High-rise intelligent compact shelf and goods taking method

A dense rack and intelligent technology, applied in the field of dense racks, can solve the problems of inconvenient searching for goods and low efficiency of picking up, and achieve the effect of improving the stability of goods transmission, improving the efficiency of picking up, and reducing labor input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

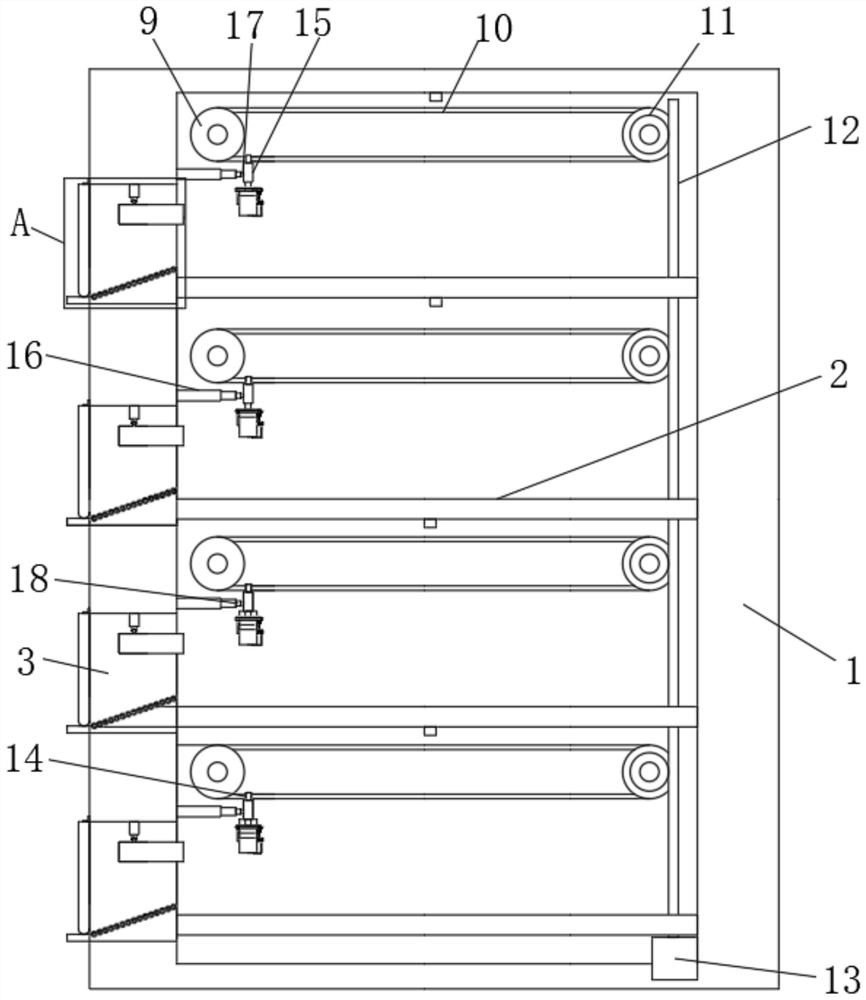

[0044] Embodiment one, by Figure 1 to Figure 7 Given, the present invention comprises compact shelf body 1, and the inner equidistant of compact shelf body 1 is provided with placement board 2, and the inner top end of compact shelf body 1 and the middle position of the bottom end of placement plate 2 are all provided with camera, compact shelf body 1 One side of the discharge port 3 is equidistantly provided with a discharge port 3, and the inner bottom end of the discharge port 3 is provided with a deflector 4 on one side of the discharge port 3. Through the design of the deflector 4, it is convenient for the goods to slide out, and then To speed up the take-out of goods, the compact rack body 1 is provided with a sealing plate 5 located on one side of the discharge port 3. It should be noted here that the sealing plate 5 and the camera are electrically connected to the external controller, and the controller controls the sealing plate 5. Opening and closing, the inner top ...

Embodiment 2

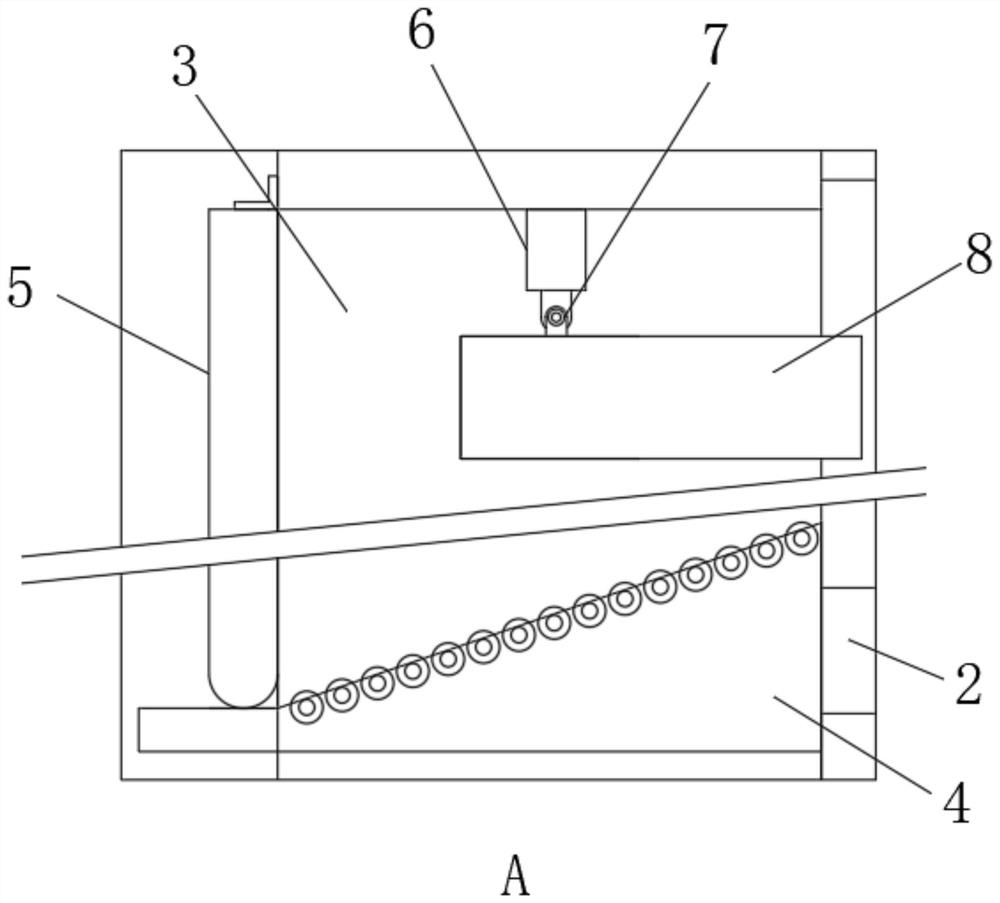

[0045] Embodiment two, on the basis of embodiment one, by figure 1 and figure 2 Given, the top of the diversion table 4 is equidistantly equipped with transmission rollers, and one end of the diversion table 4 is provided with a placement platform connected to the sealing plate 5, through the design of the diversion table 4, it is convenient to realize the sliding of goods, and through the transmission The design of the roller speeds up the sliding speed and reduces the frictional force at the same time. Through the design of the placing platform, it is convenient to place the goods on the placing platform, avoiding the falling of the goods, and then realizing the protection of the goods.

Embodiment 3

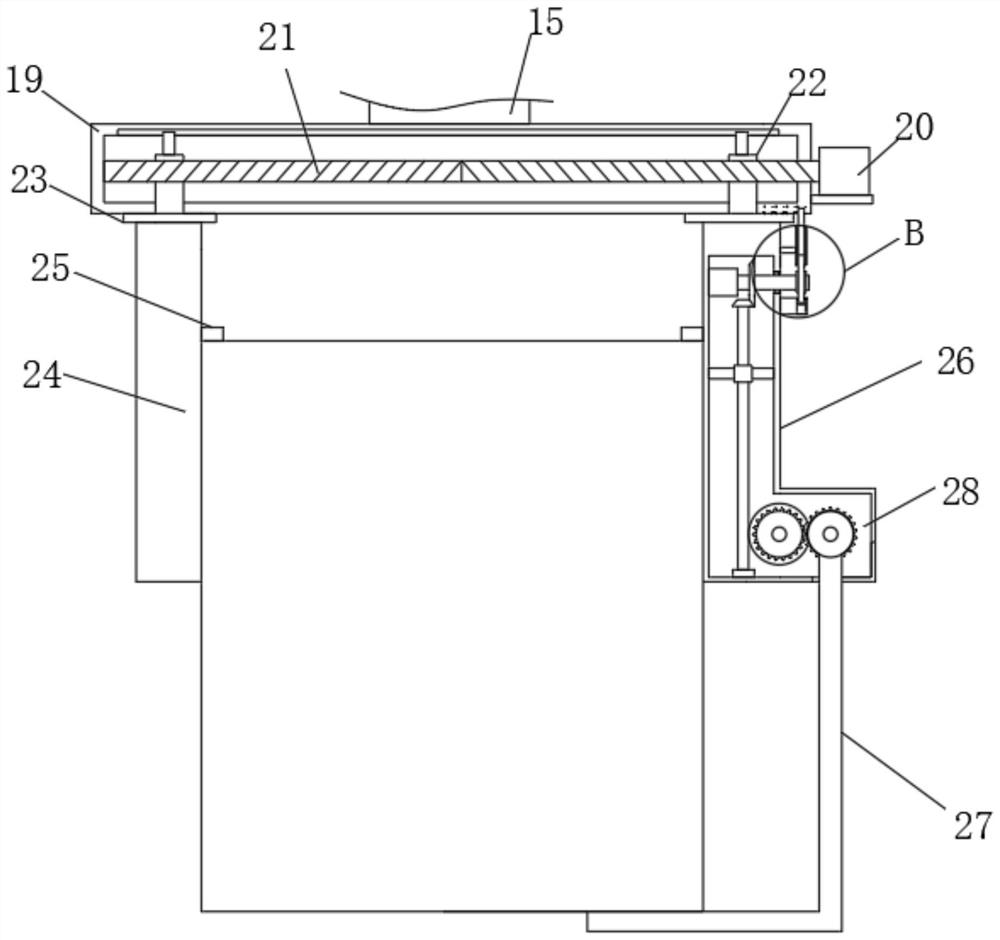

[0046] Embodiment three, on the basis of embodiment one, by figure 1 and image 3 Given, clamping mechanism two comprises fixed box 19, motor three 20, two-way screw mandrel 21, slide block 22, slide plate 23, clamping plate one 24, touch switch two 25, clamping plate two 26, support plate 27 and Driver, fixed box 19 is installed on the output shaft bottom end of electric telescopic rod two 15, and one side of fixed box 19 is provided with motor three 20, and the output shaft of motor three 20 is connected with the two-way screw rod 21 that is positioned at fixed box 19 inside, two-way Symmetry is provided with slide block 22 on the screw mandrel 21, and the bottom end of slide block 22 is provided with the slide plate 23 that is positioned at fixed box 19 outer bottoms, and wherein the bottom end of one slide plate 23 is provided with clamping plate one 24, and wherein the other slide plate 23 The bottom end is provided with clamping plate 2 26, and the bottom of clamping pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com