A top drive core drilling rig

A core drilling rig and top drive technology, applied in rotary drilling rigs, rotary drilling, percussion drilling, etc., can solve problems such as difficulty in realizing integrated control, low work efficiency, and limited drilling force, and achieve input power transmission The effect of shortening the process, improving work efficiency, and easy integrated control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

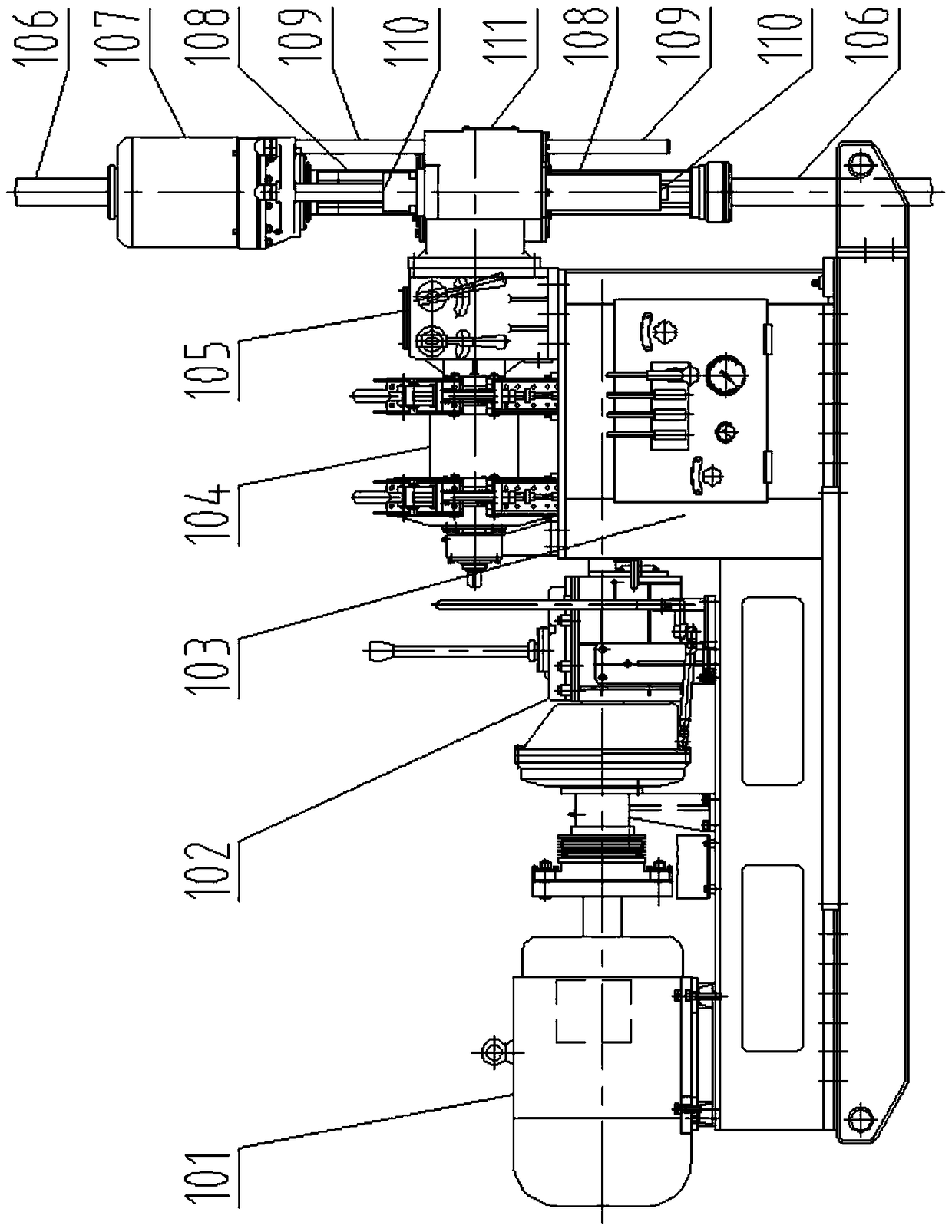

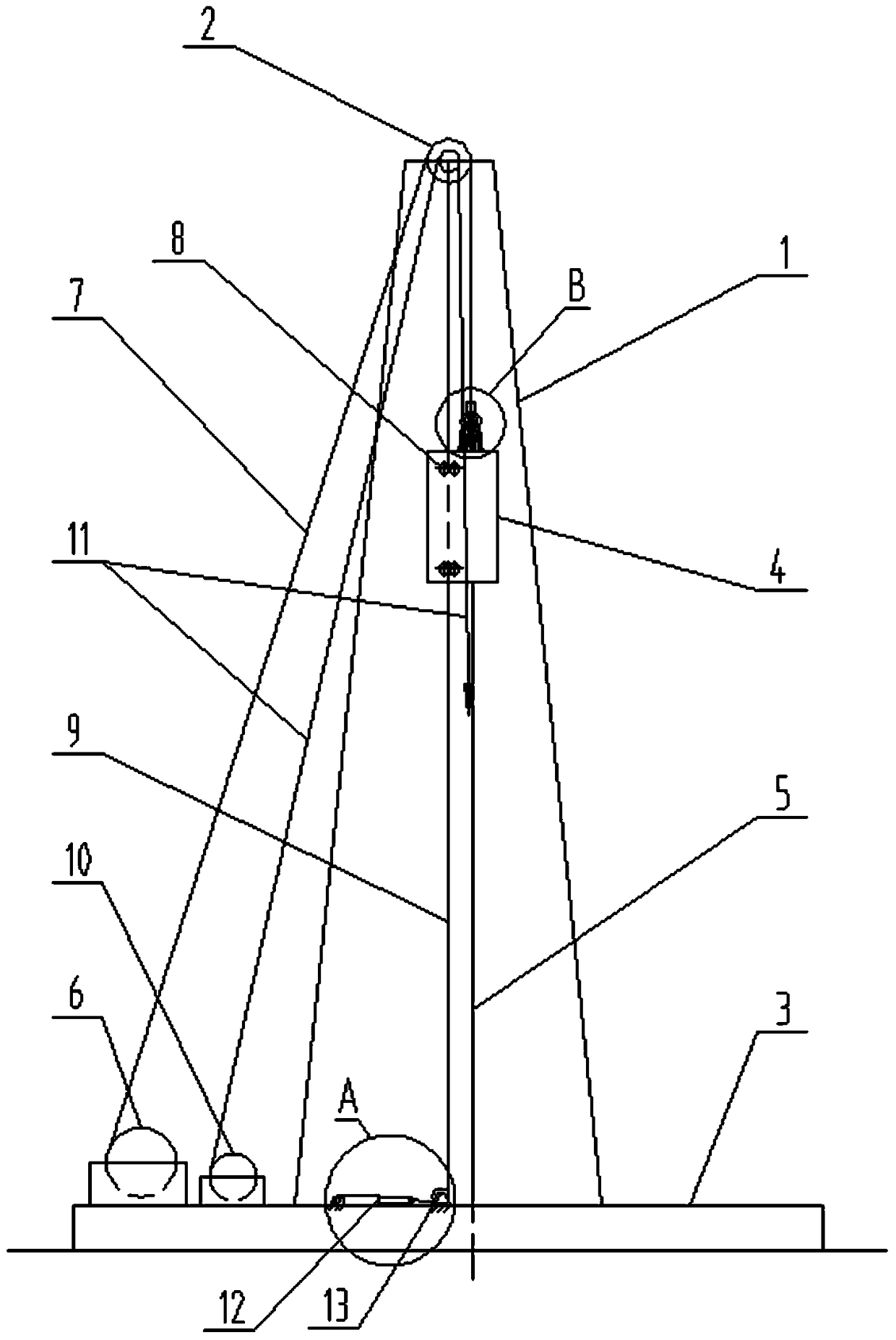

[0031] Such as figure 2 As shown, a top drive core drilling rig includes a drilling tower 1, a tower top pulley block 2, a tower base 3, an integrated power head 4, a drill pipe 5, a main winch 6, a main suspension rope 7, a guide pulley 8 and a guide Rope 9; the tower top pulley block 2 is located at the top of the drilling tower 1, the main suspension rope 7 protrudes from the main winch 6, passes through the tower top pulley block 2 and is connected with the integrated power head 4; the guide rope 8 is located on both sides of the integrated power head 4 side, its upper and lower ends are fixedly connected to make it tight; the guide pulley 9 is installed on both sides of the integrated power head 4, and there are two pulleys at the upper end and the lower end of each side, and these two pulleys are arranged in parallel, and the guide rope 8 Sandwiched between the two pulleys; the top drive core drilling rig also includes an auxiliary winch 10 and an auxiliary lifting rope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com