Slipping and brightening functional master batch for biaxially oriented polyamide film and preparation method thereof

A polyamide film and biaxial stretching technology, which is applied in the field of nylon material modification, can solve the problems of poor performance of biaxially stretched polyamide film and cannot meet performance requirements, etc., and achieve excellent smooth opening, good large-scale production and application, Effect of increasing gloss and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

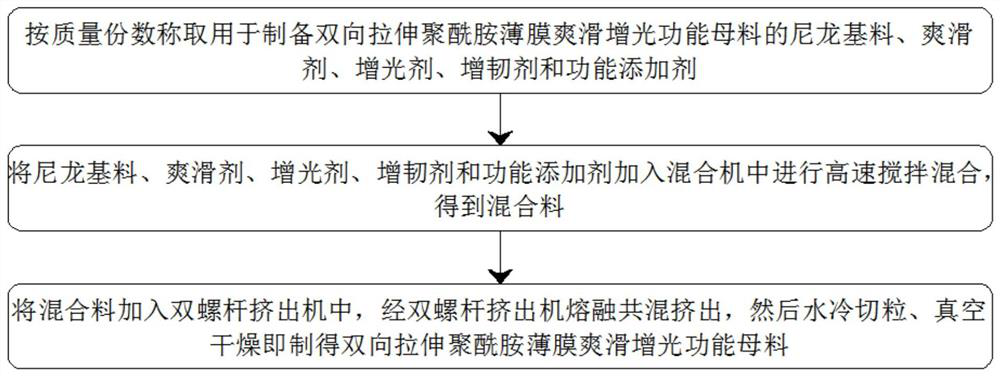

Method used

Image

Examples

Embodiment 1

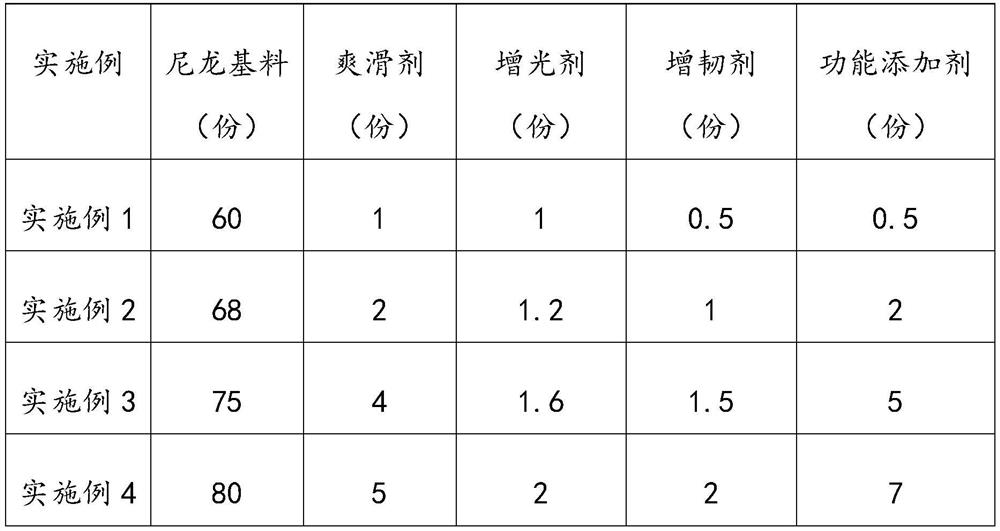

[0026] A biaxially stretched polyamide film smooth and brightening functional masterbatch, the formula of the biaxially stretched polyamide film smooth and brightening functional masterbatch in parts by mass is as follows:

[0027] 60 parts of nylon base material, 1 part of smooth agent, 1 part of brightening agent, 0.5 part of toughening agent and 0.5 part of functional additive.

[0028] As a technical preferred solution of the present invention, the nylon base material is PA6.

[0029] As a technical preferred solution of the present invention, the slip agent is erucamide.

[0030] As a technical preferred solution of the present invention, the brightening agent is an acrylate copolymer.

[0031] As a technical preferred solution of the present invention, the toughening agent is a composition of maleic anhydride grafted ethylene-vinyl acetate copolymer and maleic anhydride grafted ethylene-olefin copolymer, and the mass ratio is 1:1.

[0032] As a kind of technical prefer...

Embodiment 2

[0041] A biaxially stretched polyamide film smooth and brightening functional masterbatch, the formula of the biaxially stretched polyamide film smooth and brightening functional masterbatch in parts by mass is as follows:

[0042] 68 parts of nylon base material, 2 parts of slip agent, 1.2 parts of brightening agent, 1 part of toughening agent and 2 parts of functional additive.

[0043] As a technical preferred solution of the present invention, the nylon base material is a composition of PA6 and PA66, and the mass ratio is 1:1.

[0044] As a technical preferred solution of the present invention, the slip agent is a composition of erucamide and oleamide, and the mass ratio is 3:1.

[0045] As a technical preferred solution of the present invention, the brightening agent is an acrylate copolymer.

[0046] As a technical preferred solution of the present invention, the toughening agent is a composition of maleic anhydride grafted polyethylene and maleic anhydride-styrene copo...

Embodiment 3

[0056] A biaxially stretched polyamide film smooth and brightening functional masterbatch, the formula of the biaxially stretched polyamide film smooth and brightening functional masterbatch in parts by mass is as follows:

[0057] 75 parts of nylon base material, 4 parts of slip agent, 1.6 parts of brightening agent, 1.5 parts of toughening agent and 5 parts of functional additive.

[0058] As a technical preferred solution of the present invention, the nylon base material is a composition of PA6 and PA66, and the mass ratio is 2:1.

[0059] As a technical preferred solution of the present invention, the slip agent is ethylene bisstearamide.

[0060] As a technical preferred solution of the present invention, the brightening agent is an acrylate copolymer.

[0061] As a technical preferred solution of the present invention, the toughening agent is a composition of maleic anhydride grafted ethylene-vinyl acetate copolymer, maleic anhydride grafted ethylene-olefin copolymer an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com