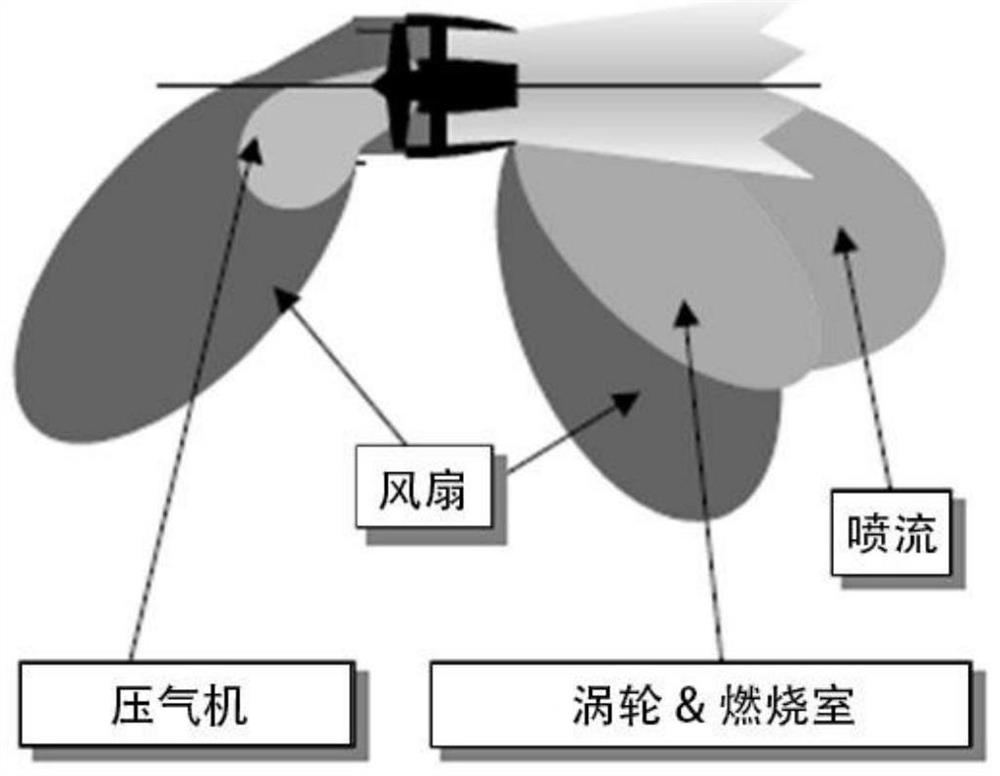

Directivity identification method for noise sources of engine and parts thereof

A noise source and directivity technology, applied in direction finders using ultrasonic/sonic/infrasonic waves, systems for determining direction or offset, and electrical devices, etc. Poor and other problems, to achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

[0060] The present invention is a method for identifying the directivity of the noise source of the engine and its components, and the specific steps are as follows:

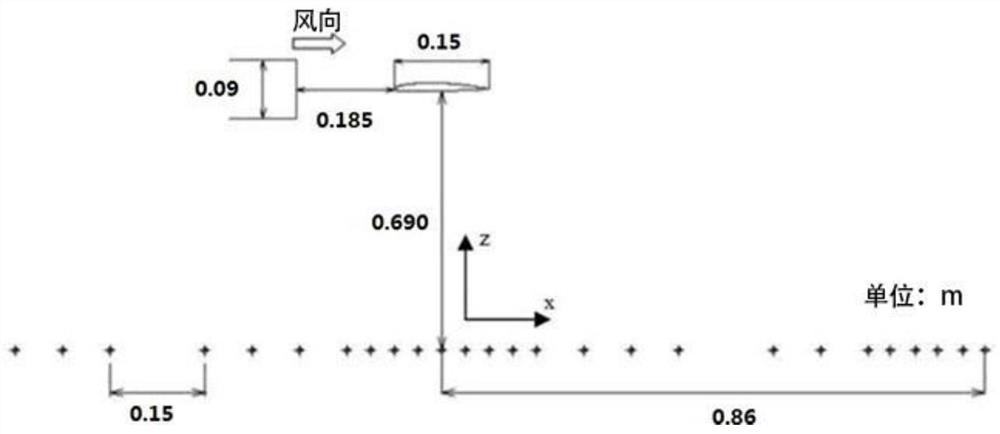

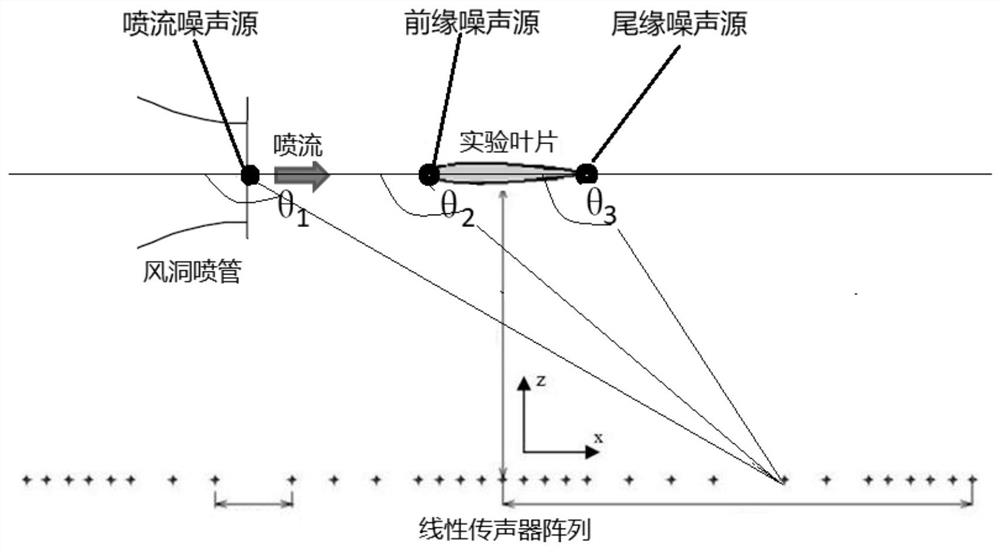

[0061] Step 1: If figure 2 As shown, assuming that the noise source measured in the experiment is a linearly distributed noise source, and the number of noise sources is J, a linear array composed of M microphones placed parallel to the straight line direction of the sound source is used for sound source noise identification measurement, and the microphone array experiment is obtained The measurement data, in which the microphone array arrangement is obtained by computer simulation design according to the distribution of different sound sources.

[0062] assumed is the noise signal measured by the nth microphone, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com