon sand with a particle size of 100-150 μm, alumina with a particle size of 10-50 μm and alumina with a particle size of 150-200 μm, disperse at high speed, and t...

specific Embodiment approach 2

[0026] Embodiment 2: This embodiment differs from Embodiment 1 in that the auxiliary agent described in step 2 is a silane coupling agent. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0027] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is that in step 2, according to the mass parts, the aluminum dihydrogen phosphate is 70-100 parts, the acetone is 29-120 parts, and the auxiliary agent is 1 part . Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com