Preparation method of silver-nickel-graphite electrical contact with continuous decarburization layer on side surface

A technology of decarburization layer and electrical contacts, applied in the direction of contacts, circuits, electrical switches, etc., can solve the problems of high service life, high material cost, general anti-welding ability, etc., to improve mechanical life, improve hardness, The effect of good resistance to fusion welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

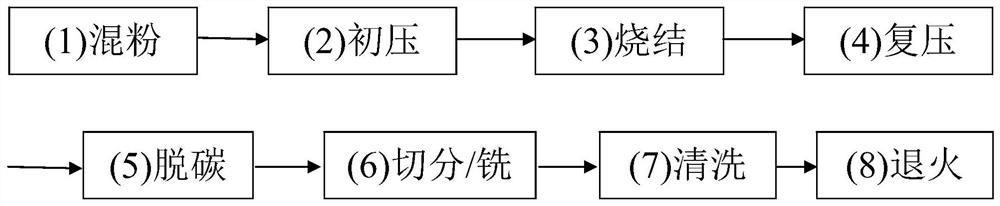

[0027] 1) 18.6kg silver powder, 0.4kg nickel powder and 1kg graphite powder are mixed uniformly to obtain AgNi2C5 mixed powder;

[0028] 2) AgNi2C5 mixed powder is pressed into shape by molding method;

[0029] 3) Put the compact into a sintering furnace for sintering, heat it at 940°C for 2 hours, and protect it with hydrogen;

[0030] 4) Use 11t / cm 2 The pressure is repressurized;

[0031] 5) Decarburizing the compact in a decarburization furnace at 600°C;

[0032] 6) Cut the product into two parts from the middle of the thickness to obtain two pieces of contacts;

[0033] 7) Cleaning, grinding, polishing and drying the contacts;

[0034] 8) Annealing, the product is annealed in a sintering furnace under the protection of hydrogen at 600°C for 2 hours to obtain the final product, or further re-solder on this basis to obtain the final product.

[0035] This embodiment finally obtains the AgNi2C5 electrical contact of any structure with a continuous decarburization layer ...

Embodiment 2

[0037] 1) 47kg silver powder, 1kg nickel powder and 2kg graphite powder are mixed uniformly to obtain AgNi2C4 mixed powder;

[0038] 2) AgNi2C4 mixed powder is pressed into shape by molding method;

[0039] 3) Put the compact into a sintering furnace for sintering, heat it at 900°C for 3 hours, and protect it with hydrogen;

[0040] 4) Use 10t / cm 2 The pressure is repressurized;

[0041] 5) Decarburizing the compact in a decarburization furnace at 700°C;

[0042] 6) Mill one side of the silver layer of the product with special equipment, and keep the other side of the silver layer for welding to obtain a single-chip contact;

[0043] 7) Cleaning, grinding, polishing and drying the contacts;

[0044] 8) Annealing, the product is annealed in a sintering furnace under the protection of hydrogen at 500°C for 3 hours to obtain the final product, or further re-soldering on this basis to obtain the final product.

Embodiment 3

[0046] 1) 9.4kg silver powder, 0.3kg nickel powder and 0.3kg graphite powder are mixed uniformly to obtain AgNi3C3 mixed powder;

[0047] 2) AgNi3C3 mixed powder is pressed into shape by molding method;

[0048] 3) Put the green compact in a sintering furnace for sintering, heat it at 860°C for 4 hours, and protect it with hydrogen;

[0049] 4) Use 9t / cm for the green compact 2 The pressure is repressurized;

[0050] 5) Decarburizing the compact in a decarburization furnace at 800°C;

[0051] 6) Cut the product into two parts from the middle of the thickness to obtain two pieces of contacts;

[0052] 7) Cleaning, grinding, polishing and drying the contacts;

[0053] 8) Annealing, the product is annealed in a sintering furnace under the protection of hydrogen at 400°C for 4 hours to obtain the final product, or further re-solder on this basis to obtain the final product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com