Ton bag opening and feeding station

A technology of clamping bags and receiving hoppers, which is applied in the field of ton bag feeding, can solve the problems that the materials in the ton bag cannot be poured out quickly, the material spills, and the dust overflows, so as to meet the requirements of environmental protection, prevent dust from spilling, and work The effect of environmental improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

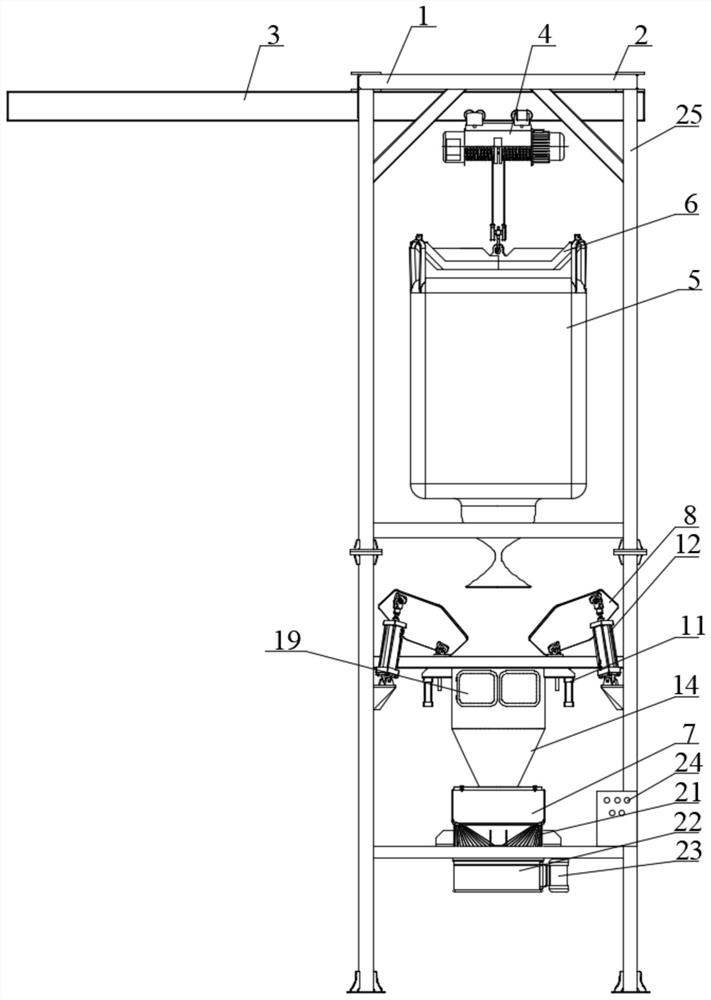

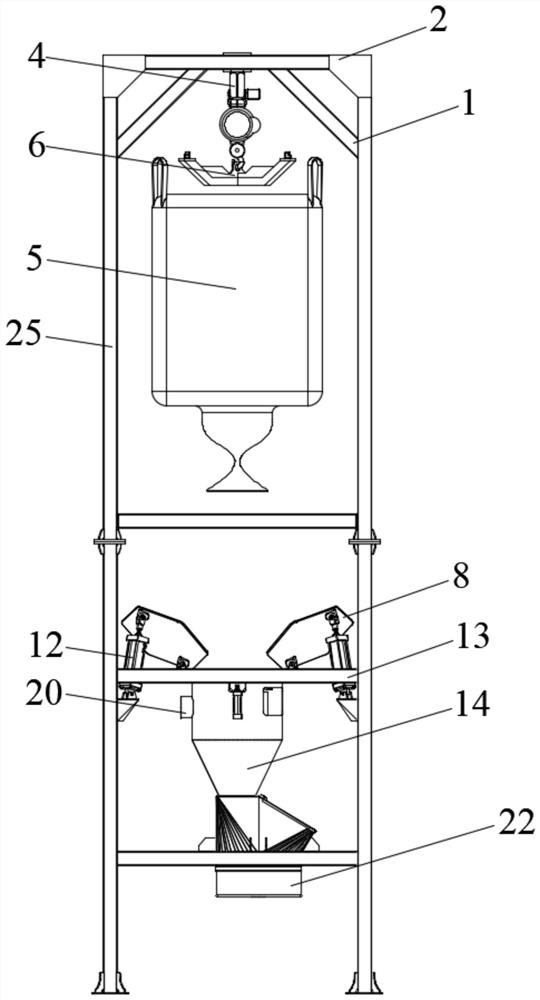

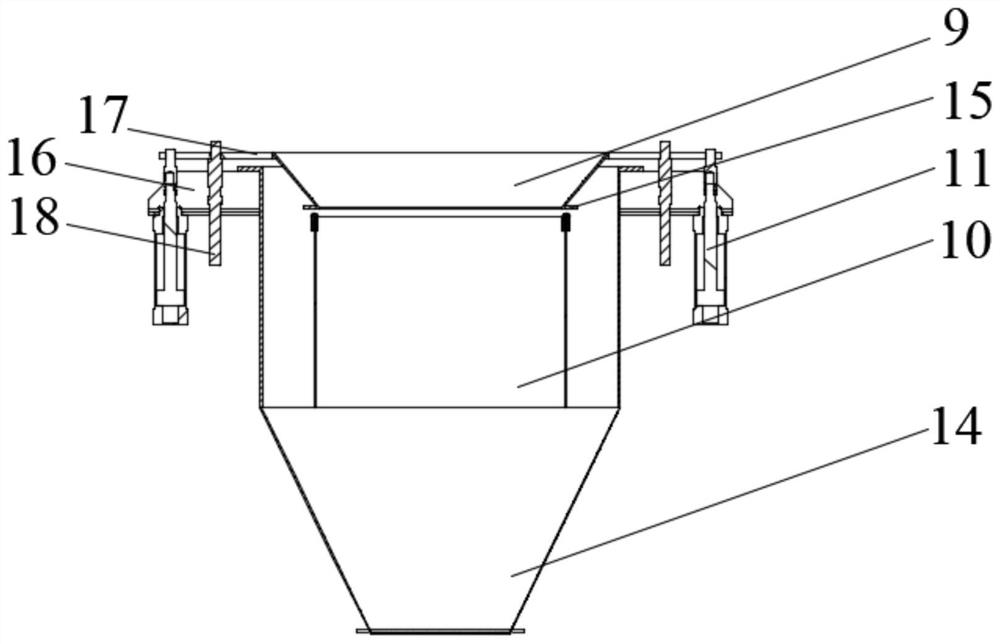

[0019] like Figure 1 to Figure 3 As shown, a ton bag unpacking and feeding station of the present invention includes a frame 1, the top of the frame 1 is provided with a beam 2, and the bottom of the beam 2 is slidably connected with an electric hoist 4 through a guide rail 3, which is used to hook the hoist of the ton bag 5. The hook 6 is connected with the electric hoist 4, the lower part of the frame 1 is provided with a feeding station 7, and the frame 1 is provided with a beating mechanism for beating the tonnage bag 5 under the bag mouth of the ton bag 5. At least one flapping plate 8 on the frame 1, the rack 1 is located below the flapping plate 8 and is provided with a bag clamping mechanism for clamping the mouth of the ton bag 5, and the bag clamping mechanism includes a hopper 9 and a material receiving cylinder arranged up and down. 10 and the clamping cylinder 11 that drives the material receiving hopper 9 to move up and down, and the material receiving barrel 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com