Partition rectifying tower for separating mixed fractions of C8-C11 n-alkanes

A C8-C11, clapboard rectification column technology, applied in the field of clapboard rectification column structure, can solve the problem that the product precision cannot be output according to the predetermined value, etc., achieves good promotion value, unique creativity, and high yield of finished products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention can be explained in more detail by the following examples, the present invention is not limited to the following examples, the purpose of disclosing the present invention is intended to protect all changes and improvements within the scope of the present invention;

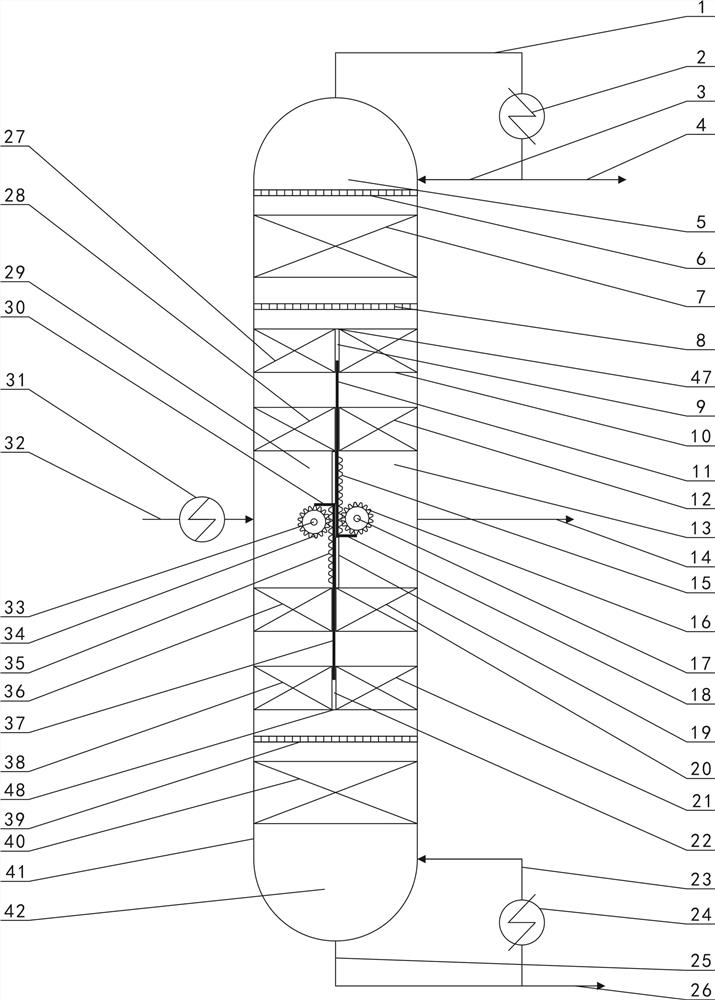

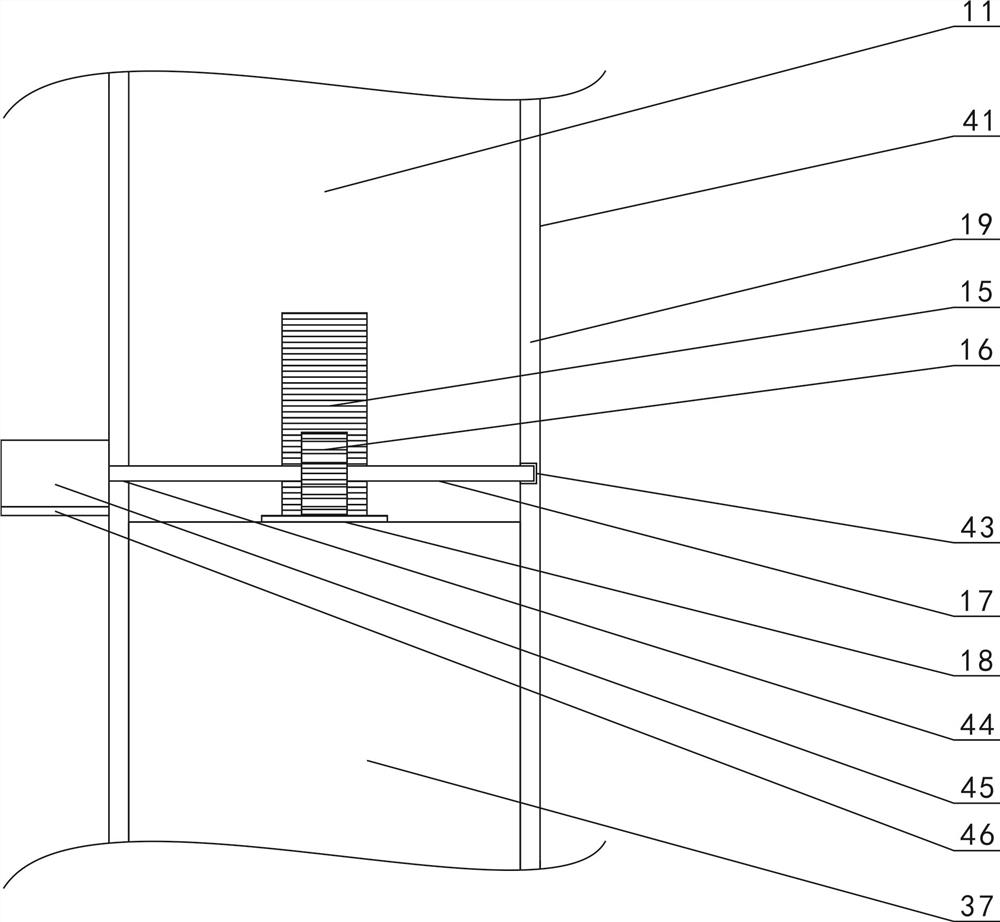

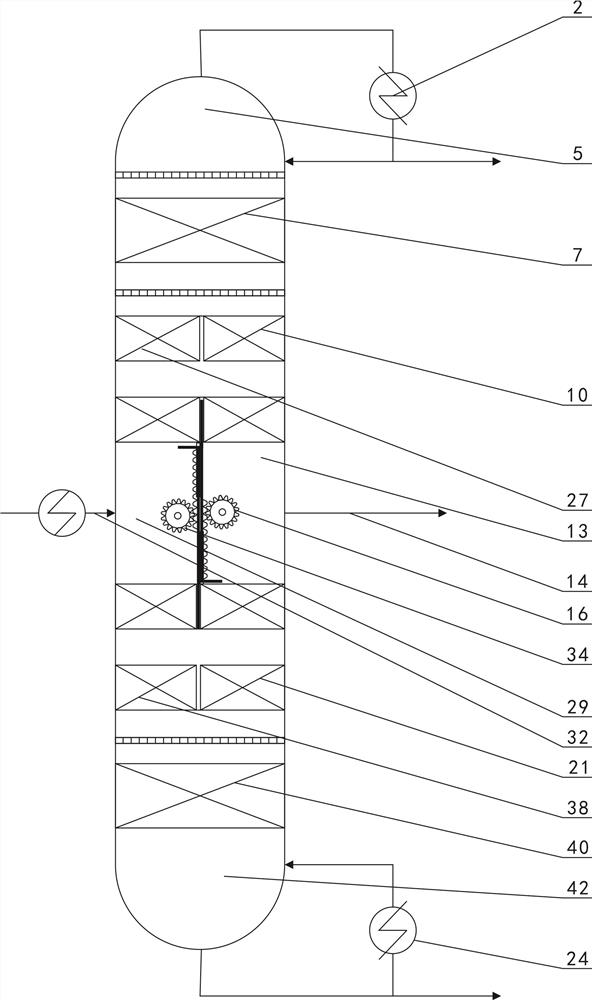

[0022] combined with figure 1Or the clapboard rectification tower for the separation of C8-C11 n-paraffin mixed fractions described in 2, comprising a tower body 41, a chamber is provided in the tower body 41, and a vertical partition is provided in the middle of the chamber , the cavity is divided into four parts, the cavity above the partition forms a common rectification section 5, the cavity below the partition forms a common stripping section 42, and the cavity on one side of the partition forms a rectification inlet Material section 29, the cavity on the other side of the dividing plate forms the middle side line production section 13, the dividing plate comprises dividing plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com