Imbibition oil displacement agent and preparation method thereof

An oil displacement agent and imbibition technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems that the reservoir matrix cannot be contacted for a long time, the viscosity of the system is difficult to maintain stability, and the oil displacement efficiency is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

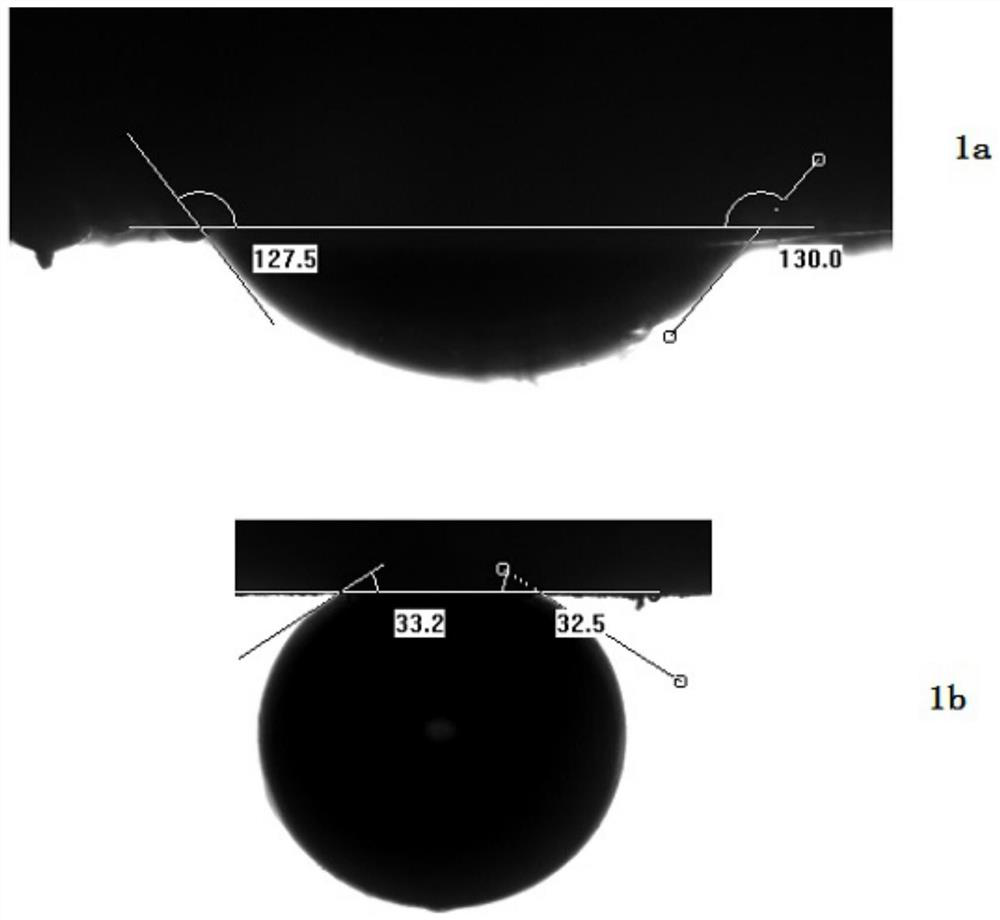

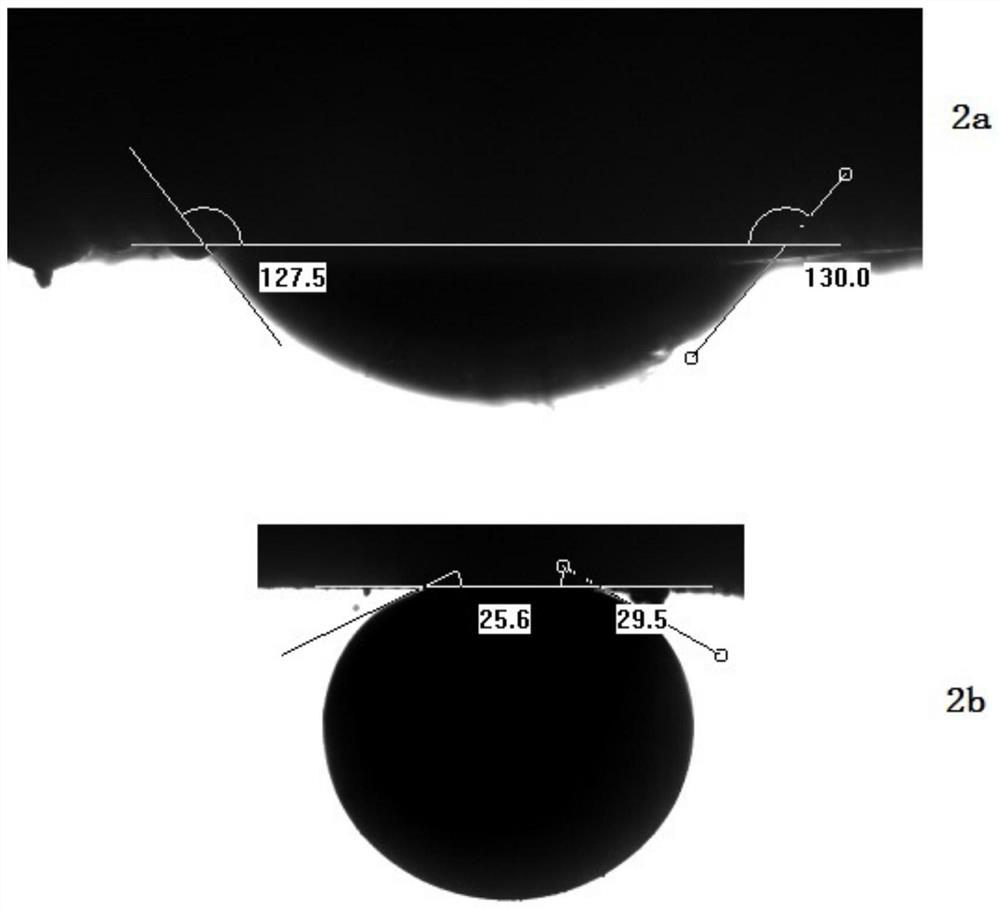

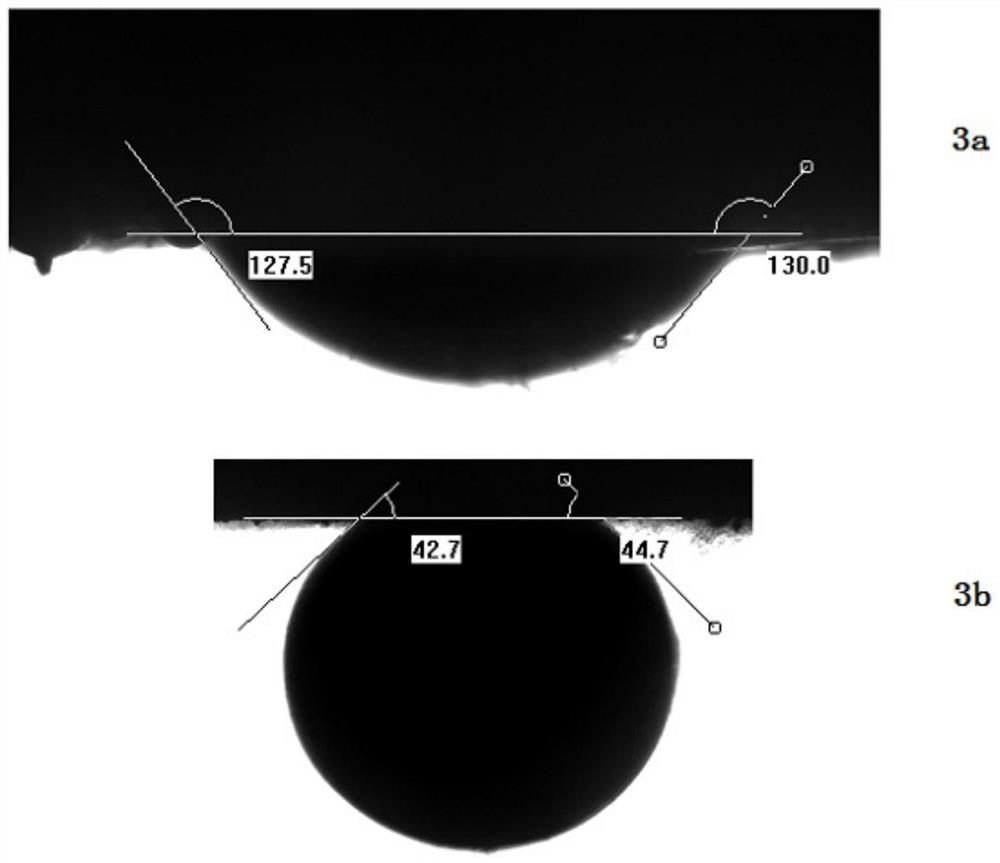

Image

Examples

Embodiment 1

[0061] The present embodiment provides the preparation method of the polymer emulsion of different types, and concrete operation steps are as follows:

[0062] (a) Stir and mix Octylphenol Polyoxyethylene Ether-10 (OP-10), Span-80, Tween 80, and saturated petroleum distillate with a boiling range of 245-255°C, and configure it into an oil phase;

[0063] (b) Add acrylamide (AM) and 2-acrylamido-2-methylpropanesulfonic acid (AMPS) into deionized water to configure a concentration of 30%wt AM+30%wt AMPS solution, using a concentration of 20%wt NaOH solution to adjust the pH to 6, then add 10%wt disodium ethylenediaminetetraacetic acid (EDTA-2Na) solution and tetramethylethylenediamine in turn, and use 20%wt NaOH solution to adjust the pH Be 7 water-soluble, obtain water phase;

[0064] (c) Pour the water phase into the oil phase, emulsify for 20min, and use the No. 63 rotor of the Brookfield DVLV-3 type viscometer at a speed of 30 rpm to perform a liquid viscosity test. The mea...

Embodiment 2

[0070] This example provides a method for preparing a polymer emulsion. The specific operation steps are similar to those of S1-1. The only difference is that no reaction aids EDTA-2Na and tetramethylethylenediamine are added. The model of the polymer emulsion is for S2.

Embodiment 3

[0072] This example provides a method for preparing a polymer emulsion. The specific operation steps are similar to S1-1, the only difference is that AMPS is not added, and the weight part of AM is 60 parts. The model of the polymer emulsion is S3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com