Vertical wind tunnel model pitching-rolling test device and use method

A test device and wind tunnel test technology, which is used in measurement devices, aerodynamic tests, aircraft component testing, etc., can solve the problem of wingtip vortex development interference, large damage to the aerodynamic shape of flying-wing aircraft, and poor adaptability to different models of support devices. and other problems, to achieve the effect of high rotation accuracy, high simulation accuracy and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

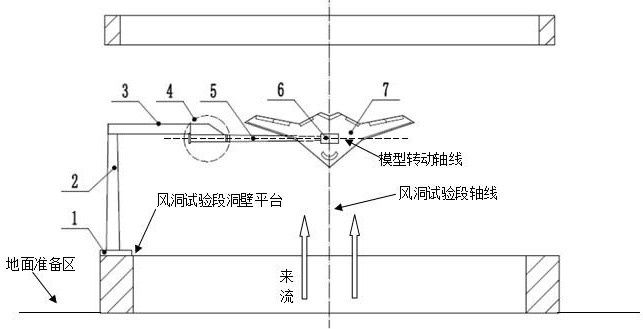

[0050] Embodiment 1 of the present invention provides a vertical wind tunnel model pitch-roll test device, wherein the test device includes:

[0051] A base 1, the base 1 is fixedly installed on the wall platform of the vertical wind tunnel test section;

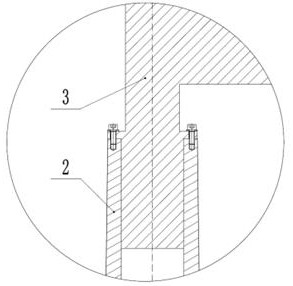

[0052] A column 2, the bottom end of the column 2 is fixedly connected to the base 1;

[0053] A support rod 3, the support rod 3 is located between the upright column 2 and the abdominal support bending rod 5, one end of the support rod 3 is fixedly connected to the top of the upright column 2, and the other end is connected to the abdominal support through the rotating assembly 4 One end of the curved rod 5 is connected, and the axis of the support rod 3 is parallel to the diameter direction of the wind tunnel test section;

[0054] The rotating assembly 4 is installed on the end of the support rod 3 away from the column 2;

[0055] The belly brace bending rod 5 is fixedly connected to the mounting base 6 at the end far ...

Embodiment 2

[0086]Embodiment 2 of the present invention also provides a method for using a vertical wind tunnel model pitch-roll test device, such as Figure 10 As shown, the usage steps are as follows:

[0087] Step S10: Install the base 1 on the wall platform of the vertical wind tunnel test section, and adjust the direction and level of the base 1;

[0088] Step S20: installing the column 2 on the base 1, and adjusting the direction and verticality of the base 1;

[0089] Step S30: Insert the rotating part 32 of the support rod 3 into the top of the column 2, add lubricating grease between the contact surface of the rotating part 32 and the column 2 to reduce friction, and rotate the support rod 3 above the ground so that The support rod 3 is located outside the wind tunnel test;

[0090] Step S40: install the rotating assembly 4 on the front end of the supporting part 31; place the electromagnetic brake 41, the magnetic grid assembly 42, the deep groove ball bearing 43, and the stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com