Bar feeding device for cutting machine

A supply device and cutting machine technology, applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve the problems of increasing labor intensity and low safety of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

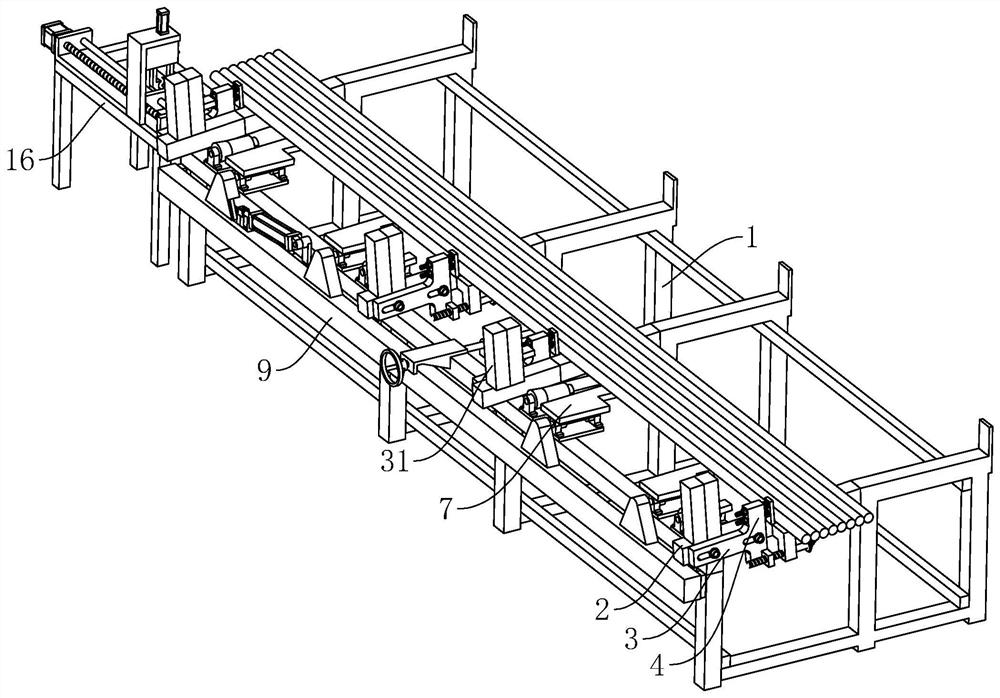

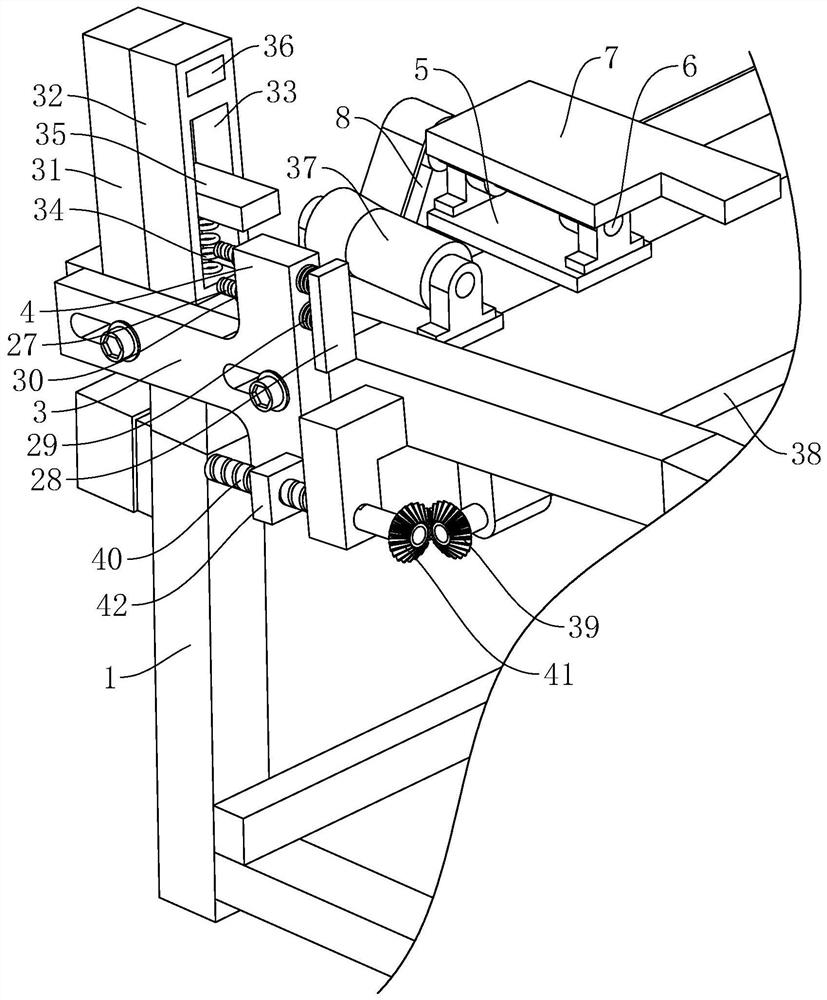

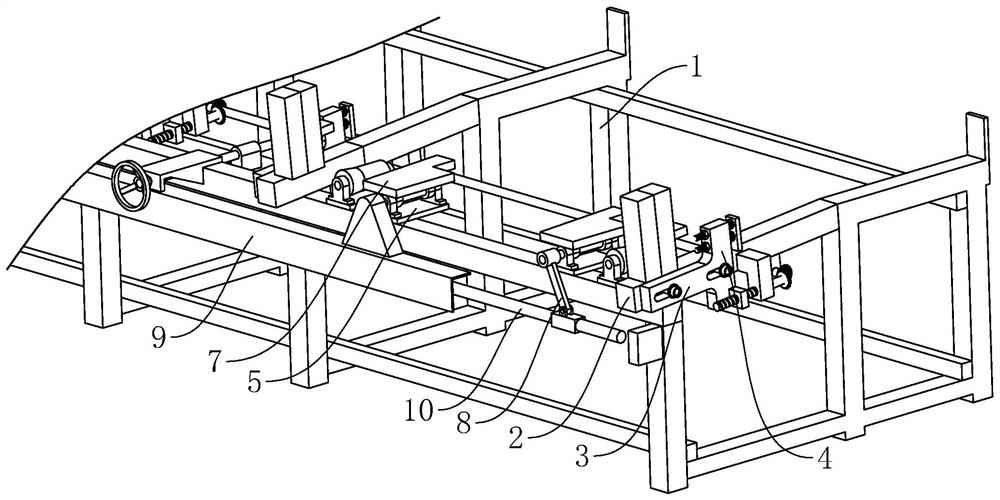

[0039] Attached to the following Figure 1-7 This application will be described in further detail.

[0040] The embodiment of the present application discloses a bar supply device for a cutting machine. refer to figure 1 , The bar feeding device for cutting machine includes a frame 1, a discharging frame 2 and a feeding mechanism. The outline of the frame 1 is rectangular, the top of the frame 1 is inclined, and the height of the top of the frame 1 is along the width of the frame 1. The direction is gradually lowered, and both the feeding rack 2 and the feeding mechanism are installed on the top of the rack 1 at a lower height.

[0041] refer to figure 1 and figure 2 , there are several feeding racks 2 arranged along the length direction of the rack 1, and an adjusting plate 3 is installed vertically on one side of the discharging rack 2, and the top of the adjusting plate 3 is close to the top of the rack 1 The higher position is integrally connected with the first posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com