Abrasive belt grinding machine

A grinding machine and grinding mechanism technology, applied in belt grinders, grinders, grinding/polishing equipment, etc., can solve the problems of low work efficiency, offset and loss of grinding belt, complex structure, etc., to improve grinding Efficiency, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

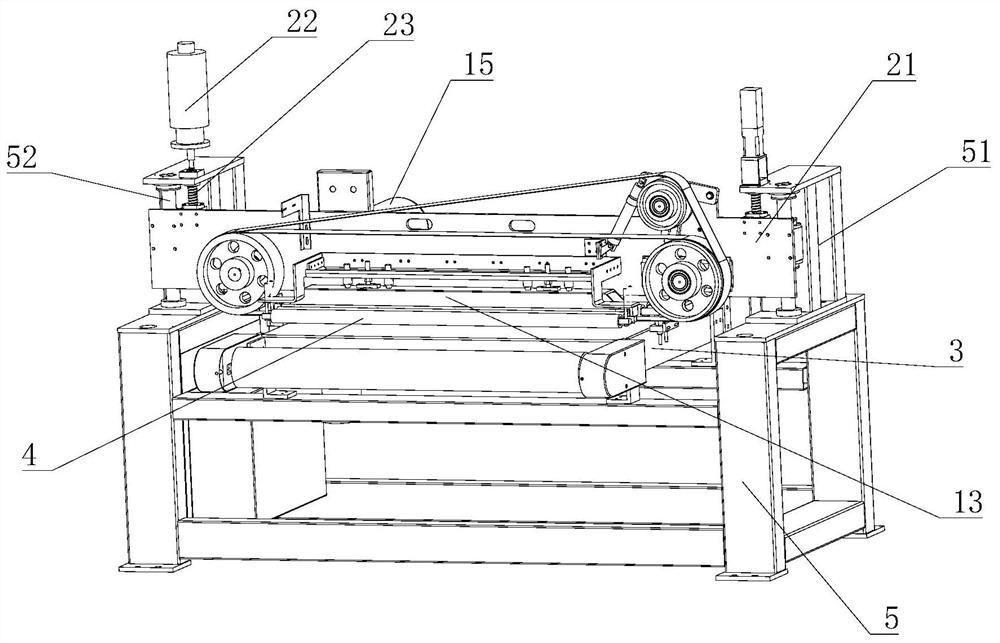

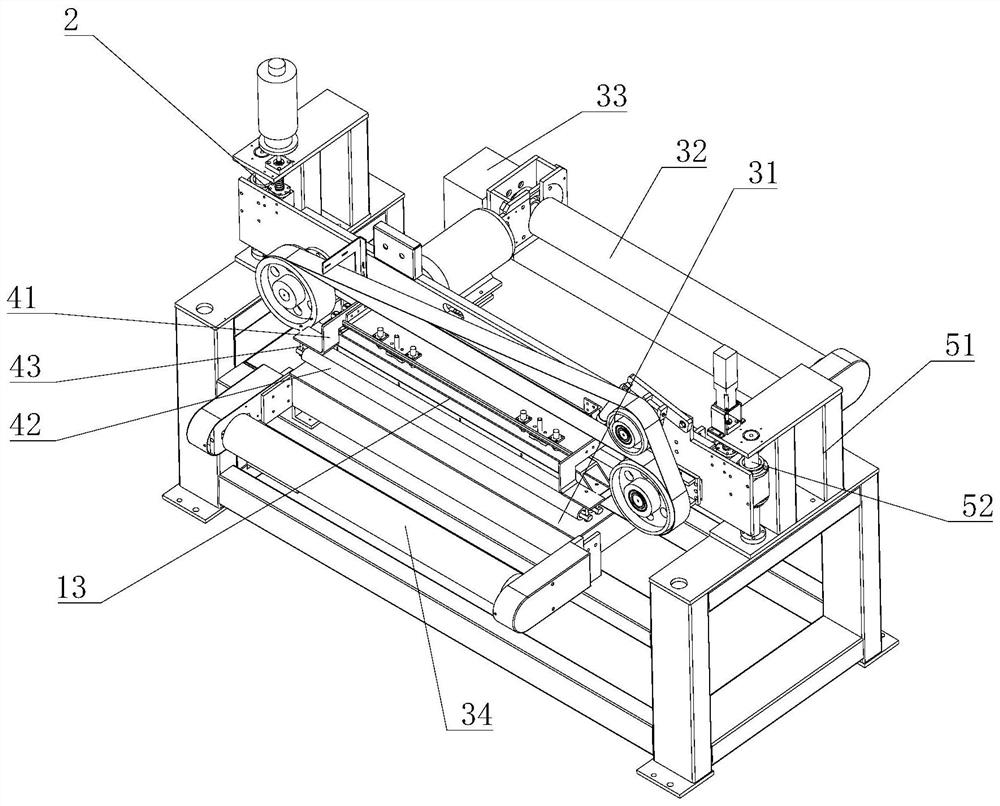

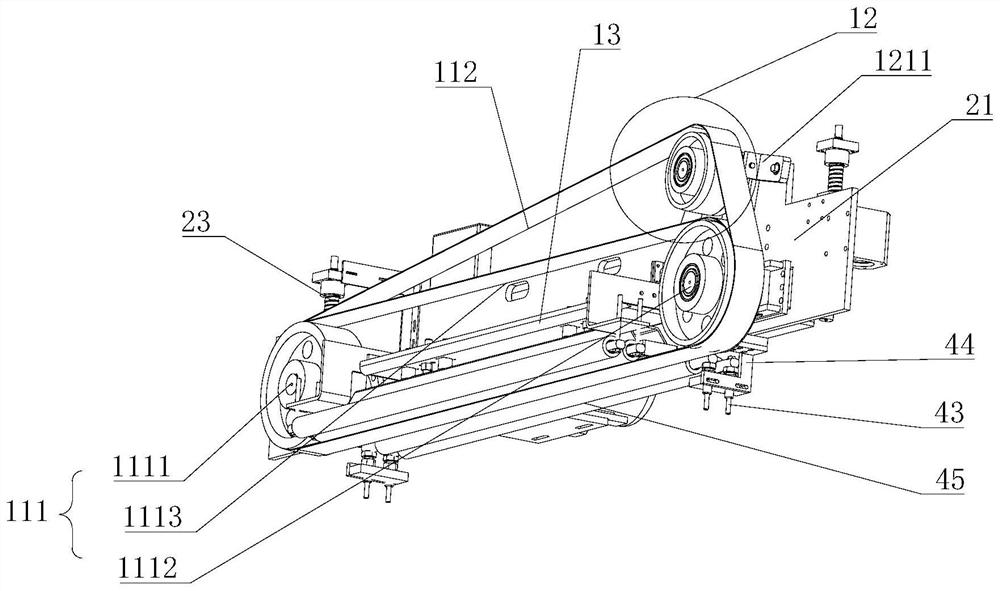

[0023] Abrasive belt grinding machine provided by the invention, concrete technical scheme is as follows:

[0024] The abrasive belt grinder includes an adjustment mechanism 2, a grinding mechanism 1 and a transmission mechanism 3, wherein the adjustment mechanism 2 drives the grinding mechanism 1 to move up and down. The adjusting mechanism 2 includes a mounting plate 21 and an adjusting motor 22, and the adjusting motor 22 drives a screw rod 23 to drive the mounting plate 21 to move up and down. The adjusting motor 22 is a servo motor, and the mounting plate 21 is connected with the screw rod 23 , and the screw rod 23 converts the circular motion of the adjusting motor 22 into the linear motion of the mounting plate 21 . The grinding mechanism 1 is installed on the mounting plate 21 , and as the mounting plate 21 moves, the position of the grinding mechanism 1 also changes accordingly. The grinding mechanism 1 includes a driving assembly 11 and a replacement assembly 12. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com