Surface treatment method of piston for quartering hammer

A surface treatment and breaking hammer technology, applied in heat treatment furnaces, heat treatment equipment, coatings, etc., can solve problems such as large brittleness, large grinding allowance, piston failure and scrapping, etc., to improve impact resistance and increase surface area. Hardness, the effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

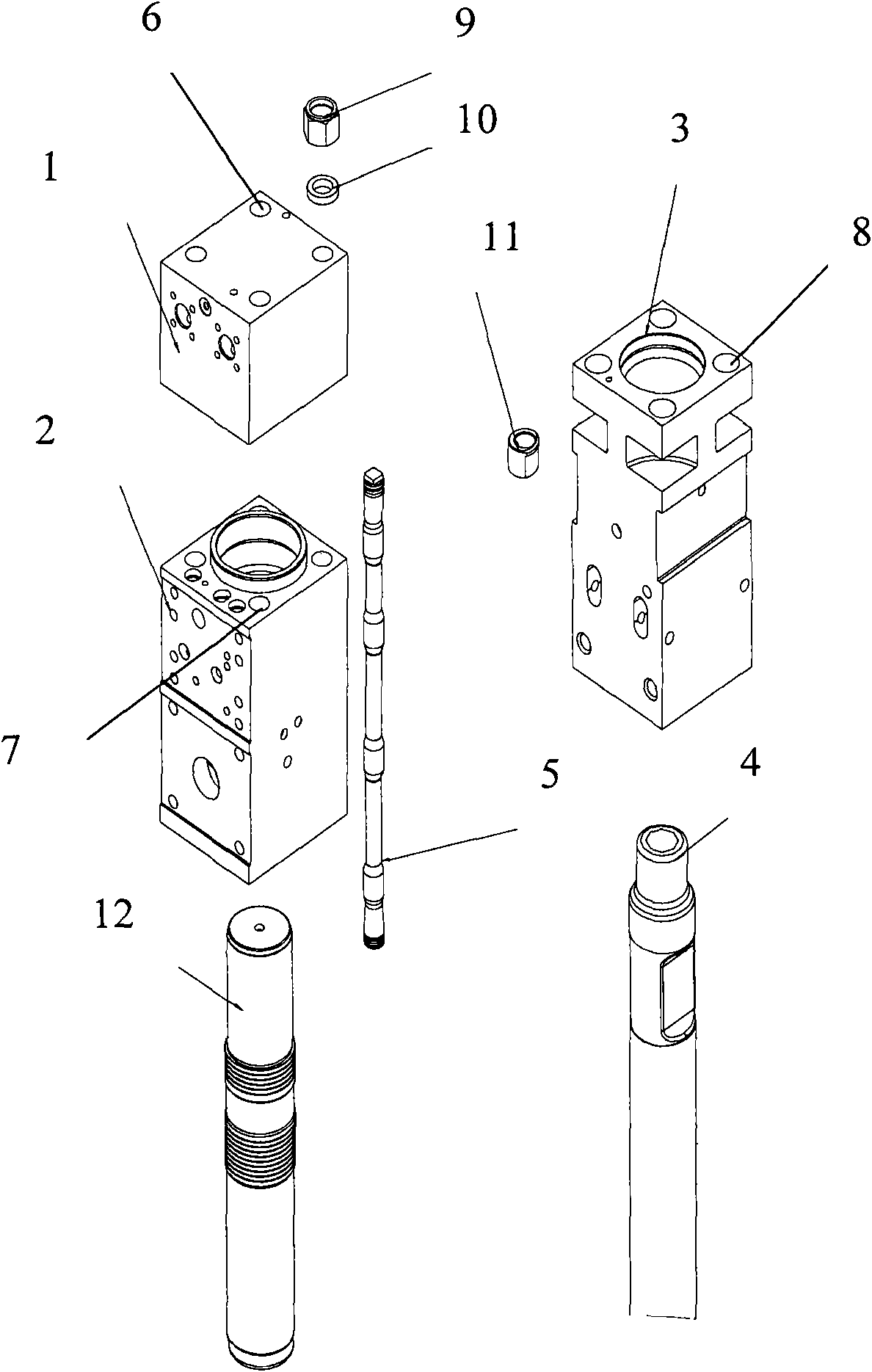

[0017] The surface treatment method for the piston of the breaking hammer provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0018] like Figure 5-Figure 6 and figure 2 As shown, the surface treatment method for the piston of the breaking hammer provided by the present invention includes the following steps in order:

[0019] (1) Firstly, the raw material is forged into figure 2 The rod 9 shown for the piston was then isothermally annealed at a temperature of 650° C. for 30 hours;

[0020] (2) if Figure 5 As shown, the above-mentioned annealed piston rod 9 is roughly machined on a common lathe, and a machining allowance of 2 mm is left on the circumferential surface 12 and the striking surface 13;

[0021] (3) Carburizing the above-mentioned rough-machined piston so that the depth of the carburizing layer reaches 3mm;

[0022] (4) if Image 6 As shown, the above-mentioned carbur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com