Arc tenon blade root extension structure design method

A technology of structural design and circular arc, which is applied to mechanical equipment, parts of pumping devices for elastic fluids, non-variable pumps, etc., can solve problems such as unsatisfactory distribution, optimal processing, and inability to shorten the design Effects vs. modeling time, good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them.

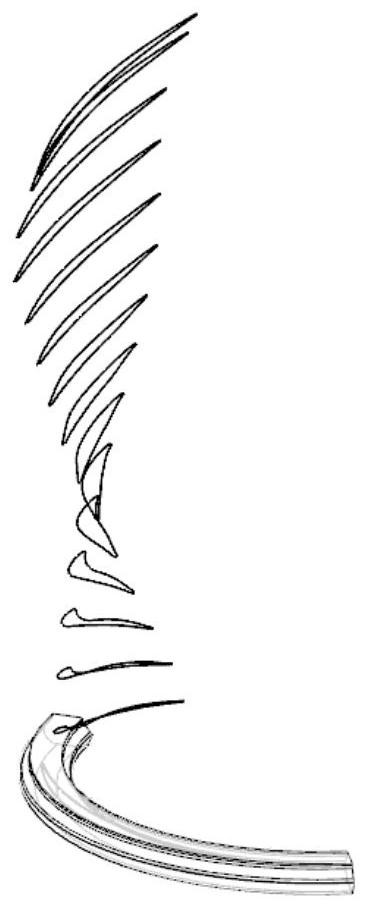

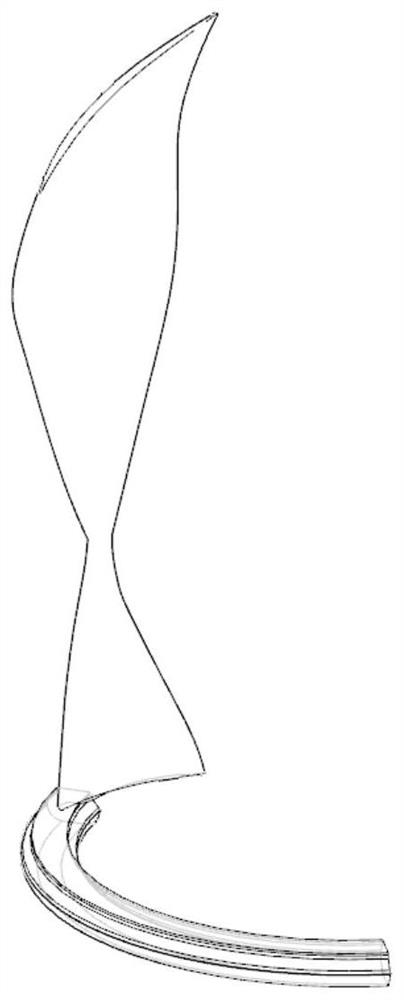

[0037] In order to solve the problems existing in the existing technology, such as Figure 1 to Figure 4 As shown, the present invention provides a method for designing the root extension structure of a circular tenon blade, comprising the following steps:

[0038] S1. Determine the design parameters:

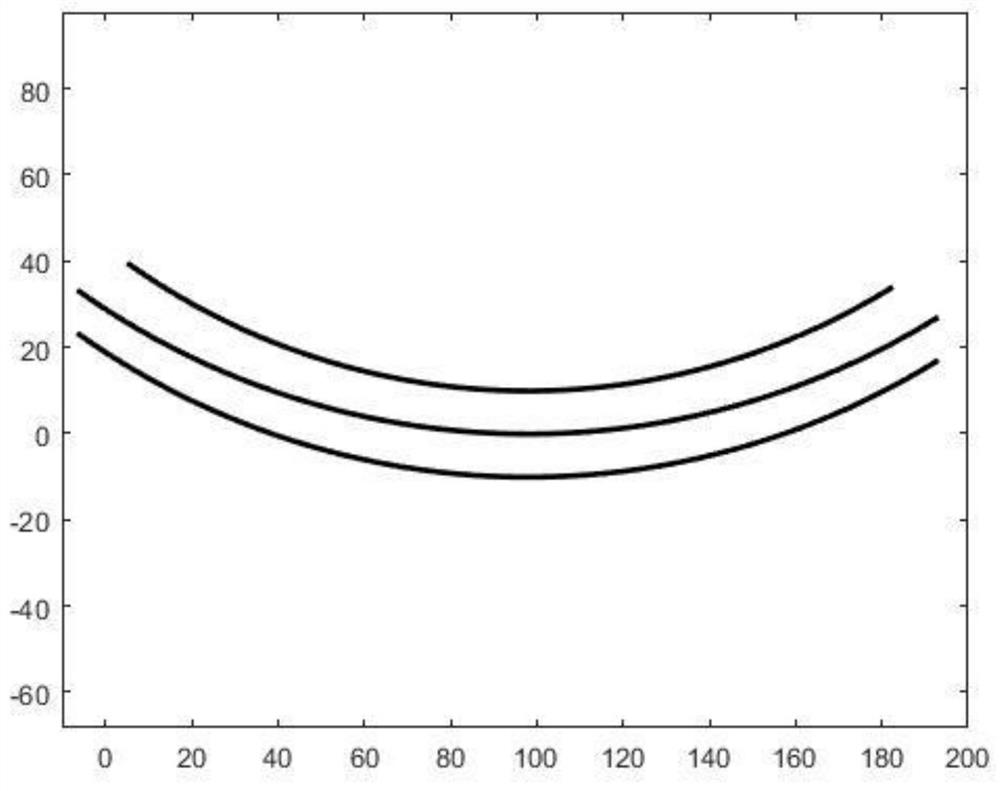

[0039] like figure 1 As shown, the aerodynamic profile of the hollow blade and the characteristic parameters of the arc tenon are given. like figure 2 As shown, the solid model of the hollow blade body and the arc tenon is determined according to the shape data of the blade and the tenon; the radius of the inner and outer boundaries of the arc tenon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com