Microlite wood profile manufacturing equipment

A technology for manufacturing equipment and profiles, applied in the field of microcrystalline stone wood profile manufacturing equipment, can solve the problems of blocking devices, low efficiency of manufacturing equipment, time-consuming and labor-intensive, etc., and achieve the effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

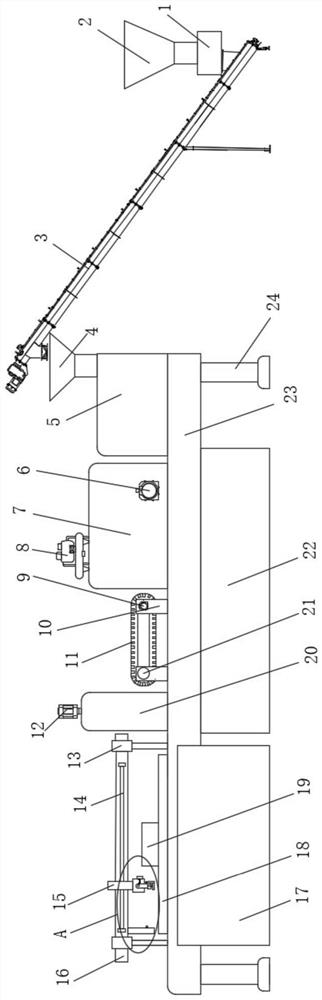

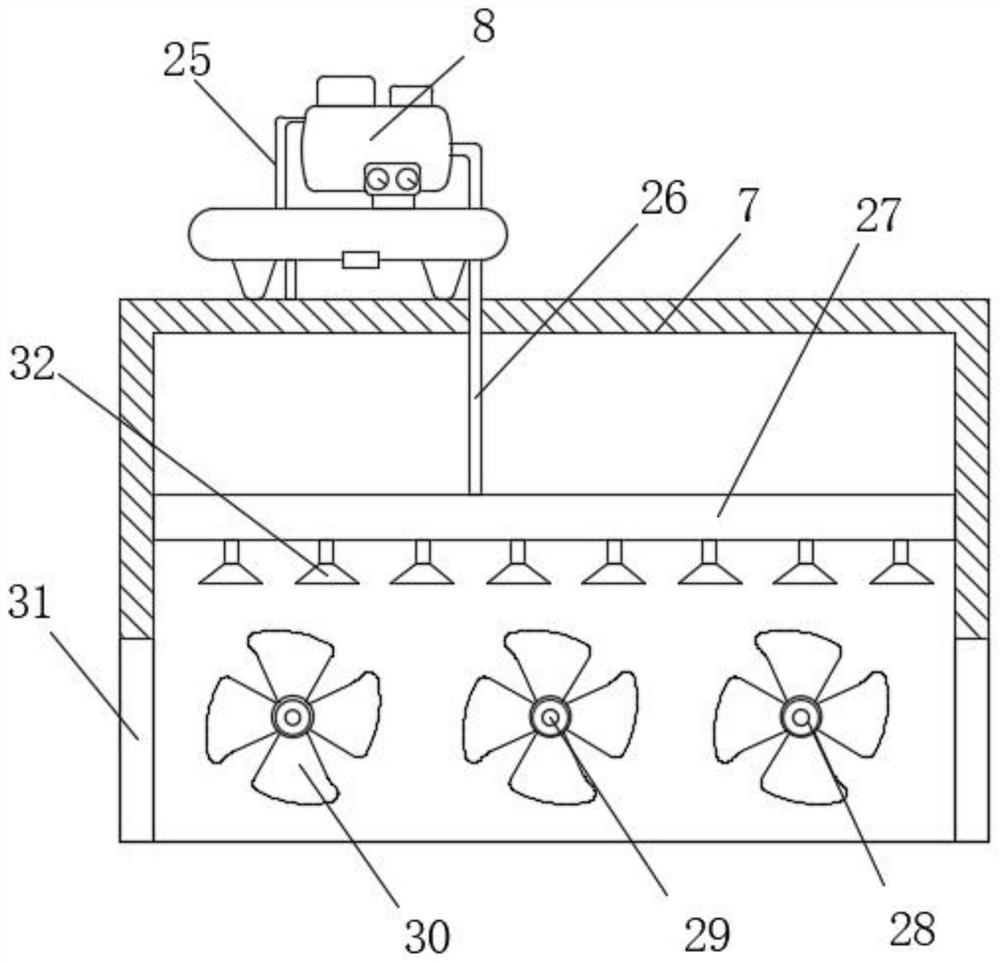

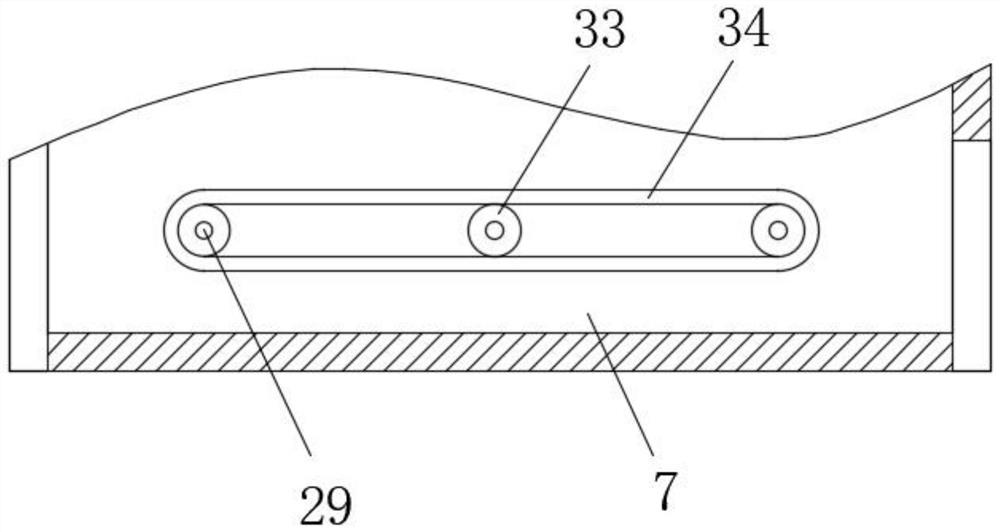

[0038] refer to Figure 1-11 , a microcrystalline stone wood profile manufacturing equipment, including an operating table 23, the bottom of the operating table 23 is fixedly connected with two symmetrically arranged second support columns 24, and the top side of the operating table 23 is fixedly connected with a thermoforming machine 5 , one side of the thermoforming machine 5 is provided with a feeding assembly for feeding, the top of the operating table 23 is fixedly connected with a sizing box 7, and the inside of the sizing box 7 is provided with a sizing assembly for shaping the wood profile, the operating table 23 The top of the top is fixedly connected with two symmetrical four first support columns 10, the outer wall of the first support columns 10 is provided with a traction assembly for pulling wood, the top of the operating table 23 is fixedly connected with a cutting box 20, the inside of the cutting box 20 A cutting assembly for cutting wood profiles is provided,...

Embodiment 2

[0048] refer to Figure 12 , this embodiment is improved on the basis of Embodiment 1: the discharge assembly includes an electric push rod 60 fixedly connected to the top of the console 23, the piston rod of the electric push rod 60 passes through the first fixed plate 19 and is fixedly connected to the push plate 18. The bottom of the push plate 18 is in conflict with the top of the console 23, and one side of the console 23 is provided with a receiving box 17, and the electric push rod 60 is electrically connected to the first photoelectric switch 61.

[0049] The beneficial effects of this embodiment are: the first photoelectric switch 61 can be triggered, and then the electric push rod 60 can be started. Avoid manually pushing wood profiles, realize the cutting process, reduce the workload of workers, and improve work efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com