Shield shaft ell end large pipe shed structure based on double-layer lining and construction method

A technology for shield wells and large pipe sheds, which is applied in shaft lining, tunnel lining, shaft equipment, etc., and can solve the problems of failure to meet environmental protection requirements around shield wells, structural waterproof requirements, and penetration of shield well end walls, etc. problems, to avoid unstable factors, high economic and social benefits, and low construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

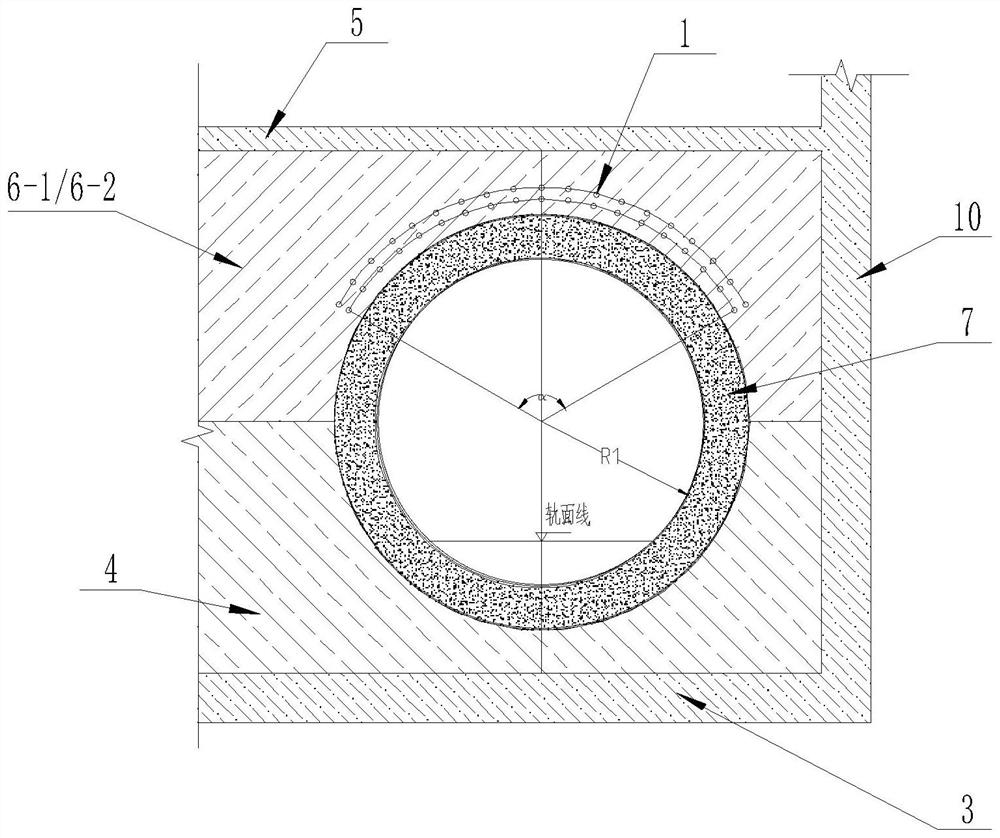

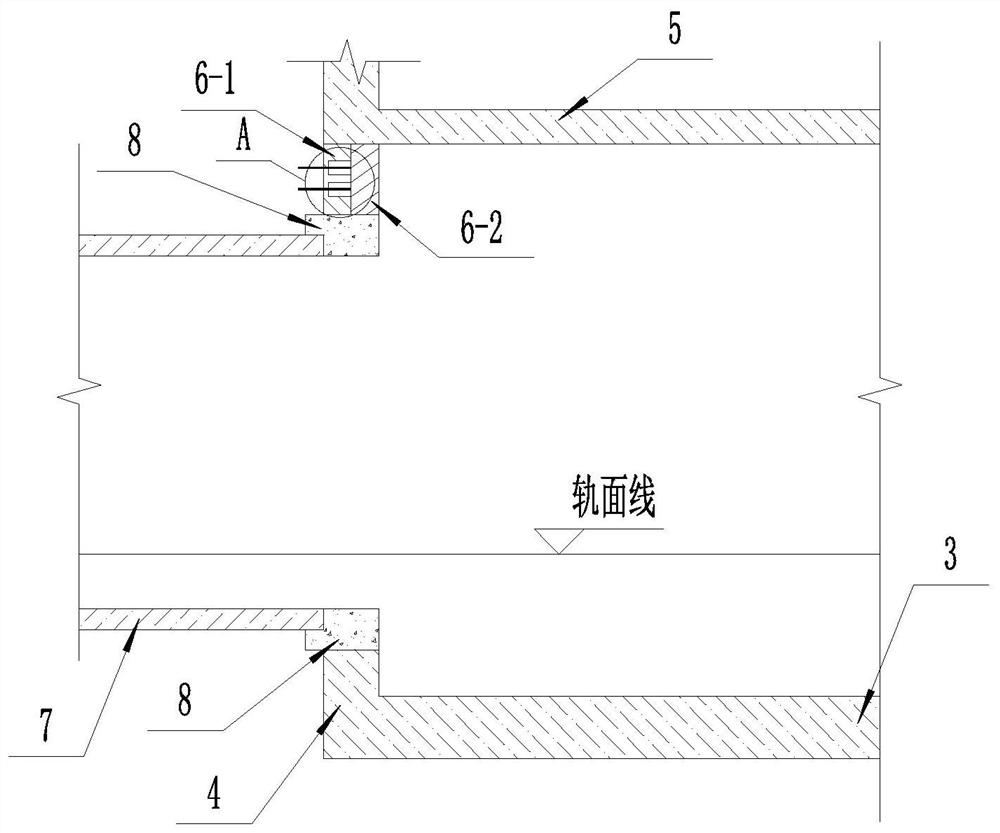

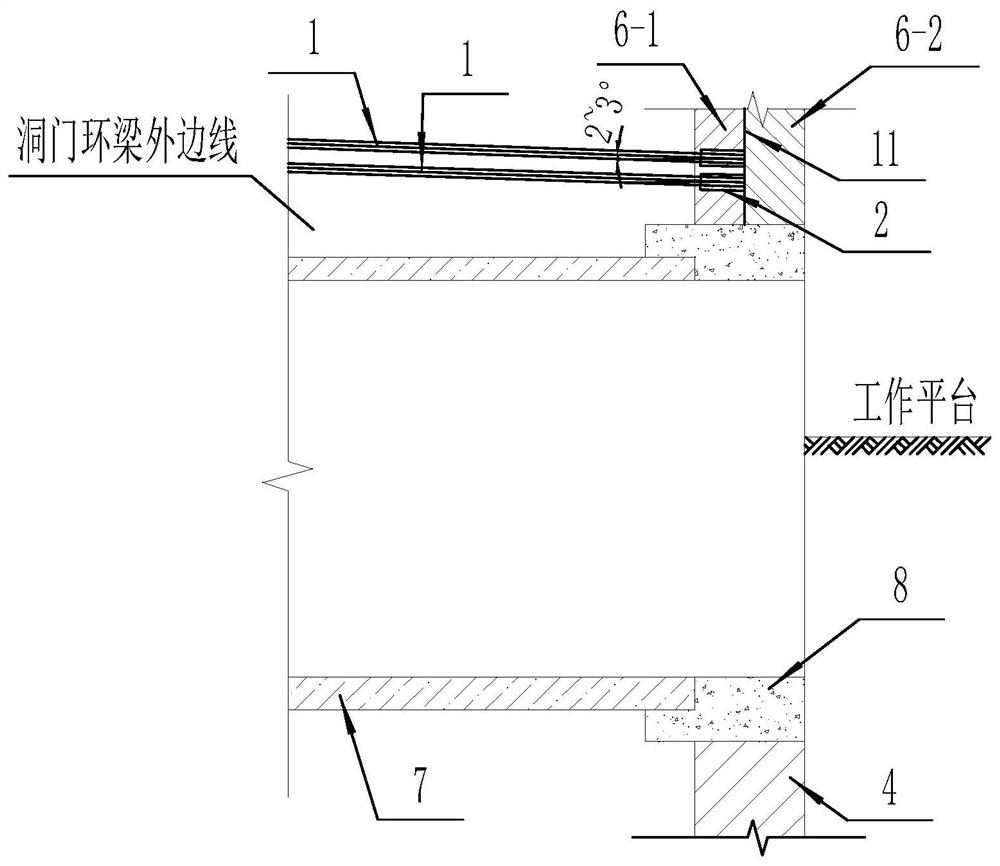

[0036] refer to Figure 1-Figure 4 A large pipe shed structure at the end of a shield well based on double-layer lining is shown, including a large pipe shed 1, a pipe shed guide pipe 2, a shield well bottom plate 3, a shield downhole end wall 4, a shield well mid-plate 5, The upper end wall of the shield tunnel, the shield tunnel 7, the post-cast ring beam 8 of the shield tunnel door, and the side wall 10 of the shield tunnel; the bottom of the shield tunnel 7 is provided with a shield tunnel bottom plate 3, The upper part of the end of the tunnel 7 is provided with a shield well plate 5, and a shield well side wall 10 is provided on one side of the shield well center plate 5 and the shield well bottom plate 3; a shield well end is provided at the end of the shield tunnel 7 The shield shaft end wall is composed of the shield tunnel end wall 4 and the shield tunnel upper end wall, the shield shaft upper end wall is located at the upper part of the shield tunnel end wall 4, and...

Embodiment 2

[0042] refer to figure 1 and Figure 4 The shown one based on the double-layer lining of the large pipe shed structure at the end of the shield well is different from the first embodiment in that: the two sides of the pipe shed guide pipe 2 are provided with pipe shed guide pipe positioning steel bars 9, and the pipe shed The guide pipe positioning steel bar 9 is connected with the main reinforcement in the shield tunnel end wall 4 and the shield tunnel upper end outer wall 6-1.

[0043] The adoption of the technical solution in actual use makes the structure of the present invention have a higher degree of integration, better stability, and ensures controllable precision of laying large pipe sheds.

Embodiment 3

[0045] refer to figure 1 and image 3 The shown one based on the double-layer lining of the large pipe shed structure at the end of the shield well is different from the first embodiment in that: the pipe shed guide pipe 2 is arranged in an arc shape, and the number of rows is not less than two .

[0046] Preferably, the pipe shed guide pipe 2 is arranged within the range of 120°-150° of the arch portion directly above the shield tunnel 7, with a circumferential distance of 0.3m-0.4m.

[0047] In actual use, the pipe shed guide pipe 2 adopts this technical solution, which not only meets the stability requirements of the present invention, but also can ensure that the laying accuracy of the large pipe shed is controllable,

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com