A kind of nitrogen-aluminum co-doped carbon dot film laser protection material and its preparation method and application

A laser protection and co-doping technology, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of unfavorable device processing and device work requirements, achieve good transparency and thermal stability, and enhance nonlinear optical performance , the effect of a large nonlinear absorption coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

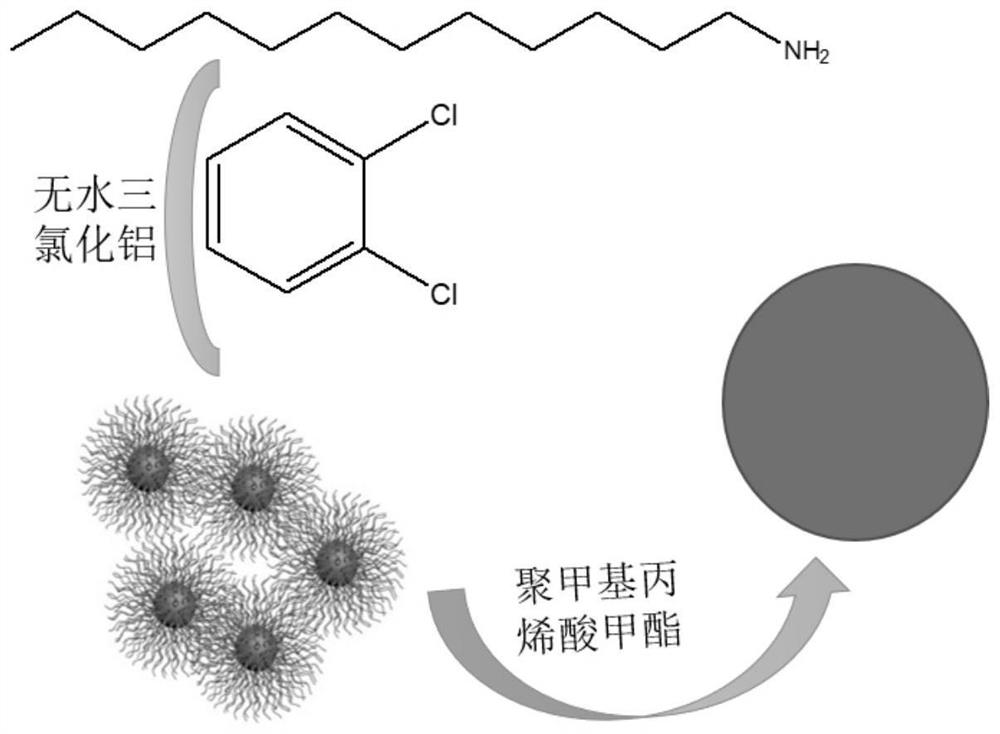

[0043] A preparation method of nitrogen-aluminum co-doped carbon dot film laser protection material, the preparation route is as follows figure 1 As shown, the steps are as follows:

[0044] (1) Weigh 9.3 grams of dodecylamine and 6.2 grams of anhydrous aluminum trichloride into a 250 ml three-neck flask, then add 50 ml of o-dichlorobenzene, mix well, reflux at 140 ° C for 48 hours, and cool After reaching room temperature, the solvent was purified by n-hexane silica gel column, the raw materials and by-products were removed by ethanol silica gel column purification, the eluent was removed by rotary evaporation, and the hydrophobic carbon dots co-doped with nitrogen and aluminum were obtained after vacuum drying at 50°C for 5 days;

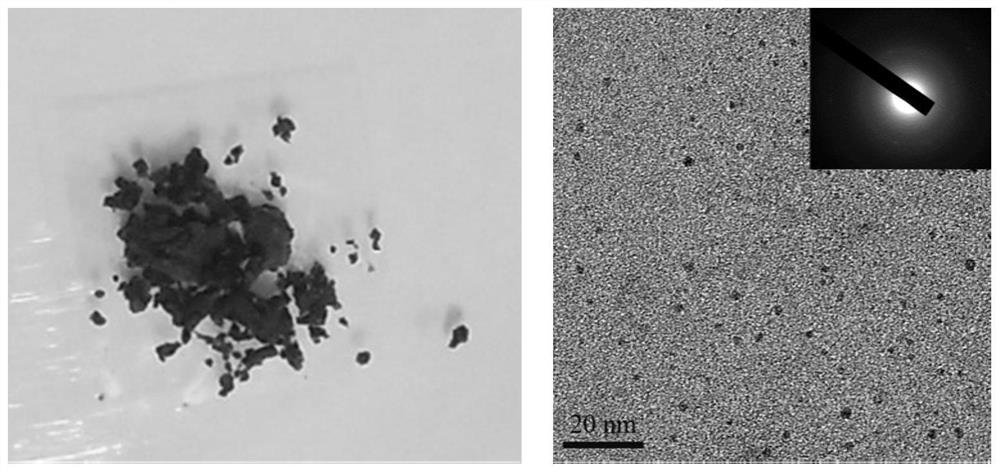

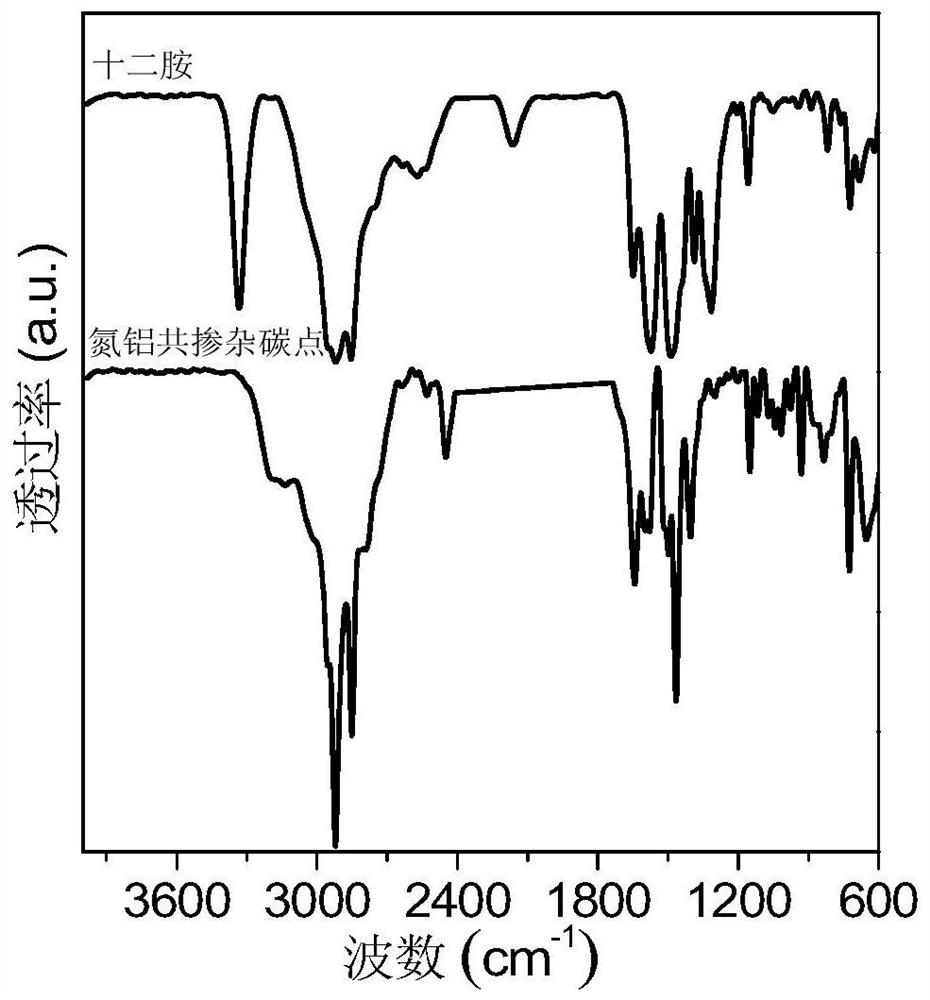

[0045] The solar photos and high-resolution transmission electron microscope of the obtained carbon dots are as follows: figure 2 It can be seen from the figure that the prepared nitrogen-aluminum co-doped hydrophobic carbon dots are in the form...

Embodiment 2

[0055] A preparation method of nitrogen-aluminum co-doped carbon dot film laser protection material, as described in Example 1, the difference is:

[0056] Change the ratio of dodecylamine to anhydrous aluminum chloride to 3:1 (that is, 9.3 grams of dodecylamine and 3.1 grams of anhydrous aluminum chloride); other steps and conditions are consistent with Example 1.

Embodiment 3

[0058] A preparation method of nitrogen-aluminum co-doped carbon dot film laser protection material, as described in Example 1, the difference is:

[0059] Change the ratio of dodecylamine to anhydrous aluminum chloride to 6:1 (that is, 9.3 grams of dodecylamine and 1.5 grams of anhydrous aluminum chloride); other steps and conditions are consistent with those of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com