Anti-tearing dust collecting cloth bag of polyester needled felt support

A felt support and anti-tearing technology, which is applied in membrane filters, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as environmental pollution, tearing hidden dangers, bag shaking, etc., and achieve improved tear resistance , Improve the support stability and prevent leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the objects, technical solutions, and advantages of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings. It should be understood that these descriptions are merely exemplary and are not to limit the scope of the invention. Further, in the following description, a description of known structures and techniques is omitted to avoid unnecessary obscuring the concepts of the present invention.

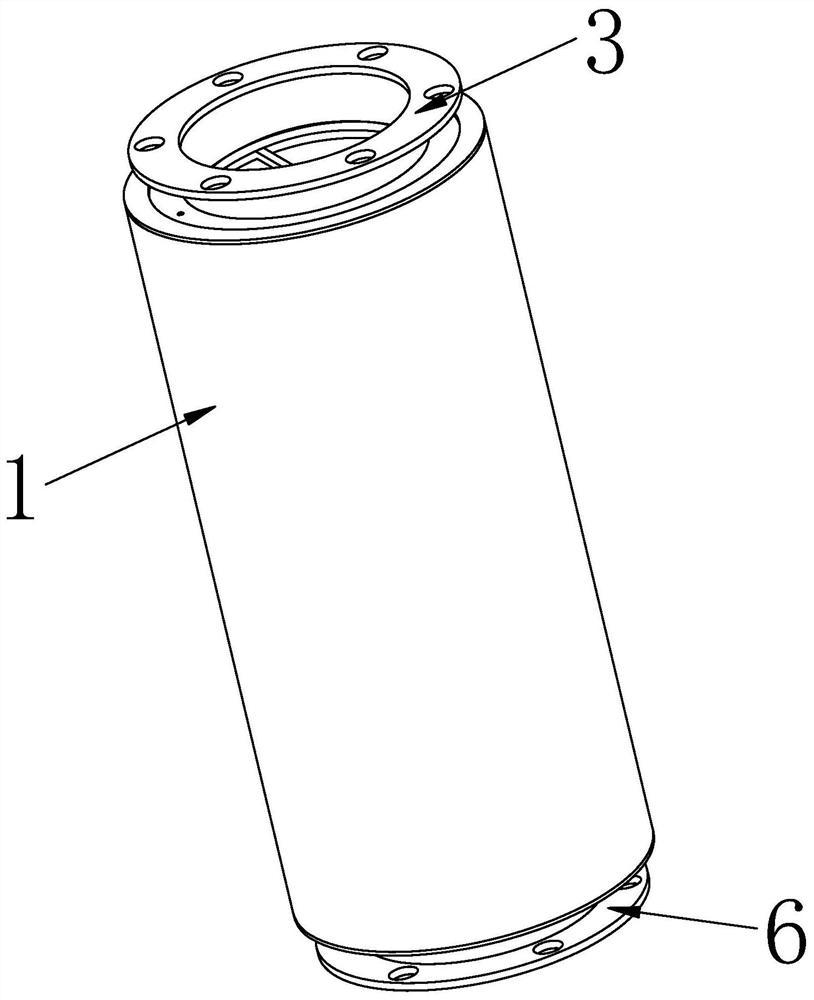

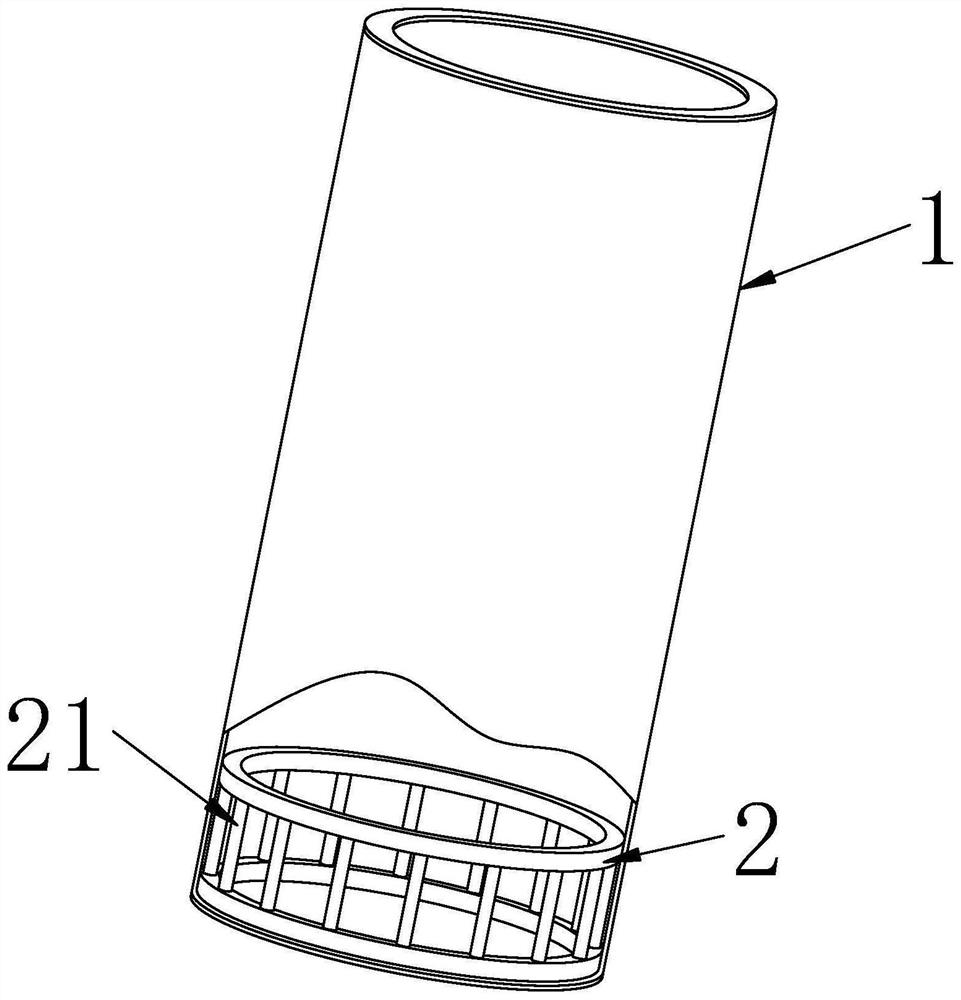

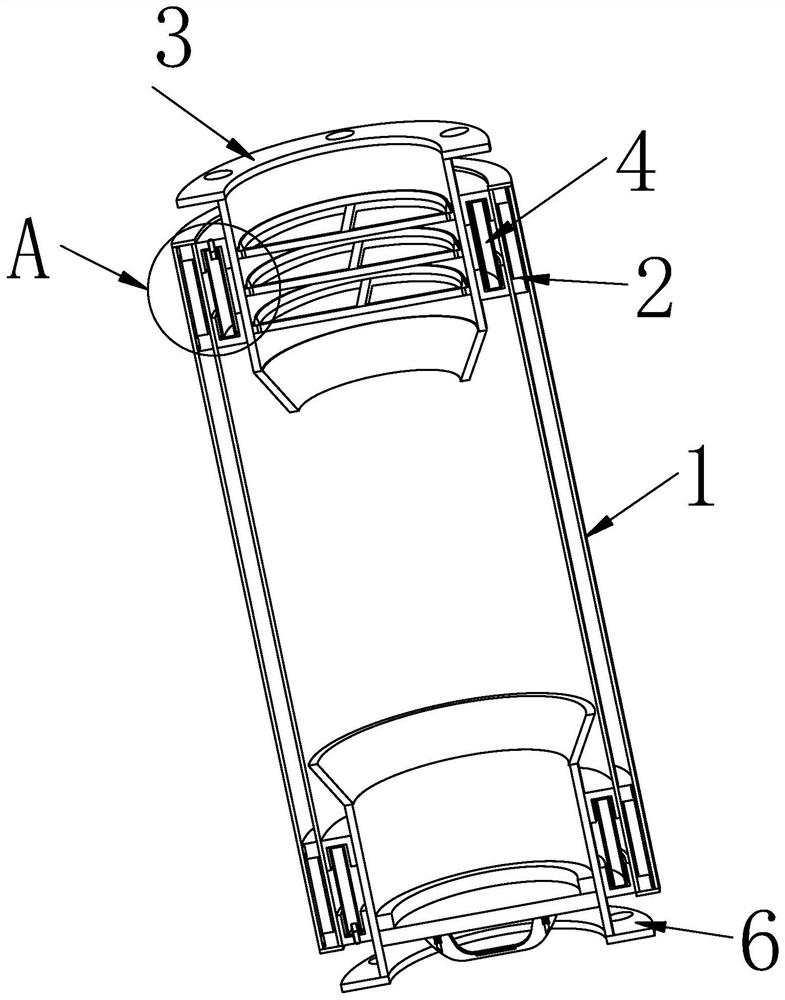

[0026] like Figure 1-4 As indicated, a polyester needle stab felt holder, including a bag body 1, a bobbin 2 in the air end of the bag body 1 and an air end frame 2, and an input support is provided. 3, the outer ring frame 2 is provided with an output support 6, the ring frame 2 is a double layer structure, and several vertical rods 21 are connected between the upper ring plate and the lower ring plate, two ring frame 2 pairs of bags 1 The intake end and the extra gas end are supported as the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap