A preparation method of silver-nickel-graphite electric contact with continuous decarburization layer on the side

A technology of decarburization layer and electric contact, applied in the direction of contacts, circuits, electric switches, etc., can solve the problems of high service life, high material cost, general anti-welding ability, etc., to improve mechanical life, increase hardness, The effect of good welding resistance

Active Publication Date: 2022-06-10

ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

View PDF9 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] At present, the static points of miniature circuit breakers are basically extruded silver graphite materials. The advantage is that the service life is long, and the disadvantage is that the material cost is high and the anti-welding ability is average.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

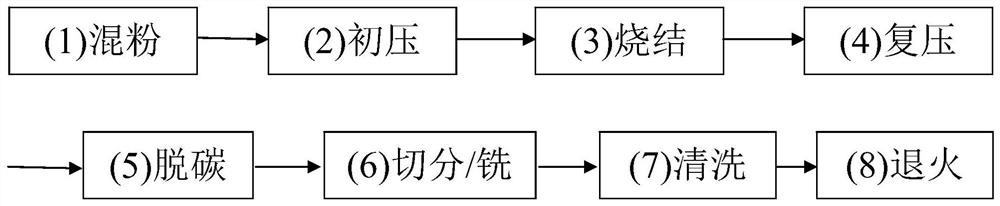

The invention discloses a method for preparing a silver-nickel-graphite electric contact with a continuous decarburization layer on the side, which comprises the following steps: (1) powder mixing, uniformly mixing silver powder, nickel powder and graphite powder; (2) initial press molding ; (3) sintering, sintering the compact under a reducing atmosphere; (4) repressing, repressing the sintered compact to obtain a recompact; (5) decarburization, placing the recompact Heating in compressed air for decarburization, thereby forming a continuous decarburization layer on its surface; (6) cutting or milling, dividing the decarburized silver-nickel graphite billet into two to obtain two contacts; or milling off one side silver layer to obtain a monolithic contact; (7) cleaning, the contact obtained in step (6) is subjected to grinding, polishing and drying; (8) annealing, the cleaned product is annealed in a reducing atmosphere, and passed Annealing restores the oxidized nickel back to the finished product. In the silver-nickel-graphite electric contact prepared by the invention, the graphite is distributed in an arbitrary structure, the contact has strong anti-welding ability; the side has a continuous decarburization layer, and the contact has a long mechanical life.

Description

A kind of preparation method of silver-nickel-graphite electrical contact with continuous decarburization layer on side technical field The present invention relates to the field of electrical contact material science, specifically refers to a kind of silver-nickel graphite with continuous decarburization layer on the side The preparation method of the electrical contact and the product thereof. Background technique [0002] The silver-nickel-graphite electrical contacts produced by powder metallurgy technology are mainly used in frame circuit breakers as static points. Depend on It is used to replace part of silver with nickel, and the material cost is relatively low. The processing technology of silver-nickel-graphite electrical contacts is mainly a molding process, which is the mixed powder of graphite powder, nickel powder and silver powder. It is filled into the cavity for single-piece pressing, and the compact is divided into two layers: the silver-nickel graphi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B22F3/16B22F3/24H01H1/023H01H1/027H01H11/04C22C5/06C22C1/05

CPCB22F3/16B22F3/24H01H1/023H01H1/027H01H11/048C22C5/06C22C1/05B22F2003/248B22F2003/247B22F2999/00B22F2201/32B22F2201/01

Inventor 费家祥宋振阳林旭彤刘映飞宋林云李小珍孔欣林万焕

Owner ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com