Medium strain rate test equipment and method with axial pressure and confining pressure controlled loading

A test equipment and strain rate technology, applied in the direction of applying stable tension/pressure to test the strength of materials, instruments, measuring devices, etc., can solve the problem of uncontrollable axial loading and confining pressure of samples, discrete test results, and lack of mechanical properties Understand and other problems to achieve the effect of accurate and stable mechanical properties of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

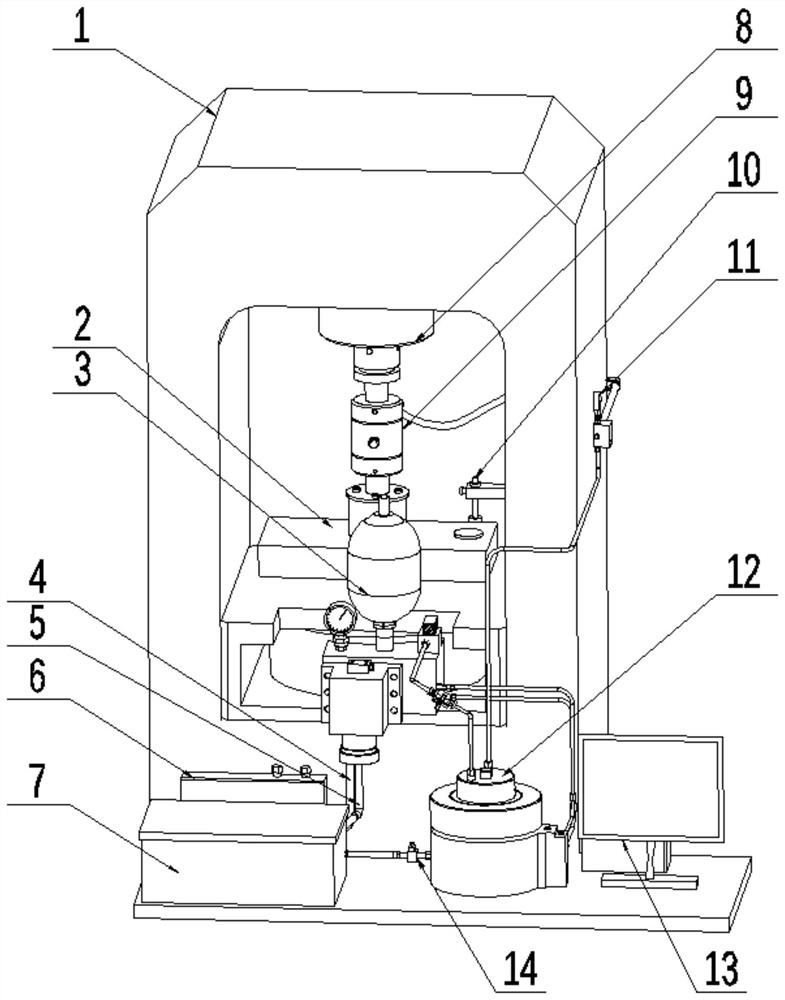

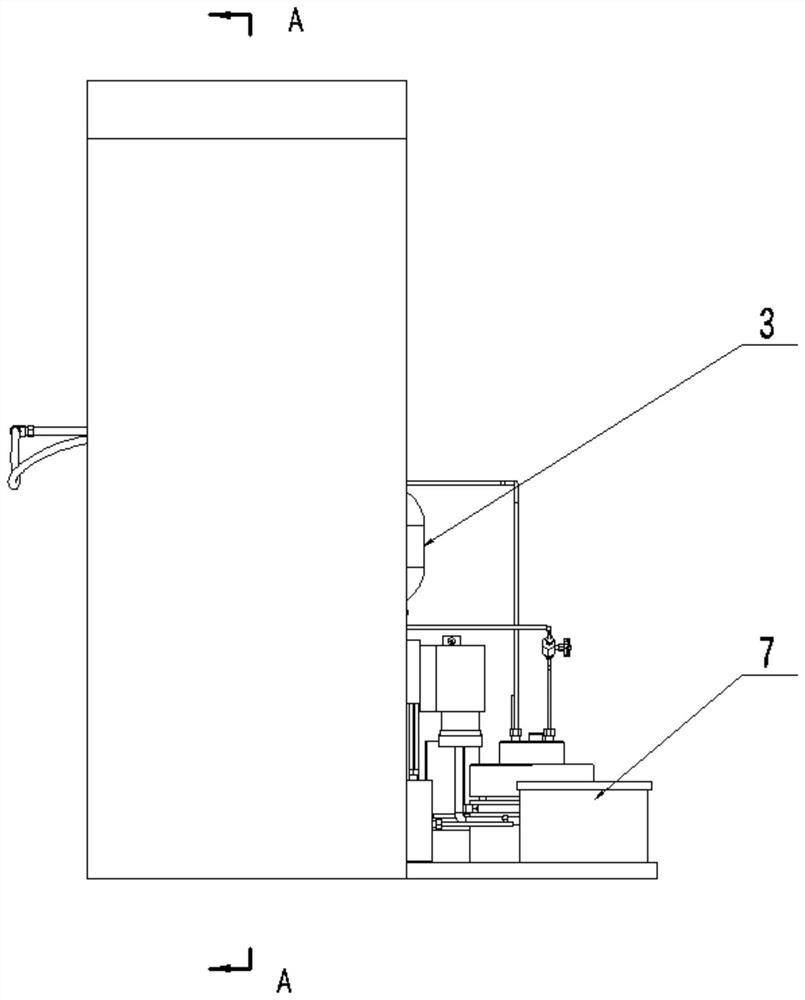

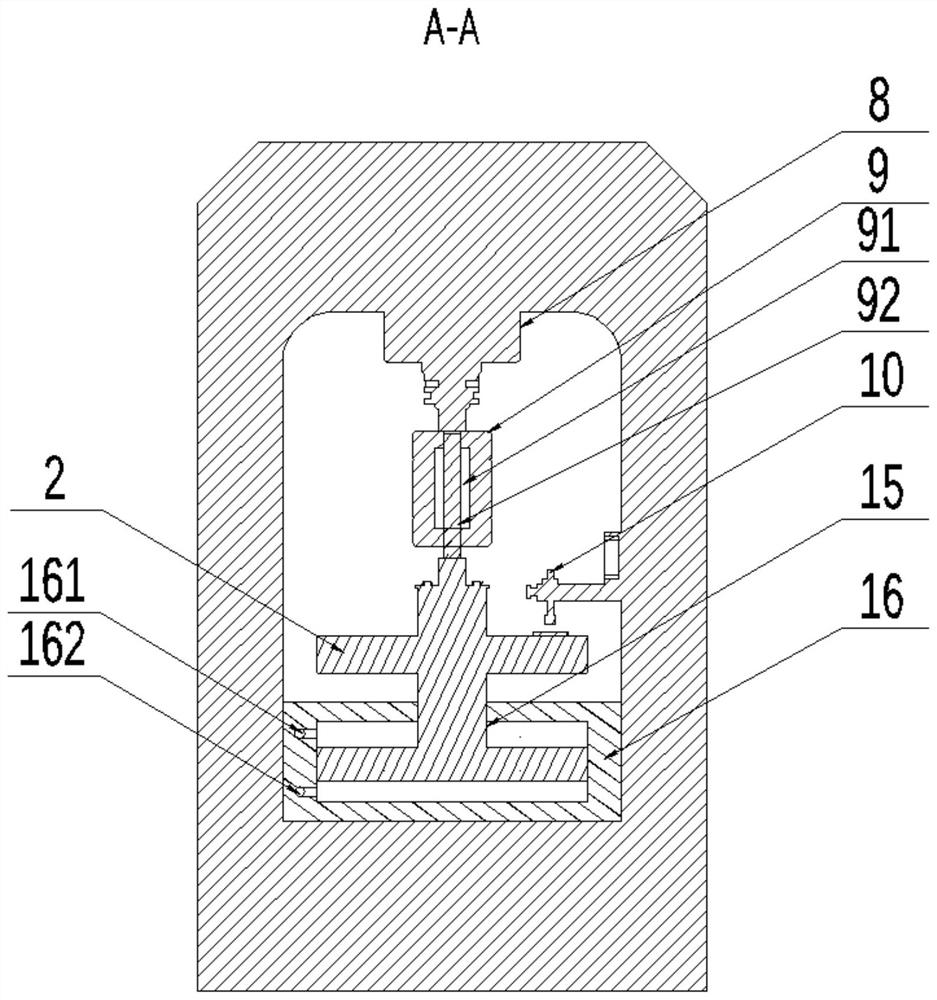

[0049] 1. The medium strain rate test equipment provided by the present invention with axial pressure and confining pressure control loading is used to test the rock sample 92. The rock sample 92 adopts a cylindrical rock sample with a diameter of 30 mm and a height of 60 mm. The sample 92 is placed in the triaxial confining pressure chamber 4, and different confining pressure (10, 20, 30, 40, 50 MPa) conditions are loaded through the servo control of the confining pressure loading system, and different loads are loaded through the servo control of the axial loading system, Dynamic triaxial tests were performed on rock samples. like figure 2 As shown, a cross-shaped strain rosette 921 is arranged at the midpoint in the height direction of the rock sample to measure the axial strain and lateral strain of the sample during the loading process, and the strain data is collected in real time by the high-speed strain gauge 17 during the loading process.

[0050] By loading under d...

Embodiment 2

[0056] Test the variation curves of axial stress and axial strain, lateral strain and volumetric strain of a certain rock sample under the condition of confining pressure 10MPa (see Figure 8 ), axial strain ε a and lateral strain ε l Acquired by the high-speed strain gauge 17, the volumetric strain is calculated according to the formula ε v =ε a +2×ε l , where ε v is the volumetric strain, ε a is the axial strain, ε l is the lateral strain, such as Figure 7 As shown, the variation curves of deviatoric stress and axial strain, lateral strain and volumetric strain of a certain sample are similar to the static test results, which verifies the effectiveness of this equipment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com