Gap residual residual sand separation type crystal brick sand blasting device

A sandblasting device, a separate technology, is used in explosion generating devices, used abrasive treatment devices, spray guns, etc. Abrasion-free, precise sandblasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

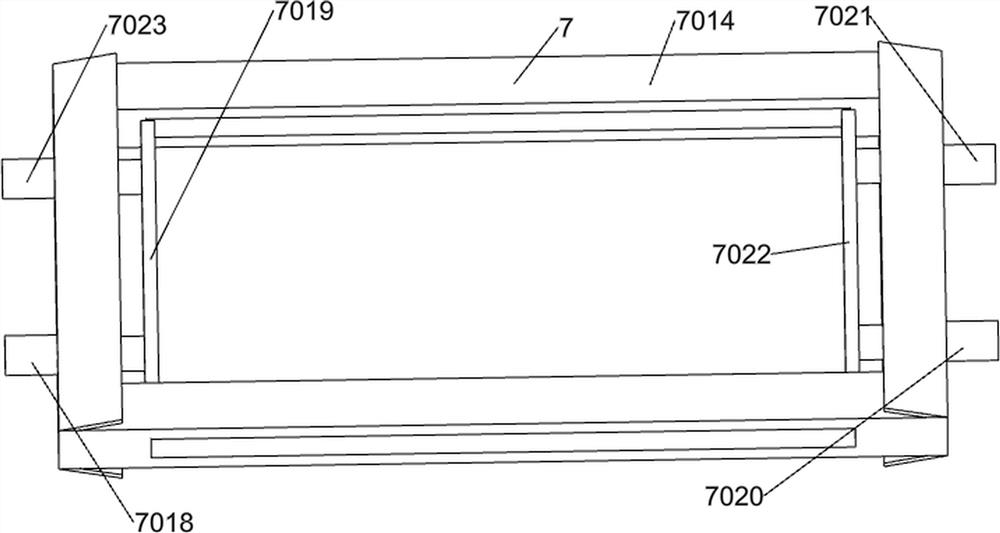

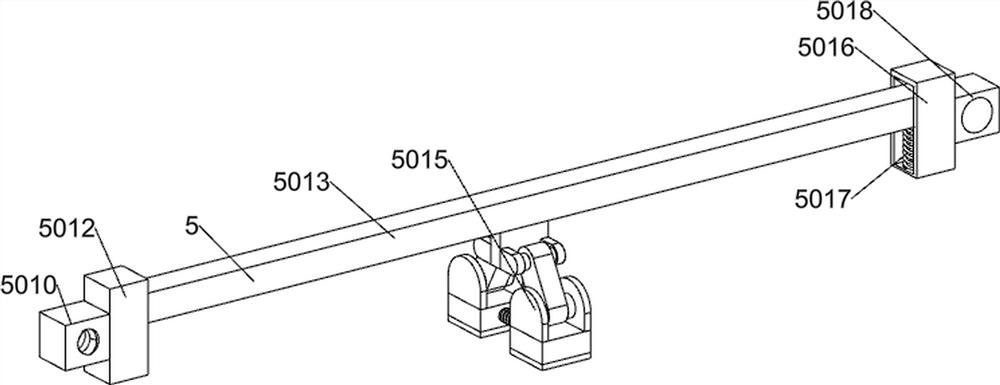

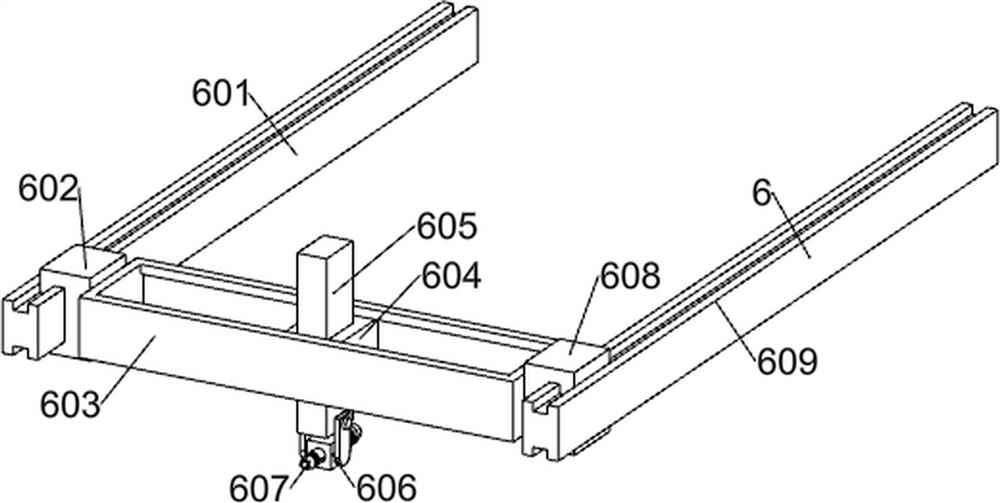

[0033] A sand blasting device for crystal bricks with gap residual sand separation, such as Figure 1-13 As shown, it includes a working machine board 1, a support foot 2, a sandblasting cabin 3, an operation control panel 4, a separation shakeout system 5, a sandblasting system 6, a dislocation sand discharge system 7, a sealed top cover 8, and a collection box 9 , air pump 10, sandblasting power box 11, pipeline fixed deck 12, first air cylinder 13 and second air cylinder 14; the working machine tool plate 1 below is welded with the support foot 2; the working machine tool plate 1 top is connected with sandblasting The cabin 3 is connected by bolts; the sandblasting cabin 3 is connected with the operation control panel 4; the sandblasting cabin 3 is connected with the separated sand blowing system 5; The sand system 7 is connected; the dislocation sand discharge system 7 is connected with the machine tool board 1; the dislocation sand discharge system 7 is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com