Machining device and machining method for conical groove in surface of grooved pin

A processing device and technology with grooved pins, applied in the field of machining, can solve the problems of difficult assembly of finished products, chipping, etc., and achieve the effects of reducing weight, solving processing difficulties, and installing and replacing extrusion tools conveniently and quickly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

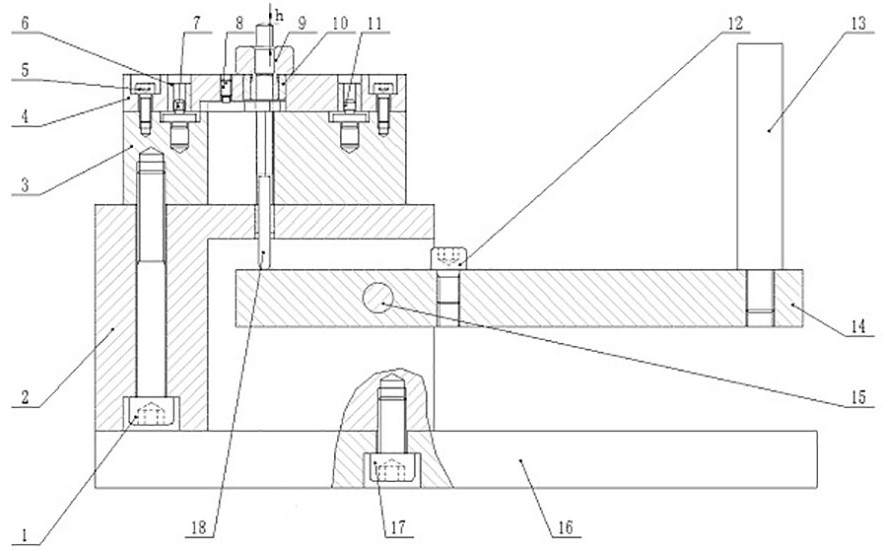

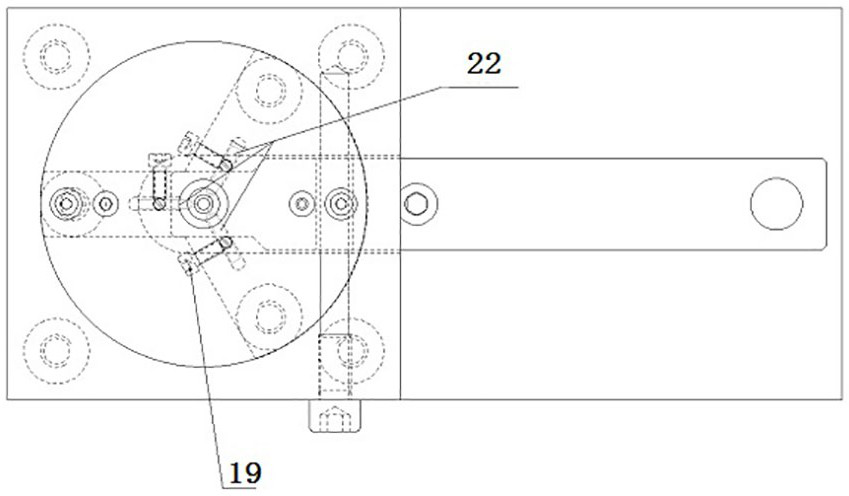

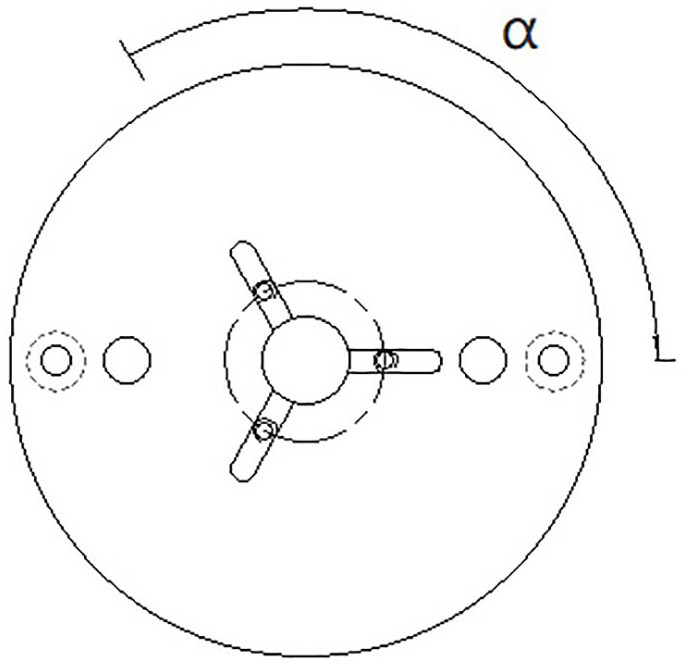

[0052] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0053] Such as figure 1 , 2 As shown, a processing device for tapered grooves on the surface of a grooved pin includes a hydraulic press for applying pressure, an extrusion fixture for clamping a workpiece, and an extrusion tool 22 installed in the extrusion fixture; the extrusion fixture includes a set The bottom plate 16 in contact with the workbench at the bottom of the processing device, the base 2 installed on the upper side of the base plate 16, the extruding knife seat 3 installed on the upper end of the base 2, and the guide block 4 installed on the upper end of the extruding knife seat 3 , the pressure handle 14 connected to the inside of the base 2 through the shaft 15 and the movable guide sleeve 9 arranged on the upper end of the guide block 4; the middle position of the extruding tool holder 3 is provided with a cylindrical through hole 2 for placing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com