Magnetically-excited magnetic-conductive high-viscosity glue trace-distribution device and method

A dispensing device and magnetic excitation technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of inconvenient regulation and low precision, and achieve the effects of simple structure, improved distribution precision and promotion of development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

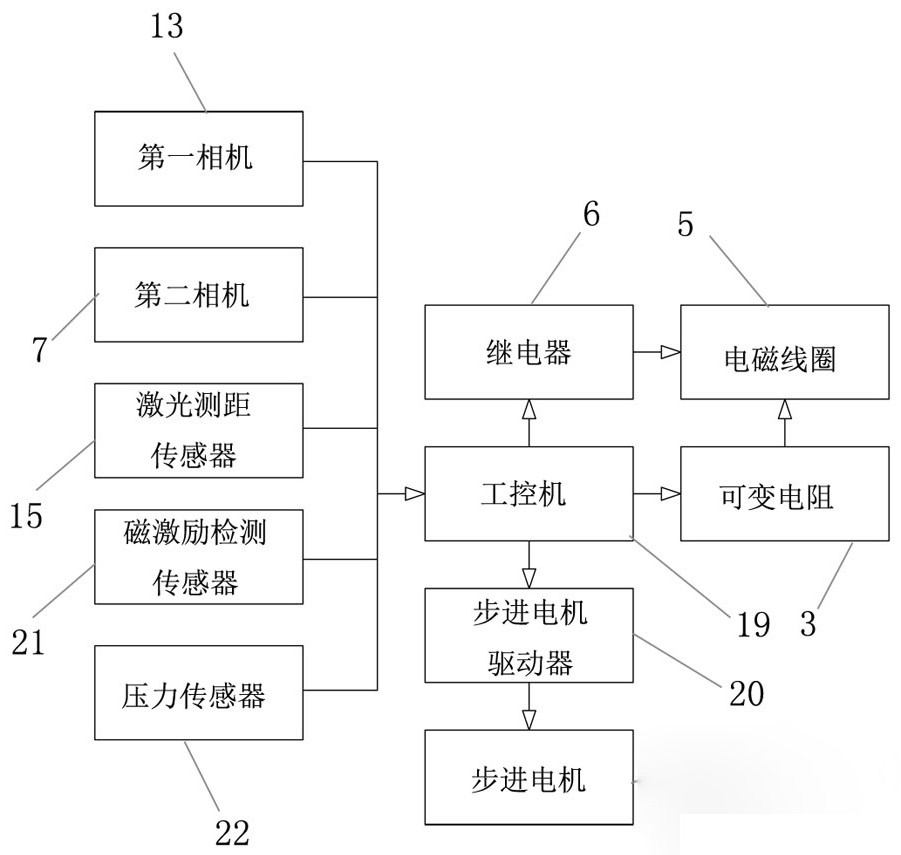

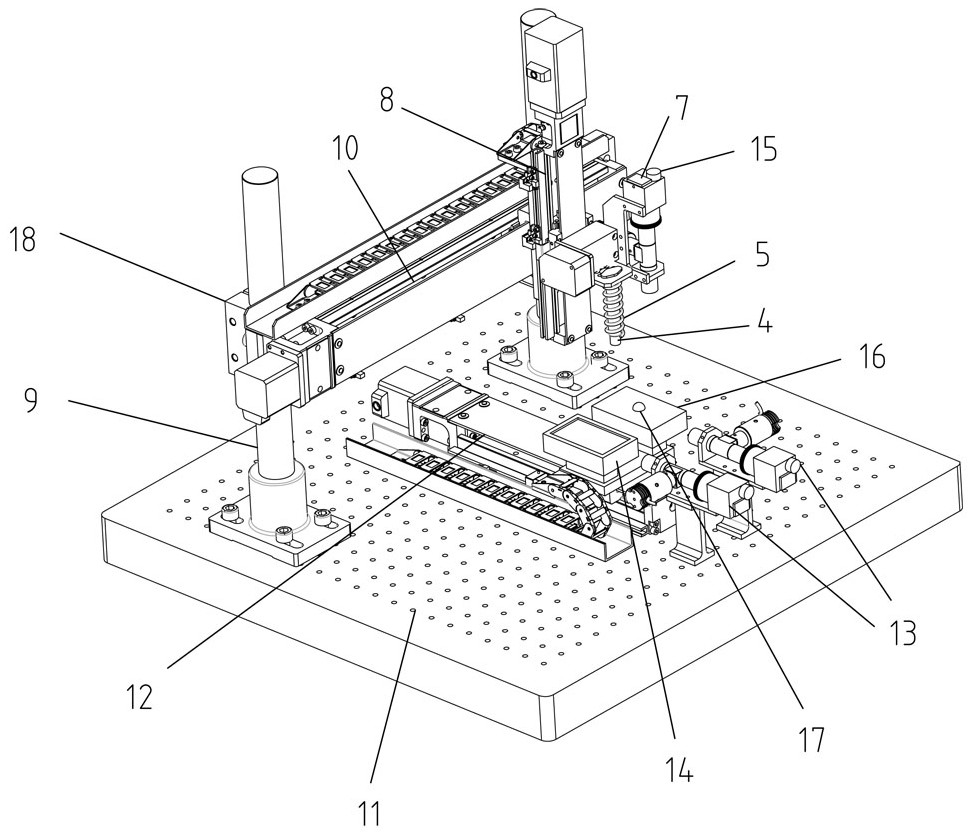

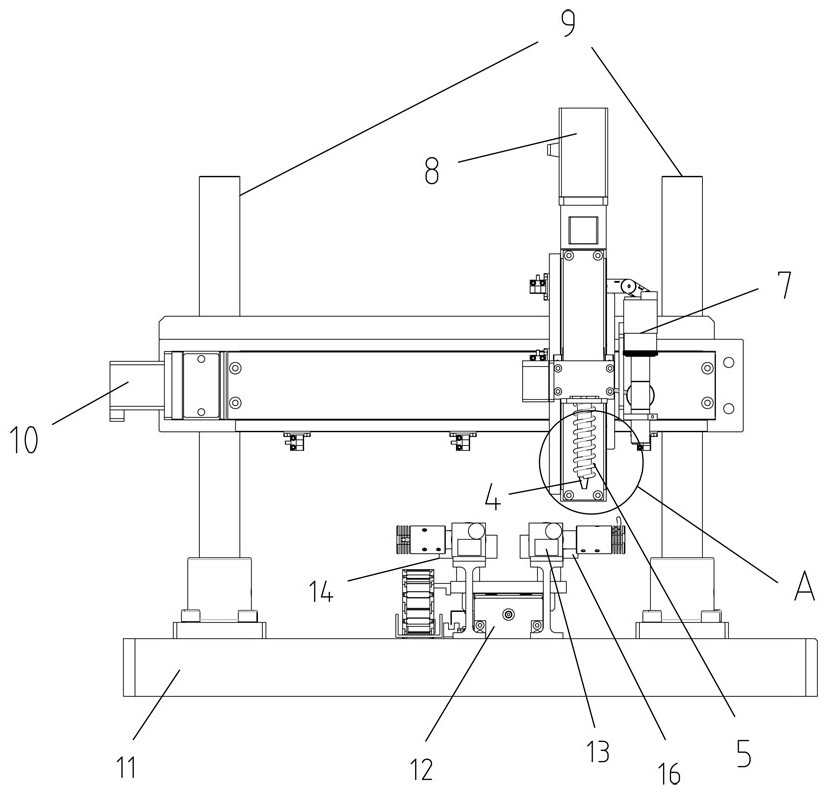

[0053] The first aspect of the present invention proposes a micro-dispensing device for magnetically actuated magnetically permeable high-viscosity glue liquid such as figure 1 As shown, it includes a dispensing mechanism and a mobile platform for driving the dispensing mechanism to perform operations. The dispensing mechanism includes a dispensing head 4 and an electromagnetic coil 5. The dispensing head 4 is a conical cone made of ferromagnetic material. structure, the dispensing mechanism is provided with a control module;

[0054] The control module is used to adjust the magnetic excitation intensity of the dispensing mechanism, and the control module is provided with an industrial computer 19, and the industrial computer 19 setting program is used to divide the gear position of the dispensing mechanism for micro-adsorption of magnetically conductive high-viscosity glue liquid according to the magnetic excitation intensity ;

[0055] The control module is connected with a...

Embodiment 2

[0059] Based on the above-mentioned embodiments, in order to make the dispensing mechanism move accurately so that the dispensing mechanism can complete the adsorption and transfer of magnetically conductive high-viscosity glue, the mobile platform is optimized, such as Figure 1~4 Shown specifically:

[0060] The Y-axis moving unit includes a first directional slide 12, the guide rail of the first directional slide 12 is fixed to the platform 11 by bolts, and the slide block of the first directional slide 12 is provided with a glue storage pool 14 and The workbench 16, the glue storage pool 14 and the workbench 16 are square plates, the upper end surface of the glue storage pool 14 is provided with a downward groove, the groove is used to store magnetically conductive high-viscosity glue, the glue storage pool 14 and workbench 16 are both detachably connected to the slider of the first directional slide 12, and the glue storage pool 14 and workbench 16 move forward and backwa...

Embodiment 3

[0067] Based on the above-mentioned embodiments, in order to realize the micro-dispensing of magnetically conductive high-viscosity glue, the control module is optimized, specifically:

[0068] The control unit also includes a magnetic excitation detection sensor 21 and a pressure sensor 22, and the industrial computer 19 includes an MCU chip;

[0069] The magnetic excitation detection sensor 21 is used to detect the magnetic excitation intensity generated by the dispensing mechanism, and the magnetic excitation detection sensor 21 is connected with the ADC pin of the MCU chip;

[0070] The pressure sensor 22 is arranged on the lower part of the workbench 16. The pressure sensor 22 is used to detect the pressure of the dispensing mechanism on the workpiece. The pressure sensor 22 is connected to the ADC pin of the MCU chip.

[0071] During operation, the magnetic excitation detection sensor 21 detects the magnetic excitation intensity, and transmits the detection result to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com